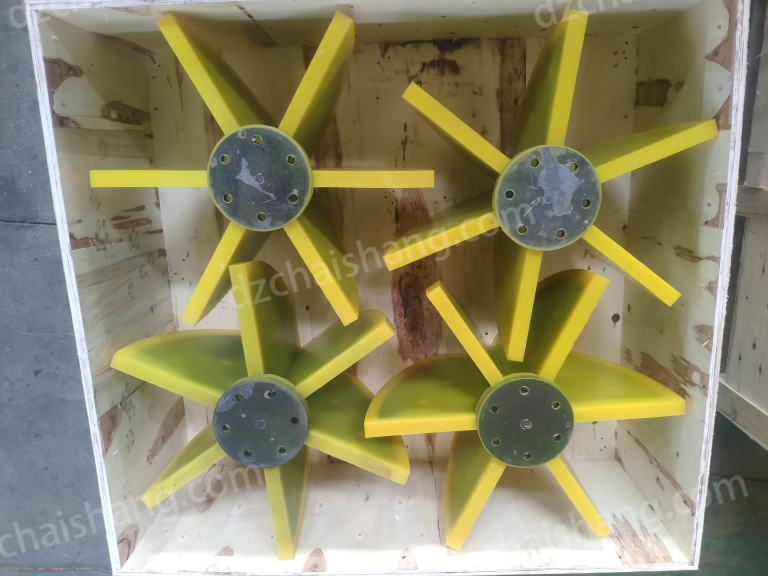

lowest price vibrating flip flop Urethane sieve minerial

Benefits of Using Low Price Vibrating Flip Flop urethane Sieve in Mineral Processing In the world of mineral processing, efficiency and cost-effectiveness…

Benefits of Using Low Price Vibrating Flip Flop urethane Sieve in Mineral Processing

In the world of mineral processing, efficiency and cost-effectiveness are key factors in ensuring the success of operations. One crucial component in this process is the vibrating flip flop urethane sieve, which plays a vital role in separating and classifying materials. These sieves are designed to withstand the harsh conditions of mineral processing, providing a reliable and durable solution for industries looking to optimize their operations. One of the primary benefits of using a low price vibrating flip flop urethane sieve in mineral processing is its ability to efficiently separate materials. The unique design of these sieves allows for high-frequency vibrations that effectively separate particles based on size and shape. This results in a more precise classification of materials, leading to improved efficiency and productivity in mineral processing operations. Additionally, vibrating flip flop urethane sieves are known for their durability and longevity. Made from high-quality urethane material, these sieves are resistant to wear and tear, making them ideal for the demanding conditions of mineral processing. This durability not only reduces maintenance costs but also ensures a longer lifespan for the sieve, ultimately saving money in the long run. Another key benefit of using a low price vibrating flip flop urethane sieve is its versatility. These sieves can be customized to meet specific processing requirements, allowing industries to tailor their equipment to suit their unique needs. Whether it’s adjusting the amplitude of vibrations or changing the screen size, these sieves offer flexibility and adaptability for a wide range of applications in mineral processing. Furthermore, vibrating flip flop urethane sieves are known for their energy efficiency. By utilizing high-frequency vibrations, these sieves require less power to operate compared to traditional screening equipment. This not only reduces energy costs but also minimizes the environmental impact of mineral processing operations, making them a more sustainable choice for industries looking to reduce their carbon footprint.

In addition to their efficiency and cost-effectiveness, low price vibrating flip flop urethane sieves also offer improved safety benefits. The design of these sieves minimizes the risk of material buildup and blockages, reducing the likelihood of accidents and injuries in the workplace. This enhanced safety feature is crucial for industries prioritizing the well-being of their employees and ensuring compliance with industry regulations.

Furthermore, vibrating flip flop urethane sieves are known for their energy efficiency. By utilizing high-frequency vibrations, these sieves require less power to operate compared to traditional screening equipment. This not only reduces energy costs but also minimizes the environmental impact of mineral processing operations, making them a more sustainable choice for industries looking to reduce their carbon footprint.

In addition to their efficiency and cost-effectiveness, low price vibrating flip flop urethane sieves also offer improved safety benefits. The design of these sieves minimizes the risk of material buildup and blockages, reducing the likelihood of accidents and injuries in the workplace. This enhanced safety feature is crucial for industries prioritizing the well-being of their employees and ensuring compliance with industry regulations.