High Quality vibrator Rubber tension panel Aggregate

Benefits of Using High Quality Vibrator Rubber Tension Panels in Aggregate Processing Aggregate processing is a crucial step in the construction industry,…

Benefits of Using High Quality Vibrator Rubber Tension Panels in Aggregate Processing

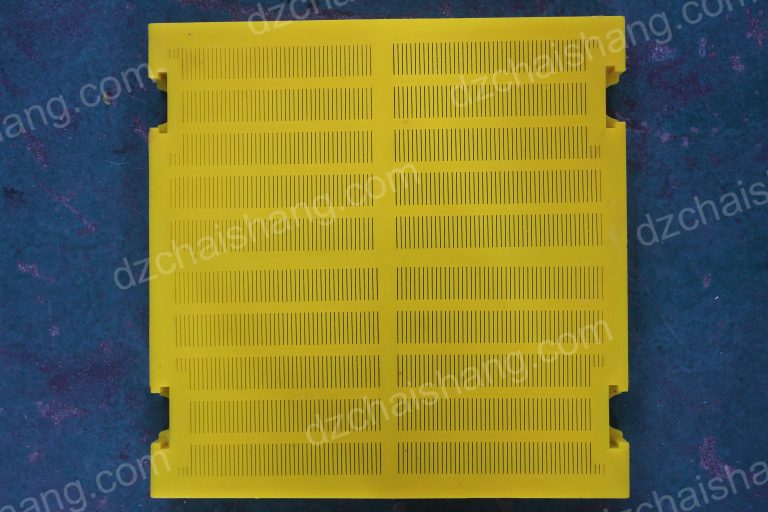

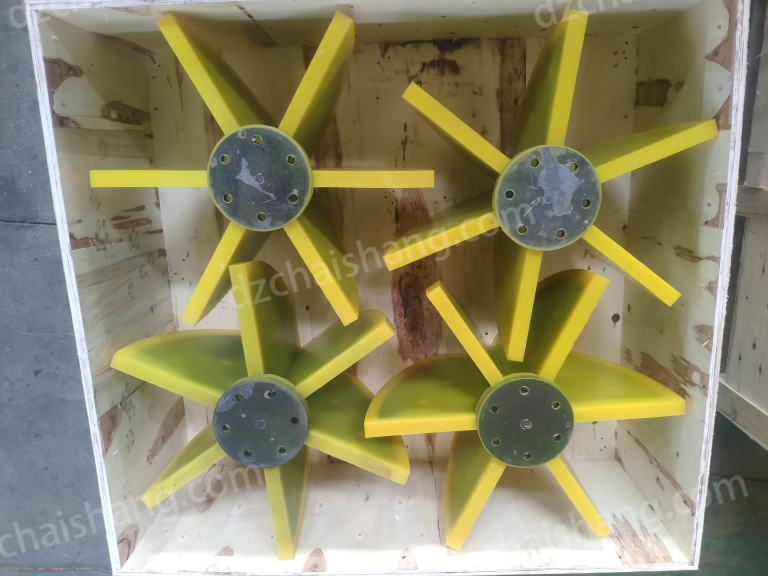

Aggregate processing is a crucial step in the construction industry, as it involves the crushing and screening of raw materials to create the base materials used in building roads, bridges, and other infrastructure projects. One key component of aggregate processing equipment is the vibrator rubber tension panel, which plays a vital role in ensuring the efficiency and effectiveness of the screening process. High-quality vibrator rubber tension panels are designed to withstand the rigorous demands of aggregate processing. These panels are made from durable rubber materials that are resistant to wear and tear, ensuring long-lasting performance even in the most challenging operating conditions. The use of high-quality rubber tension panels in aggregate processing equipment can result in significant benefits for operators and contractors alike. One of the primary benefits of using high-quality vibrator rubber tension panels is their ability to improve screening efficiency. These panels are designed to provide optimal tension and support to the screening media, ensuring that it remains taut and in place during operation. This helps to prevent material blinding and clogging, allowing for more efficient and consistent screening of aggregate materials. In addition to improving screening efficiency, high-quality vibrator rubber tension panels also help to reduce downtime and maintenance costs. The durable rubber materials used in these panels are resistant to abrasion and impact, reducing the likelihood of premature wear and tear. This means that operators can enjoy longer intervals between maintenance and replacement, resulting in increased uptime and productivity. Furthermore, high-quality vibrator rubber tension panels can also help to improve the overall quality of the screened aggregate materials. By providing consistent tension and support to the screening media, these panels help to ensure that the materials are properly sized and graded. This can result in higher-quality end products that meet the specifications and requirements of construction projects, leading to improved customer satisfaction and project outcomes. Another key benefit of using high-quality vibrator rubber tension panels is their versatility and compatibility with a wide range of screening equipment. These panels can be easily installed and integrated into various types of vibrating screens and screening machines, making them a cost-effective and practical solution for aggregate processing operations of all sizes. In conclusion, the use of high-quality vibrator rubber tension panels in aggregate processing equipment offers a range of benefits for operators and contractors. From improving screening efficiency and reducing downtime to enhancing the quality of screened materials and increasing equipment versatility, these panels play a crucial role in optimizing the performance of aggregate processing operations. By investing in high-quality rubber tension panels, operators can ensure that their screening equipment operates at peak performance, leading to improved productivity, profitability, and overall project success.How to Choose the Best High Quality Vibrator Rubber Tension Panels for Aggregate Equipment

When it comes to aggregate equipment, one of the key components that play a crucial role in the overall performance is the vibrator rubber tension panel. These panels are designed to provide the necessary tension and support to the vibrating screens, ensuring efficient and effective screening of aggregates. However, not all vibrator rubber tension panels are created equal, and choosing the best quality panels is essential for maximizing the productivity and longevity of your equipment. One of the most important factors to consider when selecting vibrator rubber tension panels is the quality of the rubber material used. High-quality rubber panels are made from premium-grade rubber compounds that are specifically formulated to withstand the harsh conditions of aggregate screening. These panels are resistant to abrasion, tearing, and corrosion, ensuring long-lasting performance and durability. In addition to the quality of the rubber material, the design and construction of the tension panels also play a significant role in their performance. Look for panels that are precision-engineered to provide optimal tension and support to the vibrating screens. Panels with reinforced edges and strategically placed tension holes are more likely to provide a secure and stable fit, reducing the risk of premature wear and tear.

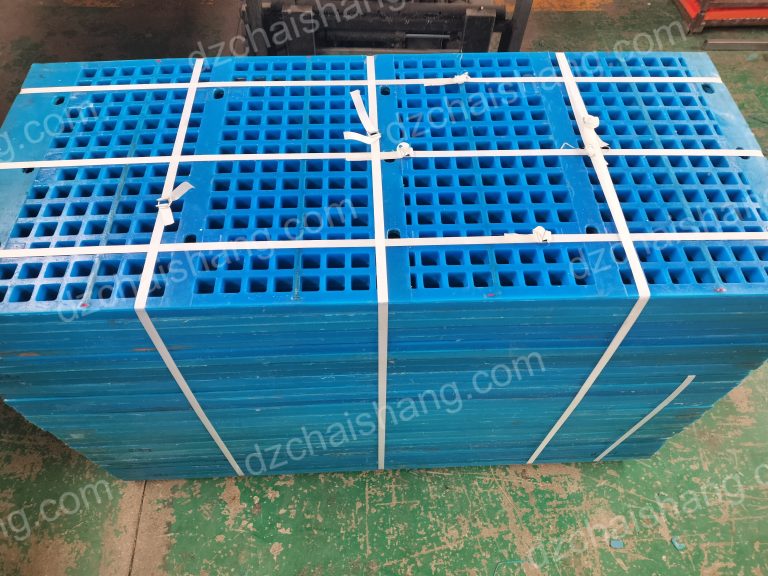

Another important consideration when choosing vibrator rubber tension panels is the size and dimensions of the panels. It is essential to select panels that are compatible with the specific make and model of your vibrating screens. Panels that are too small or too large may not provide the necessary tension and support, leading to inefficient screening and potential damage to the equipment.

When shopping for vibrator rubber tension panels, it is also important to consider the reputation and reliability of the manufacturer. Look for reputable suppliers that have a proven track record of producing high-quality panels for aggregate equipment. Manufacturers that offer warranties and guarantees on their products are more likely to stand behind the quality and performance of their tension panels.

In addition to the quality of the panels, it is also important to consider the cost-effectiveness of the product. While it may be tempting to opt for cheaper panels to save on costs, investing in high-quality tension panels can actually save you money in the long run. Quality panels are less likely to require frequent replacements or repairs, reducing downtime and maintenance costs.

In addition to the quality of the rubber material, the design and construction of the tension panels also play a significant role in their performance. Look for panels that are precision-engineered to provide optimal tension and support to the vibrating screens. Panels with reinforced edges and strategically placed tension holes are more likely to provide a secure and stable fit, reducing the risk of premature wear and tear.

Another important consideration when choosing vibrator rubber tension panels is the size and dimensions of the panels. It is essential to select panels that are compatible with the specific make and model of your vibrating screens. Panels that are too small or too large may not provide the necessary tension and support, leading to inefficient screening and potential damage to the equipment.

When shopping for vibrator rubber tension panels, it is also important to consider the reputation and reliability of the manufacturer. Look for reputable suppliers that have a proven track record of producing high-quality panels for aggregate equipment. Manufacturers that offer warranties and guarantees on their products are more likely to stand behind the quality and performance of their tension panels.

In addition to the quality of the panels, it is also important to consider the cost-effectiveness of the product. While it may be tempting to opt for cheaper panels to save on costs, investing in high-quality tension panels can actually save you money in the long run. Quality panels are less likely to require frequent replacements or repairs, reducing downtime and maintenance costs.