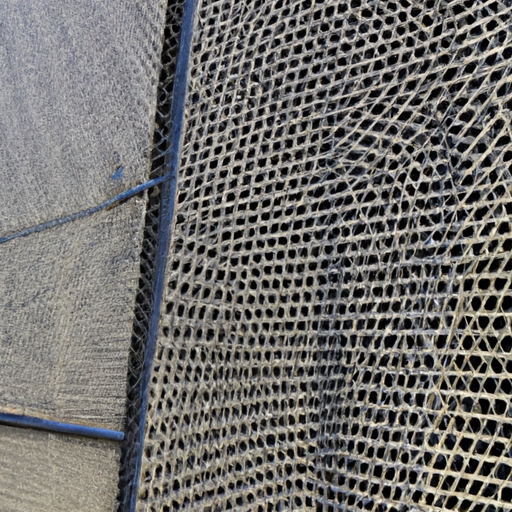

vibrating screen mesh

The Importance of vibrating screen mesh in Industrial Applications The Importance of Vibrating screen mesh in Industrial Applications Vibrating screen mesh plays…

The Importance of vibrating screen mesh in Industrial Applications

The Importance of Vibrating screen mesh in Industrial Applications

Vibrating screen mesh plays a crucial role in various industrial applications. It is an essential component that allows for the efficient separation and classification of materials. From mining and construction to pharmaceuticals and food processing, vibrating screen mesh is used in a wide range of industries to ensure the quality and consistency of products.

One of the primary functions of vibrating screen mesh is to filter and separate materials based on their size. This is particularly important in industries such as mining and construction, where different sizes of materials need to be sorted and classified. By using vibrating screen mesh, larger particles can be separated from smaller ones, ensuring that each material is processed correctly.

In addition to size separation, vibrating screen mesh also helps in the removal of impurities and foreign particles. In industries like pharmaceuticals and food processing, it is crucial to ensure that the final product is free from any contaminants. Vibrating screen mesh with the appropriate aperture size can effectively filter out unwanted particles, ensuring the purity and safety of the end product.

Another significant advantage of vibrating screen mesh is its ability to withstand harsh operating conditions. In industries like mining and quarrying, the vibrating screen mesh is exposed to heavy loads, abrasive materials, and high temperatures. Therefore, it is essential to use high-quality materials that are durable and resistant to wear and tear. This ensures that the vibrating screen mesh can withstand the demanding conditions and maintain its efficiency and performance over time.

Furthermore, vibrating screen mesh offers versatility in terms of customization. Different industries have specific requirements when it comes to the size, shape, and material of the mesh. Vibrating screen mesh can be tailored to meet these specific needs, ensuring optimal performance and efficiency. Whether it is stainless steel, polyurethane, or Woven wire mesh, the choice of material depends on the application and the desired outcome.

The maintenance and cleaning of vibrating screen mesh are also crucial for its effective operation. Over time, the mesh can become clogged with particles, reducing its efficiency. Regular cleaning and maintenance help to prevent blockages and ensure the smooth flow of materials. Additionally, inspecting the mesh for any signs of wear or damage is essential to prevent any potential issues and ensure the longevity of the vibrating screen mesh.

Vibrating screen mesh plays a crucial role in various industrial applications. It is an essential component that allows for the efficient separation and classification of materials. From mining and construction to pharmaceuticals and food processing, vibrating screen mesh is used in a wide range of industries to ensure the quality and consistency of products.

One of the primary functions of vibrating screen mesh is to filter and separate materials based on their size. This is particularly important in industries such as mining and construction, where different sizes of materials need to be sorted and classified. By using vibrating screen mesh, larger particles can be separated from smaller ones, ensuring that each material is processed correctly.

In addition to size separation, vibrating screen mesh also helps in the removal of impurities and foreign particles. In industries like pharmaceuticals and food processing, it is crucial to ensure that the final product is free from any contaminants. Vibrating screen mesh with the appropriate aperture size can effectively filter out unwanted particles, ensuring the purity and safety of the end product.

Another significant advantage of vibrating screen mesh is its ability to withstand harsh operating conditions. In industries like mining and quarrying, the vibrating screen mesh is exposed to heavy loads, abrasive materials, and high temperatures. Therefore, it is essential to use high-quality materials that are durable and resistant to wear and tear. This ensures that the vibrating screen mesh can withstand the demanding conditions and maintain its efficiency and performance over time.

Furthermore, vibrating screen mesh offers versatility in terms of customization. Different industries have specific requirements when it comes to the size, shape, and material of the mesh. Vibrating screen mesh can be tailored to meet these specific needs, ensuring optimal performance and efficiency. Whether it is stainless steel, polyurethane, or Woven wire mesh, the choice of material depends on the application and the desired outcome.

The maintenance and cleaning of vibrating screen mesh are also crucial for its effective operation. Over time, the mesh can become clogged with particles, reducing its efficiency. Regular cleaning and maintenance help to prevent blockages and ensure the smooth flow of materials. Additionally, inspecting the mesh for any signs of wear or damage is essential to prevent any potential issues and ensure the longevity of the vibrating screen mesh.