sieving machine vibrating

The Benefits of Using a Vibrating Sieving Machine The Benefits of Using a Vibrating Sieving Machine In various industries, the process of…

The Benefits of Using a Vibrating Sieving Machine

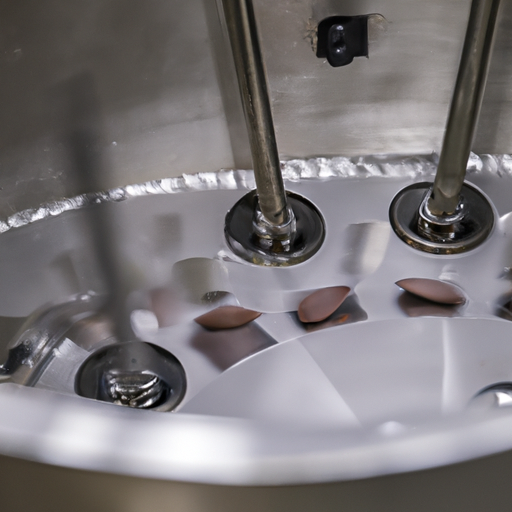

The Benefits of Using a Vibrating Sieving Machine In various industries, the process of separating particles of different sizes is crucial. This is where a vibrating sieving machine comes into play. This machine, also known as a vibrating screen or separator, is designed to efficiently and effectively separate materials based on their size. By utilizing vibration, this machine can quickly and accurately sift through particles, ensuring that only the desired size passes through. One of the key benefits of using a vibrating sieving machine is its ability to increase productivity. Traditional methods of particle separation, such as manual sorting or using static screens, can be time-consuming and labor-intensive. With a vibrating sieving machine, the process is automated, saving both time and effort. The machine can handle large volumes of material, allowing for a higher throughput and faster processing times. This increased productivity can lead to significant cost savings for businesses. Another advantage of using a vibrating sieving machine is its versatility. These machines can be used in a wide range of industries, including pharmaceuticals, food processing, mining, and construction. They can effectively separate a variety of materials, such as powders, granules, liquids, and solids. The machine can be customized to meet specific requirements, such as the desired particle size range or the type of material being processed. This flexibility makes the vibrating sieving machine a valuable tool for many different applications.

In conclusion, the benefits of using a vibrating sieving machine are numerous. From increased productivity and versatility to improved accuracy and safety, this machine offers a valuable solution for particle separation in various industries. By investing in a vibrating sieving machine, businesses can streamline their processes, save time and money, and ensure a high-quality end product.

In conclusion, the benefits of using a vibrating sieving machine are numerous. From increased productivity and versatility to improved accuracy and safety, this machine offers a valuable solution for particle separation in various industries. By investing in a vibrating sieving machine, businesses can streamline their processes, save time and money, and ensure a high-quality end product.