聚氨酯篩板廠商講解聚氨酯篩板的用途是什麼

在採礦作業中使用聚氨酯篩板的好處 聚氨酯篩板如何提高骨材加工效率 聚氨酯篩板的另一個優點是其彈性。聚氨酯是一種高彈性材料,可以模製成各種形狀和尺寸,以適應不同的篩選應用。這種靈活性允許對篩選過程進行更大程度的客製化和優化,從而提高效率和生產率。聚氨酯篩板的細孔徑提供了高篩分效率和精度,確保只有所需的物料通過篩子。這可以提高最終產品的質量,並減少需要處理的廢料量。這使得它們非常適合用於便攜式篩選設備和移動破碎機,在這些設備中,快速、輕鬆的維護至關重要。聚氨酯篩板可以輕鬆地在現場更換或維修,從而最大限度地減少停機時間並最大限度地提高產量。它們的耐用性、靈活性、篩分性能和易於安裝使其成為骨料行業篩分應用的最佳選擇。透過投資聚氨酯篩板,骨材生產商可以提高生產率、降低維護成本並提高最終產品的品質。其獨特的性能使其成為骨料行業篩選應用的理想選擇。透過使用聚氨酯篩板,骨材生產商可以在營運中實現更高的效率、生產率和品質。如果您希望提高骨材加工廠的效率,請考慮投資知名製造商生產的聚氨酯篩板。 How polyurethane screen Plates Improve Efficiency in Aggregate Processing Polyurethane screen plates are a crucial component in the aggregate…

在採礦作業中使用聚氨酯篩板的好處

聚氨酯篩板如何提高骨材加工效率

聚氨酯篩板的另一個優點是其彈性。聚氨酯是一種高彈性材料,可以模製成各種形狀和尺寸,以適應不同的篩選應用。這種靈活性允許對篩選過程進行更大程度的客製化和優化,從而提高效率和生產率。聚氨酯篩板的細孔徑提供了高篩分效率和精度,確保只有所需的物料通過篩子。這可以提高最終產品的質量,並減少需要處理的廢料量。這使得它們非常適合用於便攜式篩選設備和移動破碎機,在這些設備中,快速、輕鬆的維護至關重要。聚氨酯篩板可以輕鬆地在現場更換或維修,從而最大限度地減少停機時間並最大限度地提高產量。它們的耐用性、靈活性、篩分性能和易於安裝使其成為骨料行業篩分應用的最佳選擇。透過投資聚氨酯篩板,骨材生產商可以提高生產率、降低維護成本並提高最終產品的品質。其獨特的性能使其成為骨料行業篩選應用的理想選擇。透過使用聚氨酯篩板,骨材生產商可以在營運中實現更高的效率、生產率和品質。如果您希望提高骨材加工廠的效率,請考慮投資知名製造商生產的聚氨酯篩板。

How polyurethane screen Plates Improve Efficiency in Aggregate Processing

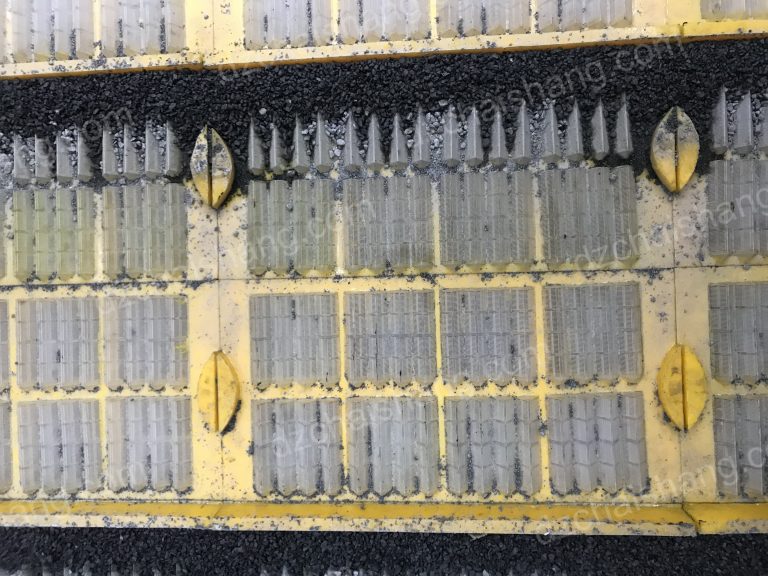

Polyurethane screen plates are a crucial component in the aggregate processing industry. These plates are used in vibrating screens to separate and classify materials such as gravel, sand, and crushed stone. The use of polyurethane screen plates offers several advantages over traditional steel or rubber screen plates. In this article, we will explore the benefits of polyurethane screen plates and how they can improve efficiency in aggregate processing.

One of the key advantages of polyurethane screen plates is their durability. Polyurethane is a tough and resilient material that can withstand the harsh conditions of aggregate processing. Unlike steel screen plates, polyurethane screen plates are resistant to abrasion, corrosion, and impact. This means that they have a longer lifespan and require less maintenance, saving time and money for aggregate producers.

Another benefit of polyurethane screen plates is their flexibility. Polyurethane is a highly elastic material that can be molded into various shapes and sizes to suit different screening applications. This flexibility allows for greater customization and optimization of the screening process, resulting in higher efficiency and productivity.

Polyurethane screen plates also offer superior screening performance. The fine apertures of polyurethane screen plates provide high screening efficiency and accuracy, ensuring that only the desired materials pass through the screen. This results in a higher quality of final product and reduces the amount of waste material that needs to be processed.

In addition to their durability, flexibility, and screening performance, polyurethane screen plates are also lightweight and easy to install. This makes them ideal for use in portable screening plants and mobile crushers, where quick and easy maintenance is essential. Polyurethane screen plates can be easily replaced or repaired on-site, minimizing downtime and maximizing production output.

Overall, polyurethane screen plates are a cost-effective solution for improving efficiency in aggregate processing. Their durability, flexibility, screening performance, and ease of installation make them a superior choice for screening applications in the aggregate industry. By investing in polyurethane screen plates, aggregate producers can increase their productivity, reduce maintenance costs, and improve the quality of their final product.

In conclusion, polyurethane screen plates are a versatile and efficient solution for aggregate processing. Their unique properties make them an ideal choice for screening applications in the aggregate industry. By using polyurethane screen plates, aggregate producers can achieve higher efficiency, productivity, and quality in their operations. If you are looking to improve the efficiency of your aggregate processing plant, consider investing in polyurethane screen plates from a reputable manufacturer.