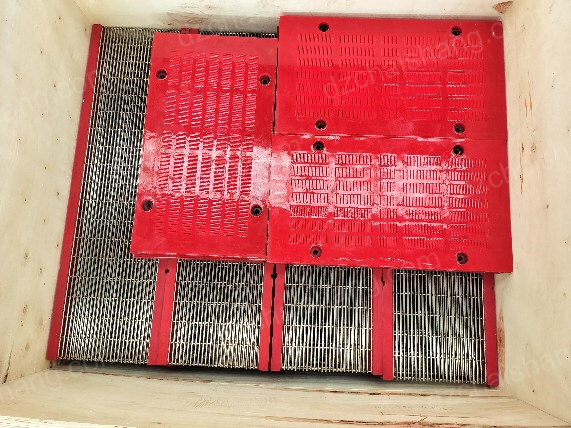

outright sale shaker Polyurethane high frequency sieve

Advantages of Using polyurethane high frequency Sieve for Outright Sale Shaker Polyurethane high frequency sieves have become increasingly popular in the mining…

Advantages of Using polyurethane high frequency Sieve for Outright Sale Shaker

Polyurethane high frequency sieves have become increasingly popular in the mining and aggregate industries due to their numerous advantages over traditional metal sieves. One of the main benefits of using polyurethane high frequency sieves is their durability. Unlike metal sieves, which are prone to corrosion and wear, polyurethane sieves are resistant to abrasion and chemicals, making them ideal for harsh operating conditions. In addition to their durability, polyurethane high frequency sieves are also lightweight and easy to handle. This makes them easier to transport and install, saving time and labor costs. Furthermore, polyurethane sieves are flexible and can be easily molded to fit different screen sizes and shapes, allowing for greater customization and efficiency in the screening process. Overall, the advantages of using polyurethane high frequency sieves for outright sale shakers are clear. From their durability and flexibility to their high screening efficiency and noise reduction properties, polyurethane sieves offer numerous benefits that can improve the overall efficiency and productivity of a screening operation.

In conclusion, polyurethane high frequency sieves are a superior alternative to traditional metal sieves for outright sale shakers. Their durability, flexibility, high screening efficiency, noise reduction properties, and environmental friendliness make them an ideal choice for companies looking to improve their screening processes. By investing in polyurethane high frequency sieves, companies can expect to see increased productivity, higher quality end products, and a more sustainable operation.

Overall, the advantages of using polyurethane high frequency sieves for outright sale shakers are clear. From their durability and flexibility to their high screening efficiency and noise reduction properties, polyurethane sieves offer numerous benefits that can improve the overall efficiency and productivity of a screening operation.

In conclusion, polyurethane high frequency sieves are a superior alternative to traditional metal sieves for outright sale shakers. Their durability, flexibility, high screening efficiency, noise reduction properties, and environmental friendliness make them an ideal choice for companies looking to improve their screening processes. By investing in polyurethane high frequency sieves, companies can expect to see increased productivity, higher quality end products, and a more sustainable operation.