polyurethane screen plate like a polyurethane screen sieve despite definition

The Benefits of polyurethane screen plate for Sieving and Separating Materials Polyurethane screen plates are an increasingly popular choice for sieving and…

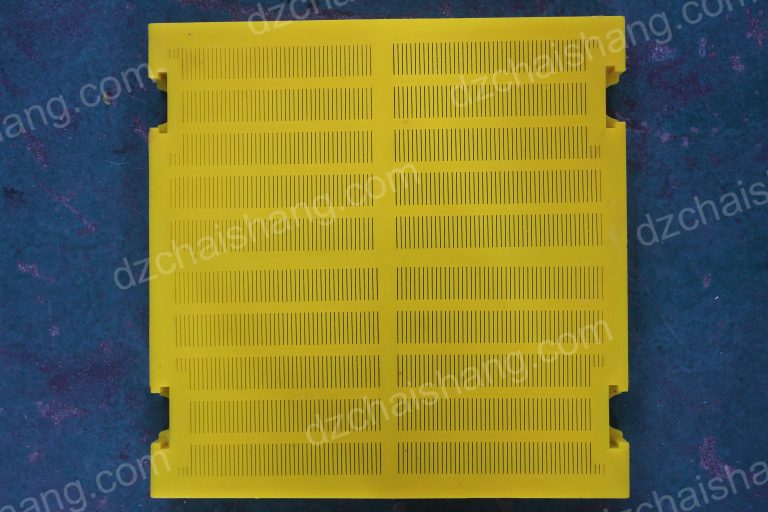

The Benefits of polyurethane screen plate for Sieving and Separating Materials

Polyurethane screen plates are an increasingly popular choice for sieving and separating materials. This is due to the many benefits they offer over traditional metal screens. First, polyurethane screen plates are much more durable than metal screens. They are resistant to corrosion, abrasion, and wear, making them ideal for use in harsh environments. Additionally, they are flexible and can be easily cut to fit any size or shape. This makes them ideal for use in a variety of applications. Finally, polyurethane screen plates are much more cost-effective than metal screens. They are much cheaper to purchase and maintain, resulting in lower overall costs. Additionally, they are much easier to install and replace, reducing downtime and labor costs.

Overall, polyurethane screen plates offer many advantages over traditional metal screens. They are more durable, efficient, safe, and cost-effective, making them an ideal choice for sieving and separating materials.

Finally, polyurethane screen plates are much more cost-effective than metal screens. They are much cheaper to purchase and maintain, resulting in lower overall costs. Additionally, they are much easier to install and replace, reducing downtime and labor costs.

Overall, polyurethane screen plates offer many advantages over traditional metal screens. They are more durable, efficient, safe, and cost-effective, making them an ideal choice for sieving and separating materials.