vibrator sieve plate,screen mesh,dewatering sieve

Exploring the Functionality and Applications of Vibrator Sieve Plates Vibrator sieve plates, screen mesh, and dewatering sieves are integral components in various…

Exploring the Functionality and Applications of Vibrator Sieve Plates

Vibrator sieve plates, screen mesh, and dewatering sieves are integral components in various industrial processes. These tools play a crucial role in the separation, classification, and dewatering of materials, contributing significantly to the efficiency and effectiveness of these processes. Understanding their functionality and applications can provide valuable insights into their importance in different industries.Understanding the Role of Screen Mesh and Dewatering Sieve in Material Separation

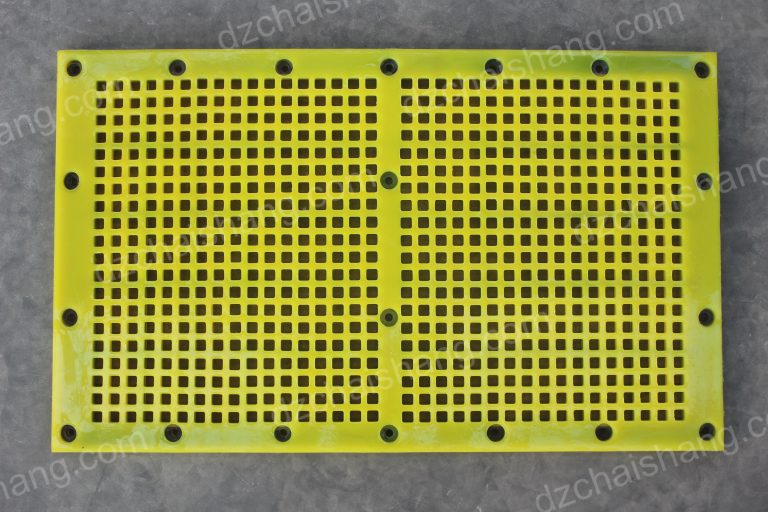

In the realm of material separation, two key components play a pivotal role: the screen mesh and the dewatering sieve. These elements, often overlooked, are integral to the process of separating materials of different sizes and densities. They are particularly crucial in industries such as mining, construction, and waste management, where the separation of materials is a routine task. The screen mesh, also known as a vibrator sieve plate, is a metal grid with uniformly sized openings. It is designed to filter materials by size, allowing smaller particles to pass through while retaining larger ones. The size of the openings in the screen mesh can be adjusted according to the specific requirements of the separation process. The screen mesh is typically made of robust materials such as stainless steel or polyurethane to withstand the rigors of industrial use. The screen mesh’s effectiveness is not solely dependent on the size of its openings. The shape of the openings also plays a significant role. For instance, square openings are ideal for separating materials of similar sizes, while slotted openings are better suited for separating elongated particles. The choice of opening shape is, therefore, dependent on the nature of the materials being separated. On the other hand, the dewatering sieve, also known as a dewatering screen, is used to remove water from wet materials. It is an essential tool in industries where materials need to be dried before further processing. The dewatering sieve works by applying a high-frequency vibration to the wet material. This vibration forces the water to separate from the material and pass through the sieve, leaving behind the dried material.

The dewatering sieve is not a one-size-fits-all solution. Like the screen mesh, it can be customized to suit specific industrial needs. Factors such as the size and nature of the material, the amount of water to be removed, and the desired dryness level of the material all influence the design of the dewatering sieve.

The combination of the screen mesh and the dewatering sieve provides a comprehensive solution for material separation. The screen mesh first separates the material based on size, after which the dewatering sieve removes any excess water. This two-step process ensures that the separated material is not only of the right size but also sufficiently dry for further processing.

In conclusion, the screen mesh and the dewatering sieve are indispensable tools in the material separation process. They offer a reliable and efficient means of separating materials based on size and moisture content. By understanding their role and functionality, industries can optimize their material separation processes, leading to improved efficiency and productivity. Therefore, it is essential for industry professionals to appreciate the importance of these tools and consider their specific requirements when selecting a screen mesh or a dewatering sieve.

On the other hand, the dewatering sieve, also known as a dewatering screen, is used to remove water from wet materials. It is an essential tool in industries where materials need to be dried before further processing. The dewatering sieve works by applying a high-frequency vibration to the wet material. This vibration forces the water to separate from the material and pass through the sieve, leaving behind the dried material.

The dewatering sieve is not a one-size-fits-all solution. Like the screen mesh, it can be customized to suit specific industrial needs. Factors such as the size and nature of the material, the amount of water to be removed, and the desired dryness level of the material all influence the design of the dewatering sieve.

The combination of the screen mesh and the dewatering sieve provides a comprehensive solution for material separation. The screen mesh first separates the material based on size, after which the dewatering sieve removes any excess water. This two-step process ensures that the separated material is not only of the right size but also sufficiently dry for further processing.

In conclusion, the screen mesh and the dewatering sieve are indispensable tools in the material separation process. They offer a reliable and efficient means of separating materials based on size and moisture content. By understanding their role and functionality, industries can optimize their material separation processes, leading to improved efficiency and productivity. Therefore, it is essential for industry professionals to appreciate the importance of these tools and consider their specific requirements when selecting a screen mesh or a dewatering sieve.