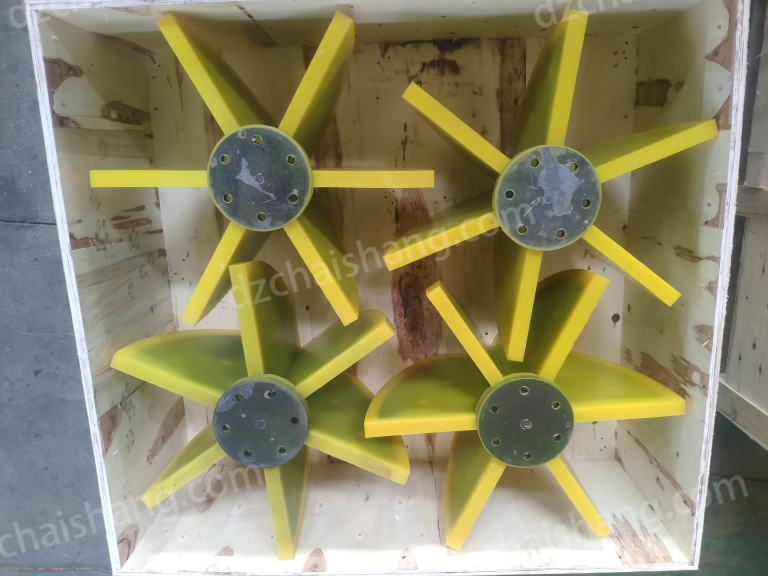

vibrator high frequency Polyurethane screen Customization Mining

Benefits of Using high frequency polyurethane screens in mining Operations High frequency polyurethane screens have become increasingly popular in the mining industry…

Benefits of Using high frequency polyurethane screens in mining Operations

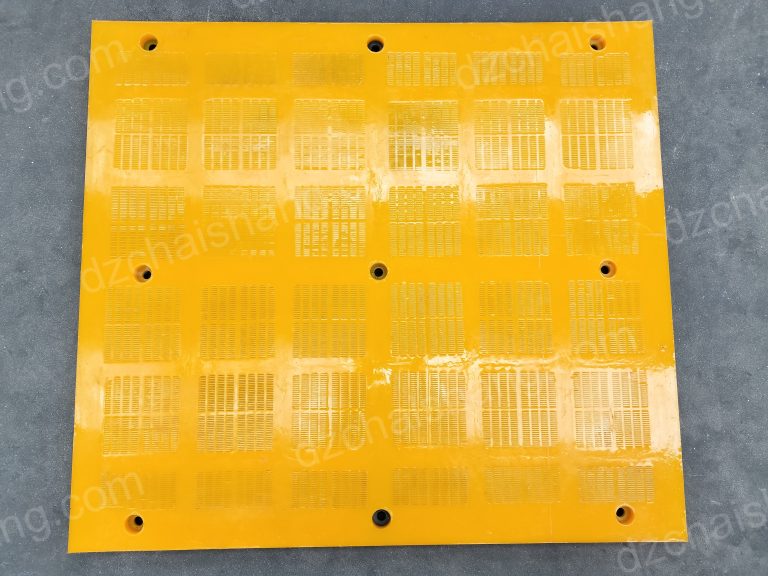

High frequency polyurethane screens have become increasingly popular in the mining industry due to their numerous benefits and advantages. These screens are designed to withstand the harsh conditions of mining operations while providing efficient and effective screening of materials. In this article, we will explore the benefits of using high frequency polyurethane screens in mining operations. One of the key advantages of high frequency polyurethane screens is their durability and longevity. These screens are made from high-quality polyurethane material that is resistant to abrasion, corrosion, and impact. This means that they can withstand the wear and tear of constant use in mining operations without needing frequent replacements. As a result, mining companies can save time and money on maintenance and replacement costs. In addition to their durability, high frequency polyurethane screens are also highly efficient in screening materials. These screens have a high frequency vibration that helps to separate materials quickly and effectively. This results in a more efficient screening process, allowing mining companies to process more materials in less time. The high frequency vibration also helps to prevent blinding and pegging, which can occur with traditional screens, further improving the efficiency of the screening process. Another benefit of using high frequency polyurethane screens in mining operations is their customization options. These screens can be customized to meet the specific needs and requirements of each mining operation. This includes the size, shape, and configuration of the screen, as well as the aperture size and pattern. By customizing the screens to fit the specific materials being processed, mining companies can achieve optimal screening results and maximize their productivity. Furthermore, high frequency polyurethane screens are easy to install and maintain. These screens are lightweight and flexible, making them easy to handle and install in various mining applications. Additionally, the polyurethane material is easy to clean and maintain, ensuring that the screens remain in optimal condition for longer periods of time. This ease of installation and maintenance helps to minimize downtime and maximize the efficiency of mining operations. In conclusion, high frequency polyurethane screens offer numerous benefits for mining operations. From their durability and efficiency to their customization options and ease of installation, these screens are a valuable asset for any mining company looking to improve their screening process. By investing in high frequency polyurethane screens, mining companies can increase their productivity, reduce maintenance costs, and achieve optimal screening results. Overall, high frequency polyurethane screens are a smart choice for mining operations looking to enhance their screening capabilities and maximize their efficiency.How to Customize Vibrator High Frequency Polyurethane Screens for Optimal Performance in Mining Applications

Vibrator high frequency polyurethane screens are essential components in the mining industry, as they play a crucial role in the screening and classification of materials. These screens are designed to withstand the harsh conditions of mining operations, providing efficient and reliable performance. However, to ensure optimal performance, it is important to customize these screens according to the specific requirements of each mining application. Customization of vibrator high frequency polyurethane screens involves tailoring the screen size, aperture size, and panel thickness to meet the unique needs of the mining operation. By customizing these screens, mining companies can improve screening efficiency, reduce downtime, and increase overall productivity. One of the key factors to consider when customizing vibrator high frequency polyurethane screens is the screen size. The size of the screen will determine the amount of material that can be processed at a given time. By selecting the appropriate screen size, mining companies can maximize throughput and ensure that the screening process is as efficient as possible.

One of the key factors to consider when customizing vibrator high frequency polyurethane screens is the screen size. The size of the screen will determine the amount of material that can be processed at a given time. By selecting the appropriate screen size, mining companies can maximize throughput and ensure that the screening process is as efficient as possible.