Polyurethane screen plate manufacturer explains what polyurethane screen plate is used for

Benefits of Using polyurethane screen Plates in mining Operations Polyurethane screen plates have become a popular choice in the mining industry due…

Benefits of Using polyurethane screen Plates in mining Operations

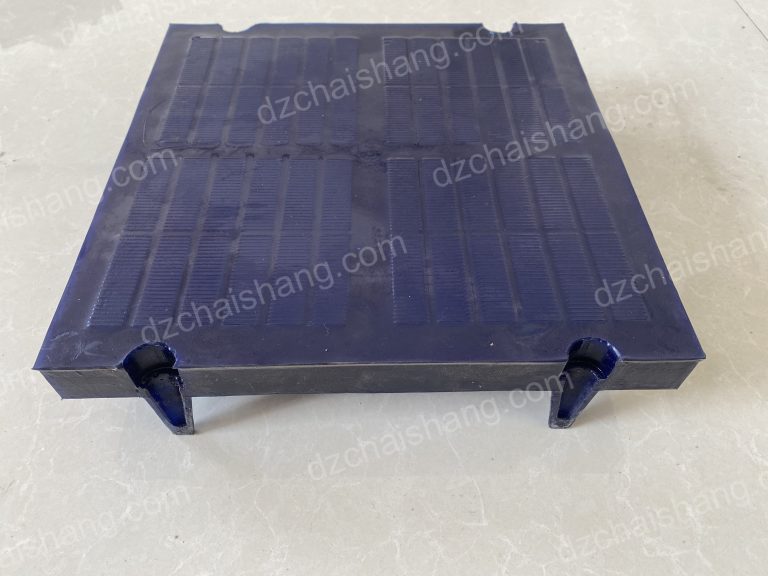

Polyurethane screen plates have become a popular choice in the mining industry due to their numerous benefits and advantages over traditional steel or rubber screen plates. These innovative screen plates are made from polyurethane, a versatile material known for its durability, flexibility, and resistance to wear and tear. In this article, we will explore the various applications and uses of polyurethane screen plates in mining operations. One of the primary uses of polyurethane screen plates in mining is for screening and separating materials. These screen plates are designed to efficiently separate particles of different sizes, allowing for the classification of materials based on their size and shape. This is essential in mining operations, where the quality and consistency of the final product depend on the accurate separation of materials. Polyurethane screen plates are also used for dewatering applications in mining operations. These screen plates are designed to remove excess moisture from materials, allowing for more efficient processing and handling of materials. By using polyurethane screen plates for dewatering, mining companies can reduce the amount of water used in their operations and minimize the environmental impact of their activities.How Polyurethane Screen Plates Improve Efficiency in Aggregate Processing

Polyurethane screen plates are a crucial component in the aggregate processing industry. These plates are used in vibrating screens to separate and classify materials such as gravel, sand, and crushed stone. The use of polyurethane screen plates offers several advantages over traditional steel or rubber screen plates. In this article, we will explore the benefits of polyurethane screen plates and how they can improve efficiency in aggregate processing. One of the key advantages of polyurethane screen plates is their durability. Polyurethane is a tough and resilient material that can withstand the harsh conditions of aggregate processing. Unlike steel screen plates, polyurethane screen plates are resistant to abrasion, corrosion, and impact. This means that they have a longer lifespan and require less maintenance, saving time and money for aggregate producers. Another benefit of polyurethane screen plates is their flexibility. Polyurethane is a highly elastic material that can be molded into various shapes and sizes to suit different screening applications. This flexibility allows for greater customization and optimization of the screening process, resulting in higher efficiency and productivity.

Polyurethane screen plates also offer superior screening performance. The fine apertures of polyurethane screen plates provide high screening efficiency and accuracy, ensuring that only the desired materials pass through the screen. This results in a higher quality of final product and reduces the amount of waste material that needs to be processed.

In addition to their durability, flexibility, and screening performance, polyurethane screen plates are also lightweight and easy to install. This makes them ideal for use in portable screening plants and mobile crushers, where quick and easy maintenance is essential. Polyurethane screen plates can be easily replaced or repaired on-site, minimizing downtime and maximizing production output.

Overall, polyurethane screen plates are a cost-effective solution for improving efficiency in aggregate processing. Their durability, flexibility, screening performance, and ease of installation make them a superior choice for screening applications in the aggregate industry. By investing in polyurethane screen plates, aggregate producers can increase their productivity, reduce maintenance costs, and improve the quality of their final product.

In conclusion, polyurethane screen plates are a versatile and efficient solution for aggregate processing. Their unique properties make them an ideal choice for screening applications in the aggregate industry. By using polyurethane screen plates, aggregate producers can achieve higher efficiency, productivity, and quality in their operations. If you are looking to improve the efficiency of your aggregate processing plant, consider investing in polyurethane screen plates from a reputable manufacturer.

Another benefit of polyurethane screen plates is their flexibility. Polyurethane is a highly elastic material that can be molded into various shapes and sizes to suit different screening applications. This flexibility allows for greater customization and optimization of the screening process, resulting in higher efficiency and productivity.

Polyurethane screen plates also offer superior screening performance. The fine apertures of polyurethane screen plates provide high screening efficiency and accuracy, ensuring that only the desired materials pass through the screen. This results in a higher quality of final product and reduces the amount of waste material that needs to be processed.

In addition to their durability, flexibility, and screening performance, polyurethane screen plates are also lightweight and easy to install. This makes them ideal for use in portable screening plants and mobile crushers, where quick and easy maintenance is essential. Polyurethane screen plates can be easily replaced or repaired on-site, minimizing downtime and maximizing production output.

Overall, polyurethane screen plates are a cost-effective solution for improving efficiency in aggregate processing. Their durability, flexibility, screening performance, and ease of installation make them a superior choice for screening applications in the aggregate industry. By investing in polyurethane screen plates, aggregate producers can increase their productivity, reduce maintenance costs, and improve the quality of their final product.

In conclusion, polyurethane screen plates are a versatile and efficient solution for aggregate processing. Their unique properties make them an ideal choice for screening applications in the aggregate industry. By using polyurethane screen plates, aggregate producers can achieve higher efficiency, productivity, and quality in their operations. If you are looking to improve the efficiency of your aggregate processing plant, consider investing in polyurethane screen plates from a reputable manufacturer.