high quality vibrating polyurethane screen,high quality polyurethane mining screens

Maximizing Efficiency with High Quality Vibrating polyurethane screens Maximizing efficiency in mining operations is a critical aspect that every industry player strives…

Maximizing Efficiency with High Quality Vibrating polyurethane screens

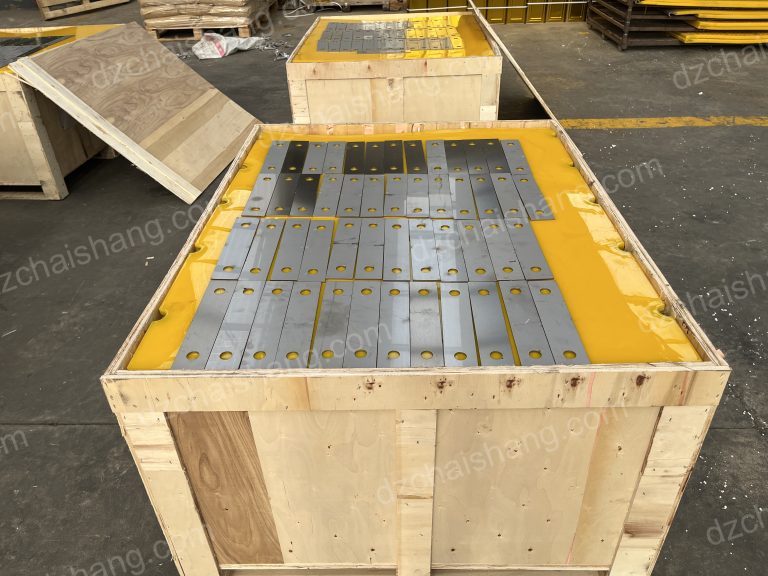

Maximizing efficiency in mining operations is a critical aspect that every industry player strives to achieve. One of the ways to realize this goal is by using high-quality vibrating polyurethane screens. These screens are renowned for their durability, efficiency, and versatility, making them an essential tool in the mining industry. High-quality vibrating polyurethane screens are designed to offer superior performance in screening and separation of minerals and aggregates. They are made from polyurethane, a material known for its exceptional resistance to wear and tear, abrasion, and damage from oils and solvents. This makes them ideal for use in harsh mining environments where durability and longevity are paramount. The efficiency of these screens is further enhanced by their vibrating mechanism. This feature allows for the effective separation of materials based on size, a critical aspect in mining operations. The vibration facilitates the movement of materials across the screen, ensuring that smaller particles fall through the screen’s holes while larger ones remain on top. This process significantly improves the efficiency of mineral and aggregate separation, leading to increased productivity. Moreover, high-quality polyurethane mining screens are designed to handle a wide range of materials. Whether dealing with coarse or fine materials, wet or dry, these screens can effectively handle the task. Their versatility is further demonstrated in their ability to be used in various types of mining equipment, including trommels, dewatering screens, and flip-flow screens. This adaptability makes them a valuable asset in any mining operation. The benefits of using high-quality vibrating polyurethane screens extend beyond their performance and versatility. They also contribute to cost savings in the long run. Given their durability, these screens require less frequent replacement compared to screens made from other materials. This translates to reduced downtime and maintenance costs, further enhancing the efficiency of mining operations. In addition, the use of high-quality polyurethane mining screens contributes to environmental sustainability. Polyurethane is a recyclable material, meaning that once the screens have reached the end of their useful life, they can be recycled into new products. This not only reduces waste but also lessens the demand for raw materials, contributing to sustainable mining practices.Exploring the Durability of high quality polyurethane mining screens

In the mining industry, the importance of using high-quality equipment cannot be overstated. One such essential piece of equipment is the vibrating screen, which plays a crucial role in the separation of materials based on their size. Among the various types of screens available, the high-quality vibrating polyurethane screen and high-quality polyurethane mining screens have emerged as the preferred choice for many mining operations due to their superior durability and performance. Polyurethane, a versatile elastomer, is known for its exceptional resistance to wear, tear, and extreme weather conditions. These properties make it an ideal material for mining screens. The high-quality polyurethane mining screens are designed to withstand the harsh conditions of the mining environment, including abrasive materials, high temperatures, and corrosive elements. The durability of these screens is further enhanced by their unique design. The high-quality vibrating polyurethane screen, for instance, features a multi-layer design that not only increases its lifespan but also improves its efficiency. The top layer is designed to absorb the impact of the material, thereby reducing wear and tear. The subsequent layers are designed to facilitate effective separation of materials, ensuring optimal performance at all times.

The high-quality polyurethane mining screens, on the other hand, are designed with a self-cleaning mechanism. This feature ensures that the screens remain unblocked, thereby maintaining their efficiency. The self-cleaning mechanism also reduces the need for manual cleaning, saving time and resources.

In addition to their durability and efficiency, these screens are also known for their versatility. They can be used for various applications, including dewatering, desliming, and scalping. This versatility makes them a cost-effective solution for mining operations, as they eliminate the need for multiple screens.

Moreover, the high-quality vibrating polyurethane screen and high-quality polyurethane mining screens are easy to install and maintain. They are designed to fit into existing systems seamlessly, reducing downtime during installation. Their maintenance requirements are also minimal, further enhancing their cost-effectiveness.

Despite their numerous advantages, it is important to note that the performance of these screens is largely dependent on their quality. Therefore, it is crucial to source these screens from reputable manufacturers who adhere to strict quality control measures. This ensures that the screens are not only durable but also reliable, providing consistent performance over their lifespan.

In conclusion, the high-quality vibrating polyurethane screen and high-quality polyurethane mining screens are a testament to the advancements in mining technology. Their superior durability, efficiency, and versatility make them an invaluable asset for any mining operation. By investing in these screens, mining companies can not only enhance their operations but also realize significant cost savings in the long run. Therefore, it is safe to say that these screens are not just a choice, but a necessity for any mining operation that prioritizes efficiency and cost-effectiveness.

The durability of these screens is further enhanced by their unique design. The high-quality vibrating polyurethane screen, for instance, features a multi-layer design that not only increases its lifespan but also improves its efficiency. The top layer is designed to absorb the impact of the material, thereby reducing wear and tear. The subsequent layers are designed to facilitate effective separation of materials, ensuring optimal performance at all times.

The high-quality polyurethane mining screens, on the other hand, are designed with a self-cleaning mechanism. This feature ensures that the screens remain unblocked, thereby maintaining their efficiency. The self-cleaning mechanism also reduces the need for manual cleaning, saving time and resources.

In addition to their durability and efficiency, these screens are also known for their versatility. They can be used for various applications, including dewatering, desliming, and scalping. This versatility makes them a cost-effective solution for mining operations, as they eliminate the need for multiple screens.

Moreover, the high-quality vibrating polyurethane screen and high-quality polyurethane mining screens are easy to install and maintain. They are designed to fit into existing systems seamlessly, reducing downtime during installation. Their maintenance requirements are also minimal, further enhancing their cost-effectiveness.

Despite their numerous advantages, it is important to note that the performance of these screens is largely dependent on their quality. Therefore, it is crucial to source these screens from reputable manufacturers who adhere to strict quality control measures. This ensures that the screens are not only durable but also reliable, providing consistent performance over their lifespan.

In conclusion, the high-quality vibrating polyurethane screen and high-quality polyurethane mining screens are a testament to the advancements in mining technology. Their superior durability, efficiency, and versatility make them an invaluable asset for any mining operation. By investing in these screens, mining companies can not only enhance their operations but also realize significant cost savings in the long run. Therefore, it is safe to say that these screens are not just a choice, but a necessity for any mining operation that prioritizes efficiency and cost-effectiveness.