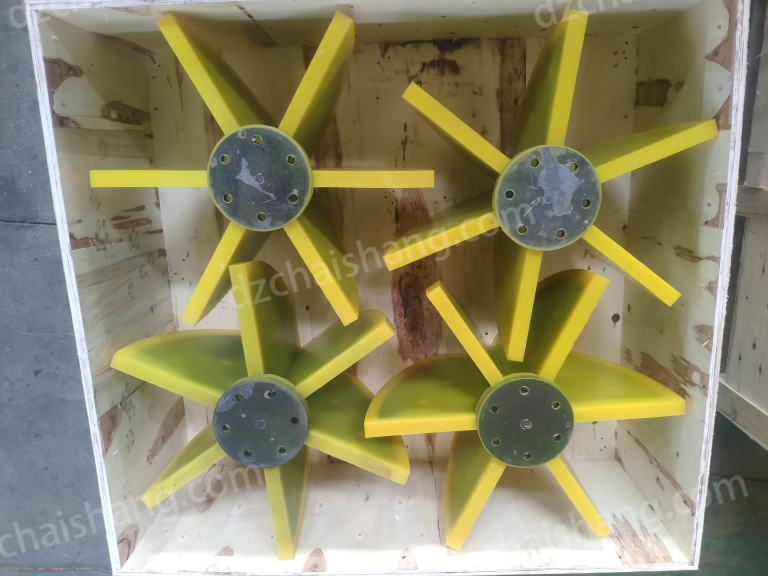

vibrating Rubber high frequency Deck Made to order

Benefits of Using a Vibrating Rubber high frequency Deck for Customized Applications Vibrating rubber high frequency decks are a versatile and customizable…

Benefits of Using a Vibrating Rubber high frequency Deck for Customized Applications

Vibrating rubber high frequency decks are a versatile and customizable solution for a wide range of applications. These decks are designed to efficiently separate materials based on size, shape, and density, making them ideal for industries such as mining, construction, and recycling. By incorporating high frequency vibrations into the deck, these systems can achieve higher throughput rates and improved separation efficiency compared to traditional screening methods. One of the key benefits of using a vibrating rubber high frequency deck is its ability to be tailored to specific requirements. These decks can be customized in terms of size, shape, and material composition to meet the unique needs of each application. This level of customization allows for greater flexibility and precision in the screening process, resulting in higher quality end products and increased productivity. In addition to customization, vibrating rubber high frequency decks offer several other advantages. The high frequency vibrations generated by these decks help to prevent material blinding and pegging, ensuring a consistent and efficient screening process. This results in reduced downtime and maintenance costs, as well as improved overall performance.