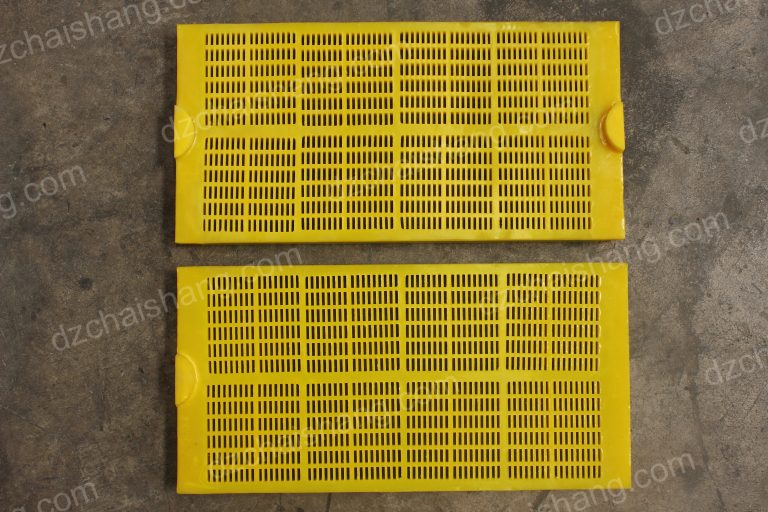

direct sales vibrating high frequency Rubber plate Dewatering

Benefits of Using high frequency Rubber Plates in Direct Sales Direct sales vibrating high frequency rubber plate dewatering is a process that…

Benefits of Using high frequency Rubber Plates in Direct Sales

Direct sales vibrating high frequency rubber plate dewatering is a process that has revolutionized the way industries handle their dewatering needs. This innovative technology offers numerous benefits that make it a preferred choice for many businesses. In this article, we will explore the advantages of using high frequency rubber plates in direct sales and how they can improve efficiency and productivity in various industries. One of the key benefits of using high frequency rubber plates in direct sales is their ability to efficiently remove water from solid materials. The high frequency vibrations generated by the rubber plates help to separate water from the solids, resulting in a drier end product. This not only reduces the amount of water that needs to be disposed of but also improves the quality of the final product. Another advantage of using high frequency rubber plates in direct sales is their versatility. These plates can be used in a wide range of applications, from dewatering sludge in wastewater treatment plants to separating solids in mining operations. Their flexibility makes them a valuable tool for businesses looking to streamline their dewatering processes and improve overall efficiency. In addition to their efficiency and versatility, high frequency rubber plates also offer cost savings for businesses. By reducing the amount of water that needs to be disposed of and improving the quality of the final product, businesses can save money on waste disposal and increase their overall profitability. This makes high frequency rubber plates a smart investment for businesses looking to improve their bottom line. Furthermore, high frequency rubber plates are easy to operate and maintain, making them a practical choice for businesses of all sizes. Their simple design and user-friendly interface make them accessible to operators with varying levels of experience, while their durable construction ensures long-lasting performance with minimal maintenance requirements. The use of high frequency rubber plates in direct sales also has environmental benefits. By reducing the amount of water that needs to be disposed of, businesses can minimize their impact on the environment and reduce their carbon footprint. This makes high frequency rubber plates a sustainable choice for businesses looking to improve their environmental performance. Overall, the benefits of using high frequency rubber plates in direct sales are clear. From improved efficiency and productivity to cost savings and environmental benefits, these innovative dewatering solutions offer a range of advantages for businesses in various industries. By investing in high frequency rubber plates, businesses can streamline their dewatering processes, improve the quality of their products, and enhance their overall profitability.How to Maximize Dewatering Efficiency with High Frequency Rubber Plates in Direct Sales

Dewatering is a crucial process in many industries, including mining, construction, and wastewater treatment. It involves removing water from solid materials or sludge to reduce volume and weight, making disposal or further processing easier and more cost-effective. One effective way to maximize dewatering efficiency is by using high frequency rubber plates in direct sales. High frequency rubber plates are designed to vibrate at a high frequency, which helps to separate water from solid materials more effectively. When used in dewatering applications, these plates can significantly increase the speed and efficiency of the process, resulting in faster processing times and higher yields. One of the key benefits of using high frequency rubber plates in dewatering is their ability to remove water from materials that are difficult to dewater using traditional methods. The high frequency vibrations help to break up the water molecules, allowing them to be easily separated from the solid materials. This is particularly useful in industries where the materials being dewatered are highly viscous or contain a high percentage of water. In addition to their effectiveness in separating water from solid materials, high frequency rubber plates also offer other advantages in dewatering applications. For example, they are easy to install and maintain, making them a cost-effective solution for businesses looking to improve their dewatering processes. They are also durable and long-lasting, ensuring that they will continue to perform well over time. Another benefit of using high frequency rubber plates in dewatering is their ability to reduce energy consumption. Because they operate at a high frequency, these plates require less energy to achieve the same level of dewatering as traditional methods. This can result in significant cost savings for businesses, particularly those that operate dewatering equipment on a large scale. Overall, high frequency rubber plates offer a highly effective and efficient solution for businesses looking to maximize their dewatering efficiency. By using these plates in direct sales, businesses can improve their dewatering processes, reduce energy consumption, and increase their overall productivity. With their ease of installation and maintenance, durability, and cost-effectiveness, high frequency rubber plates are an excellent choice for businesses in need of a reliable dewatering solution.

Overall, high frequency rubber plates offer a highly effective and efficient solution for businesses looking to maximize their dewatering efficiency. By using these plates in direct sales, businesses can improve their dewatering processes, reduce energy consumption, and increase their overall productivity. With their ease of installation and maintenance, durability, and cost-effectiveness, high frequency rubber plates are an excellent choice for businesses in need of a reliable dewatering solution.