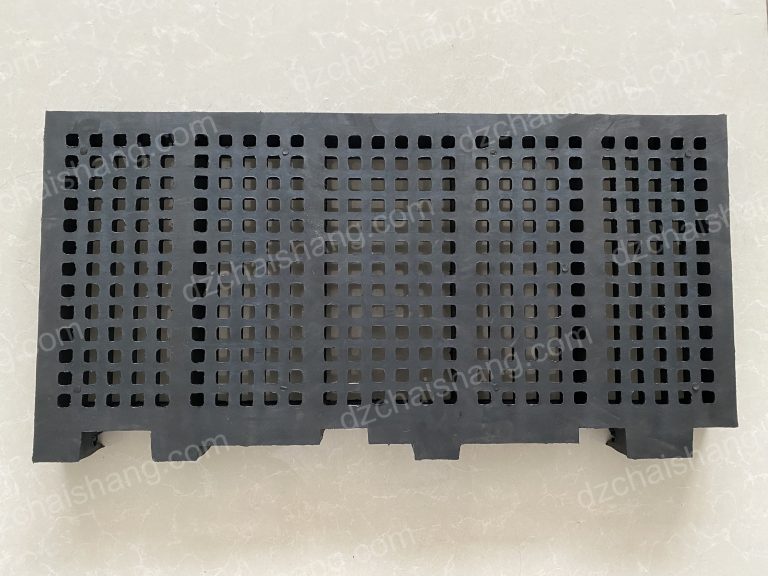

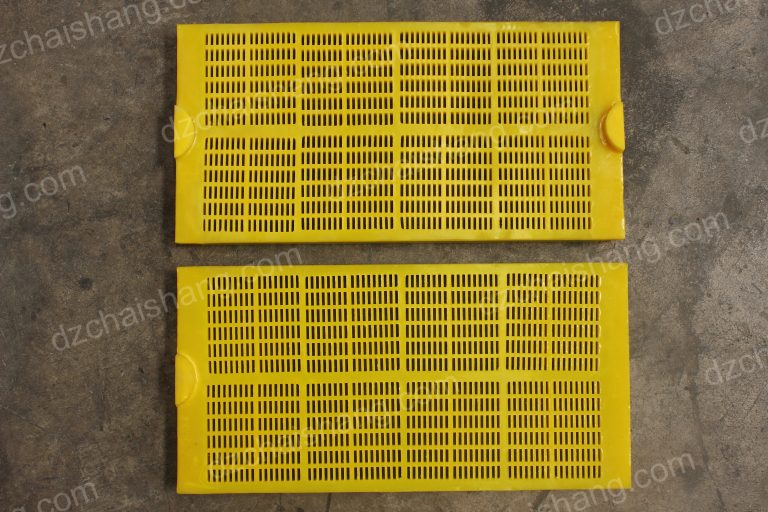

direct sale Mining Rubber secondary

The Benefits of Using Rubber Secondary in Direct Sale mining If you’re in the mining industry, you know that safety is paramount….

The Benefits of Using Rubber Secondary in Direct Sale mining

If you’re in the mining industry, you know that safety is paramount. That’s why it’s important to use the right materials for the job. Rubber secondary containment systems are becoming increasingly popular in direct sale mining operations, and for good reason. Here are some of the benefits of using rubber secondary containment in direct sale mining. 1. Durability: Rubber secondary containment systems are incredibly durable and can withstand the harsh conditions of mining operations. They’re designed to be resistant to abrasion, corrosion, and extreme temperatures, so you can be sure that your system will last for years to come.How to Maximize Efficiency with Rubber Secondary in Direct Sale Mining

If you’re in the mining industry, you know that rubber secondary is an essential part of the process. It’s used to protect the equipment and ensure that it runs smoothly and efficiently. But how can you maximize efficiency when it comes to rubber secondary in direct sale mining? Here are a few tips to help you out. 1. Invest in Quality Rubber Secondary: The quality of the rubber secondary you use will have a direct impact on the efficiency of your mining operations. Investing in high-quality rubber secondary will ensure that your equipment is well-protected and running at peak performance. 2. Monitor Wear and Tear: Regularly monitoring the wear and tear of your rubber secondary is essential for maximizing efficiency. If you notice any signs of wear or damage, replace the rubber secondary immediately to avoid any potential problems. 3. Use the Right Tools: Using the right tools for the job is essential for maximizing efficiency. Make sure you have the right tools for the job, such as the right size and type of rubber secondary, to ensure that your mining operations are running as efficiently as possible. 4. Regularly Inspect and Maintain: Regularly inspecting and maintaining your rubber secondary is essential for maximizing efficiency. Make sure to inspect your rubber secondary regularly and replace any worn or damaged parts as soon as possible. By following these tips, you can maximize efficiency with rubber secondary in direct sale mining. Investing in quality rubber secondary, monitoring wear and tear, using the right tools, and regularly inspecting and maintaining your rubber secondary are all essential for maximizing efficiency. With these tips, you can ensure that your mining operations are running as efficiently as possible.