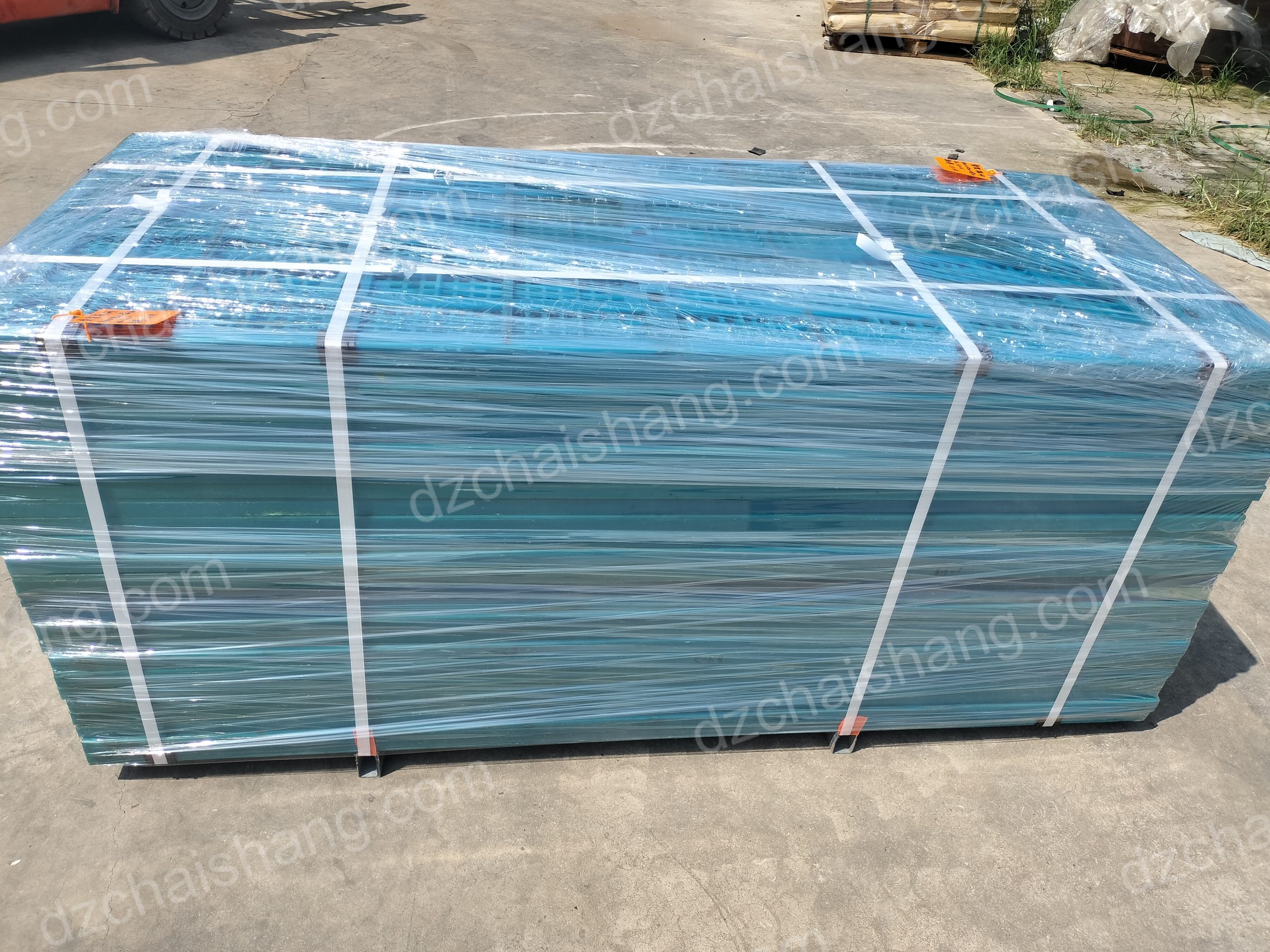

Good quality modular PU panel,modular Polyurethanescreen Custom-made

Benefits of Using Good Quality Modular PU Panels for Industrial Applications Modular PU panels, also known as modular polyurethane screens, are a…

Benefits of Using Good Quality Modular PU Panels for Industrial Applications

Modular PU panels, also known as modular polyurethane screens, are a popular choice for industrial applications due to their durability, versatility, and ease of installation. These panels are made from high-quality polyurethane material, which offers a range of benefits for various industries. In this article, we will explore the advantages of using good quality modular PU panels for industrial applications. One of the key benefits of modular PU panels is their durability. These panels are designed to withstand harsh conditions, including high temperatures, heavy loads, and abrasive materials. This makes them ideal for use in industries such as mining, construction, and agriculture, where equipment is subjected to extreme wear and tear. The polyurethane material used in these panels is resistant to chemicals, oils, and solvents, ensuring that they will not degrade or break down over time.

In addition to their durability, modular PU panels are also highly versatile. These panels can be custom-made to fit any size or shape, making them suitable for a wide range of applications. Whether you need a small panel for a specific piece of equipment or a large panel for a screening system, modular PU panels can be tailored to meet your exact requirements. This flexibility makes them a cost-effective solution for industrial applications, as they can be easily adapted to suit different needs.

Another advantage of using good quality modular PU panels is their ease of installation. These panels are designed to be lightweight and easy to handle, making them quick and simple to install. This can help to reduce downtime and increase productivity, as equipment can be up and running in no time. Additionally, modular PU panels can be easily removed and replaced, allowing for quick maintenance and repairs when needed.

Furthermore, modular PU panels offer excellent screening performance. The polyurethane material used in these panels is highly flexible, allowing for efficient screening of materials of varying sizes and shapes. This makes them ideal for use in industries such as mining and aggregates, where accurate screening is essential for product quality. The modular design of these panels also allows for easy cleaning and maintenance, ensuring that they will continue to perform at their best for years to come.

Overall, good quality modular PU panels offer a range of benefits for industrial applications. Their durability, versatility, ease of installation, and screening performance make them an ideal choice for a wide range of industries. Whether you need a custom-made panel for a specific application or a standard panel for general use, modular PU panels can provide a cost-effective and efficient solution. With their high-quality construction and long-lasting performance, modular PU panels are sure to meet the needs of even the most demanding industrial applications.

One of the key benefits of modular PU panels is their durability. These panels are designed to withstand harsh conditions, including high temperatures, heavy loads, and abrasive materials. This makes them ideal for use in industries such as mining, construction, and agriculture, where equipment is subjected to extreme wear and tear. The polyurethane material used in these panels is resistant to chemicals, oils, and solvents, ensuring that they will not degrade or break down over time.

In addition to their durability, modular PU panels are also highly versatile. These panels can be custom-made to fit any size or shape, making them suitable for a wide range of applications. Whether you need a small panel for a specific piece of equipment or a large panel for a screening system, modular PU panels can be tailored to meet your exact requirements. This flexibility makes them a cost-effective solution for industrial applications, as they can be easily adapted to suit different needs.

Another advantage of using good quality modular PU panels is their ease of installation. These panels are designed to be lightweight and easy to handle, making them quick and simple to install. This can help to reduce downtime and increase productivity, as equipment can be up and running in no time. Additionally, modular PU panels can be easily removed and replaced, allowing for quick maintenance and repairs when needed.

Furthermore, modular PU panels offer excellent screening performance. The polyurethane material used in these panels is highly flexible, allowing for efficient screening of materials of varying sizes and shapes. This makes them ideal for use in industries such as mining and aggregates, where accurate screening is essential for product quality. The modular design of these panels also allows for easy cleaning and maintenance, ensuring that they will continue to perform at their best for years to come.

Overall, good quality modular PU panels offer a range of benefits for industrial applications. Their durability, versatility, ease of installation, and screening performance make them an ideal choice for a wide range of industries. Whether you need a custom-made panel for a specific application or a standard panel for general use, modular PU panels can provide a cost-effective and efficient solution. With their high-quality construction and long-lasting performance, modular PU panels are sure to meet the needs of even the most demanding industrial applications.

How to Design Custom-Made Modular Polyurethane Screens for Specific Screening Needs

Modular polyurethane screens are a versatile and durable solution for a wide range of screening applications. These screens are made from high-quality polyurethane material, which offers excellent wear resistance, flexibility, and chemical resistance. One of the key advantages of modular polyurethane screens is their ability to be custom-made to suit specific screening needs. By designing custom-made modular polyurethane screens, you can ensure optimal performance and efficiency in your screening process. When designing custom-made modular polyurethane screens, it is important to consider the specific requirements of your screening application. This includes factors such as the size and shape of the screening area, the type of material being screened, and the desired screening efficiency. By understanding these requirements, you can work with a manufacturer to create a screen that is tailored to your exact specifications. One of the first steps in designing custom-made modular polyurethane screens is to determine the size and shape of the screening area. This will help you determine the overall dimensions of the screen panels, as well as the number of panels needed to cover the entire screening area. By accurately measuring the screening area, you can ensure that the custom-made screens fit perfectly and provide maximum coverage.

In addition to size and shape, it is important to consider the type of material being screened when designing custom-made modular polyurethane screens. Different materials have different properties, such as particle size, abrasiveness, and moisture content, which can affect the performance of the screening process. By understanding the characteristics of the material being screened, you can select the appropriate screen aperture size and design features to optimize screening efficiency.

One of the first steps in designing custom-made modular polyurethane screens is to determine the size and shape of the screening area. This will help you determine the overall dimensions of the screen panels, as well as the number of panels needed to cover the entire screening area. By accurately measuring the screening area, you can ensure that the custom-made screens fit perfectly and provide maximum coverage.

In addition to size and shape, it is important to consider the type of material being screened when designing custom-made modular polyurethane screens. Different materials have different properties, such as particle size, abrasiveness, and moisture content, which can affect the performance of the screening process. By understanding the characteristics of the material being screened, you can select the appropriate screen aperture size and design features to optimize screening efficiency.