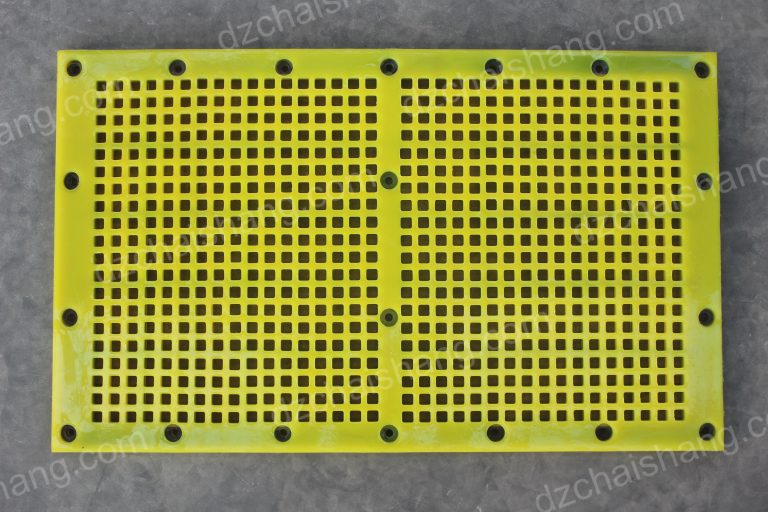

Manufacturer polyurethane wire panel Ore

Benefits of Using polyurethane Wire Panels in Manufacturing Operations Polyurethane wire panels have become increasingly popular in manufacturing operations due to their…

Benefits of Using polyurethane Wire Panels in Manufacturing Operations

Polyurethane wire panels have become increasingly popular in manufacturing operations due to their numerous benefits. These panels are made from a durable and versatile material that offers a wide range of advantages for manufacturers looking to improve their processes and efficiency. In this article, we will explore some of the key benefits of using polyurethane wire panels in manufacturing operations. One of the primary benefits of polyurethane wire panels is their durability. These panels are designed to withstand heavy use and harsh conditions, making them ideal for use in manufacturing environments where equipment is subject to wear and tear. Polyurethane is a tough material that can resist abrasion, impact, and chemicals, ensuring that the panels will last for a long time without needing to be replaced. In addition to their durability, polyurethane wire panels are also highly versatile. These panels can be customized to fit a wide range of applications, making them suitable for use in various manufacturing processes. Whether you need panels for conveyor systems, machinery guards, or noise barriers, polyurethane wire panels can be tailored to meet your specific requirements. Another key benefit of using polyurethane wire panels in manufacturing operations is their ease of installation. These panels are lightweight and easy to handle, making them simple to install and reconfigure as needed. This can help manufacturers save time and money on installation costs, as well as reduce downtime during the installation process. Polyurethane wire panels are also easy to maintain, requiring minimal upkeep to keep them in good condition. Unlike other materials that may require regular cleaning or repairs, polyurethane wire panels can be easily wiped down with a damp cloth to remove dirt and debris. This can help manufacturers save time and money on maintenance costs, as well as ensure that their equipment remains in optimal working condition.