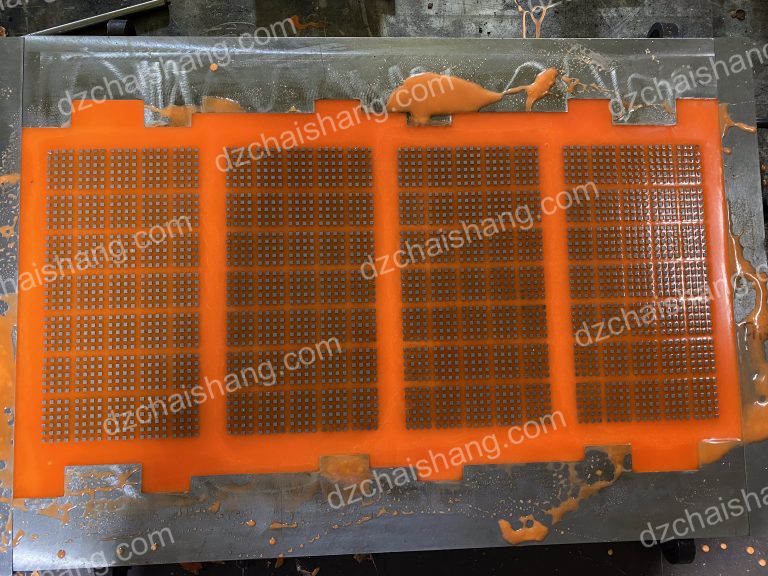

Vibrating PU Mesh,Polyurethane Edged Screen Panel

Benefits of Using Vibrating PU mesh in Screening Applications Vibrating PU mesh, also known as polyurethane edged screen panel, is a popular…

Benefits of Using Vibrating PU mesh in Screening Applications

Vibrating PU mesh, also known as polyurethane edged screen panel, is a popular choice for screening applications in various industries. This innovative material offers a range of benefits that make it a superior option for separating and classifying materials. In this article, we will explore the advantages of using vibrating PU mesh in screening applications. One of the key benefits of vibrating PU mesh is its durability. Polyurethane is a strong and resilient material that can withstand the rigors of screening operations. Unlike traditional wire mesh screens, PU mesh is less prone to wear and tear, resulting in longer-lasting screens that require less frequent replacement. This durability translates to cost savings for businesses, as they can reduce maintenance and downtime associated with screen replacements. In addition to its durability, vibrating PU mesh offers excellent abrasion resistance. This is particularly important in industries where materials are abrasive or corrosive, as traditional screens may wear out quickly when exposed to harsh conditions. PU mesh, on the other hand, is designed to resist abrasion and maintain its integrity even in challenging environments. This makes it an ideal choice for screening applications in mining, construction, and other industries where materials can be abrasive. Another advantage of vibrating PU mesh is its flexibility. Polyurethane is a versatile material that can be molded into various shapes and sizes to meet specific screening requirements. This flexibility allows for customization of screen panels to fit different screening equipment and applications. Whether you need a fine mesh for precise classification or a larger opening for coarse screening, PU mesh can be tailored to your needs. Furthermore, vibrating PU mesh offers superior screening performance. The material is designed to provide efficient and effective screening of materials, ensuring accurate separation and classification. Its high tensile strength and elasticity allow for optimal vibration transmission, resulting in improved screening efficiency and throughput. This means that businesses can achieve higher productivity and throughput with PU mesh screens compared to traditional options. Additionally, vibrating PU mesh is easy to install and maintain. The lightweight nature of polyurethane makes it easy to handle and install on screening equipment. Its modular design allows for quick and simple replacement of individual screen panels, reducing downtime and increasing operational efficiency. Maintenance of PU mesh screens is also straightforward, as the material is easy to clean and resistant to clogging. In conclusion, vibrating PU mesh offers a range of benefits that make it a superior choice for screening applications. Its durability, abrasion resistance, flexibility, and superior screening performance make it an ideal option for industries that require efficient and reliable screening solutions. With its ease of installation and maintenance, PU mesh screens provide businesses with a cost-effective and efficient screening solution. Consider using vibrating PU mesh in your screening applications to experience the advantages it has to offer.How Polyurethane Edged Screen Panels Improve Screen Efficiency

Polyurethane edged screen panels are a popular choice for many industries due to their durability, flexibility, and efficiency. These panels are designed to improve screen efficiency by providing a more effective screening surface that can withstand the rigors of heavy-duty applications. One type of polyurethane edged screen panel that has gained popularity in recent years is the vibrating PU mesh panel. The vibrating PU mesh panel is made from high-quality polyurethane material that is designed to withstand the wear and tear of constant vibration and movement. This type of panel is ideal for applications where high-frequency vibrations are required to separate materials efficiently. The polyurethane material used in these panels is highly resistant to abrasion, chemicals, and temperature fluctuations, making it a durable and long-lasting option for screening operations. One of the key benefits of using vibrating PU mesh panels is their ability to improve screen efficiency. The polyurethane material used in these panels is designed to provide a smooth and consistent screening surface that allows for more accurate separation of materials. This results in higher throughput rates and improved product quality, making vibrating PU mesh panels an ideal choice for industries that require precise screening operations. In addition to improving screen efficiency, vibrating PU mesh panels also offer other advantages. These panels are lightweight and easy to install, making them a cost-effective option for businesses looking to upgrade their screening equipment. The flexibility of the polyurethane material allows for easy customization of panel sizes and shapes, making it easy to adapt to different screening applications.Comparing Vibrating PU Mesh to Traditional Screen Panel Materials

When it comes to choosing the right screen panel material for vibrating screens, there are several options available on the market. One of the newer materials that has gained popularity in recent years is vibrating PU mesh, also known as polyurethane edged screen panel. This material offers several advantages over traditional screen panel materials such as rubber and steel. One of the key benefits of vibrating PU mesh is its durability. Polyurethane is a highly resilient material that can withstand the rigors of constant vibration and abrasion. This means that vibrating PU mesh panels are less likely to wear out or break compared to traditional screen panel materials. This durability translates to cost savings for operators, as they will not have to replace the panels as frequently. In addition to its durability, vibrating PU mesh also offers superior screening performance. The fine mesh design of Polyurethane Panels allows for more efficient screening of materials, resulting in higher throughput and better separation of particles. This can lead to increased productivity and improved product quality for operators. Another advantage of vibrating PU mesh is its versatility. Polyurethane panels can be custom-made to fit any screen deck size or configuration, making them suitable for a wide range of applications. Whether you are screening fine particles or heavy aggregates, vibrating PU mesh panels can be tailored to meet your specific needs. Furthermore, vibrating PU mesh is easy to install and maintain. The lightweight nature of polyurethane panels makes them easy to handle and install, reducing downtime during screen panel replacement. Additionally, polyurethane is resistant to corrosion and chemical damage, making it a low-maintenance option for operators. When compared to traditional screen panel materials such as rubber and steel, vibrating PU mesh stands out as a superior choice for vibrating screens. Rubber panels are prone to wear and tear, while steel panels can be heavy and difficult to handle. Vibrating PU mesh offers the best of both worlds – durability and performance – making it an ideal option for operators looking to maximize their screening efficiency. In conclusion, vibrating PU mesh, also known as polyurethane edged screen panel, is a superior choice for vibrating screens compared to traditional screen panel materials. Its durability, screening performance, versatility, and ease of installation and maintenance make it a top choice for operators looking to optimize their screening operations. By choosing vibrating PU mesh panels, operators can expect increased productivity, improved product quality, and cost savings in the long run.