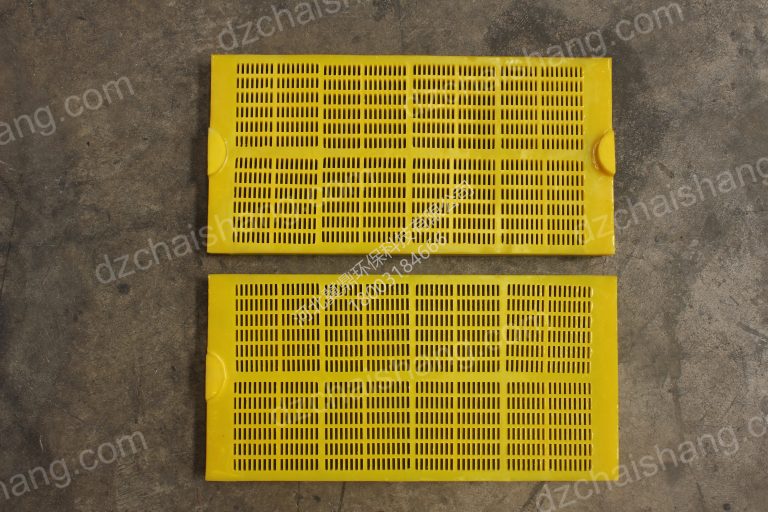

vibrating polyurethane wire screen Customized

Benefits of Using Vibrating polyurethane wire screens in Industrial Applications Vibrating polyurethane wire screens are a versatile and efficient solution for a…

Benefits of Using Vibrating polyurethane wire screens in Industrial Applications

Vibrating polyurethane wire screens are a versatile and efficient solution for a wide range of industrial applications. These screens are made from high-quality polyurethane material that is durable, flexible, and resistant to abrasion, making them ideal for use in demanding environments. One of the key benefits of using vibrating polyurethane wire screens is their ability to effectively screen and separate materials of different sizes and shapes. The flexibility of polyurethane material allows the wire screens to vibrate at high frequencies, which helps to efficiently separate particles and prevent blinding. This results in a more efficient screening process and higher throughput rates, ultimately improving the overall productivity of industrial operations. Additionally, the high tensile strength of polyurethane wire screens ensures long-lasting performance, reducing the need for frequent replacements and maintenance. Another advantage of vibrating polyurethane wire screens is their customization options. These screens can be tailored to meet specific requirements, such as aperture size, wire diameter, and screen panel dimensions. This level of customization allows for greater control over the screening process, ensuring optimal performance and efficiency. Whether screening fine particles or heavy-duty materials, vibrating polyurethane wire screens can be customized to suit the unique needs of any industrial application.

In addition to their durability and customization options, vibrating polyurethane wire screens offer superior wear resistance. The polyurethane material is highly resistant to abrasion, impact, and chemicals, making it ideal for use in harsh environments. This resistance to wear and tear ensures that the wire screens maintain their performance and longevity, even in the most demanding conditions. As a result, industrial operations can rely on vibrating polyurethane wire screens for consistent and reliable screening performance.

Another advantage of vibrating polyurethane wire screens is their customization options. These screens can be tailored to meet specific requirements, such as aperture size, wire diameter, and screen panel dimensions. This level of customization allows for greater control over the screening process, ensuring optimal performance and efficiency. Whether screening fine particles or heavy-duty materials, vibrating polyurethane wire screens can be customized to suit the unique needs of any industrial application.

In addition to their durability and customization options, vibrating polyurethane wire screens offer superior wear resistance. The polyurethane material is highly resistant to abrasion, impact, and chemicals, making it ideal for use in harsh environments. This resistance to wear and tear ensures that the wire screens maintain their performance and longevity, even in the most demanding conditions. As a result, industrial operations can rely on vibrating polyurethane wire screens for consistent and reliable screening performance.