vibrating screen panel,PU coated wire sieve panel,urethane mesh sieve

Maximizing Efficiency with vibrating screen Panel and urethane mesh sieve Maximizing efficiency in the mining and aggregate industries is a constant challenge….

Maximizing Efficiency with vibrating screen Panel and urethane mesh sieve

Maximizing efficiency in the mining and aggregate industries is a constant challenge. One of the key areas where efficiency can be improved is in the screening process. The use of a vibrating screen panel, PU coated wire sieve panel, and urethane mesh sieve can significantly enhance the screening process, leading to increased productivity and cost savings. A vibrating screen panel is a type of screening equipment that uses vibration to separate materials of different sizes. It consists of a screen deck, screen box, vibrating motor, eccentric block, rubber spring, and coupling-adopt motor with vibration exciter that work together to efficiently classify and separate the materials according to the particle size. The vibrating screen panel is designed to handle a wide range of materials, from fine powders to large rocks, making it a versatile tool in the mining and aggregate industries.

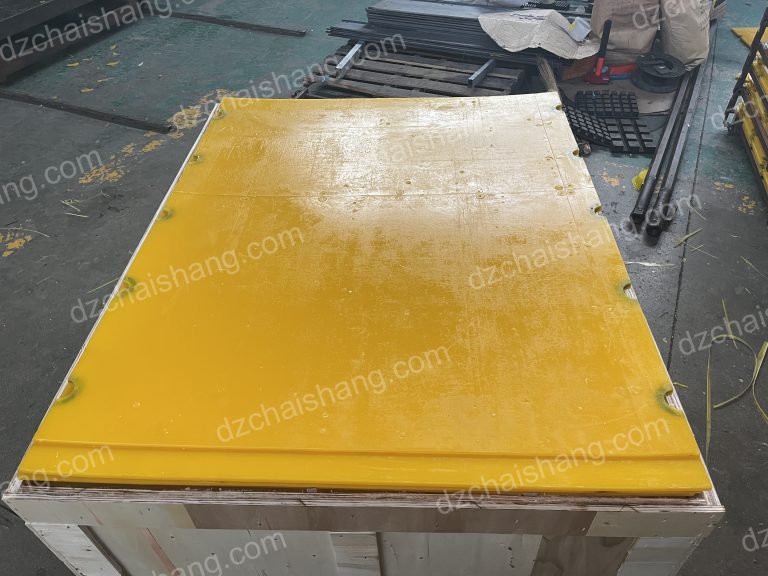

The PU coated wire sieve panel is another innovative solution that can enhance the screening process. PU, or polyurethane, is a type of plastic that is known for its exceptional durability and resistance to wear, tear, and abrasion. When used to coat a wire sieve panel, it creates a highly durable and long-lasting screen that can withstand the rigors of the screening process. The PU coating also provides a smooth surface that allows materials to slide easily over the screen, reducing the likelihood of clogging and improving the efficiency of the screening process.