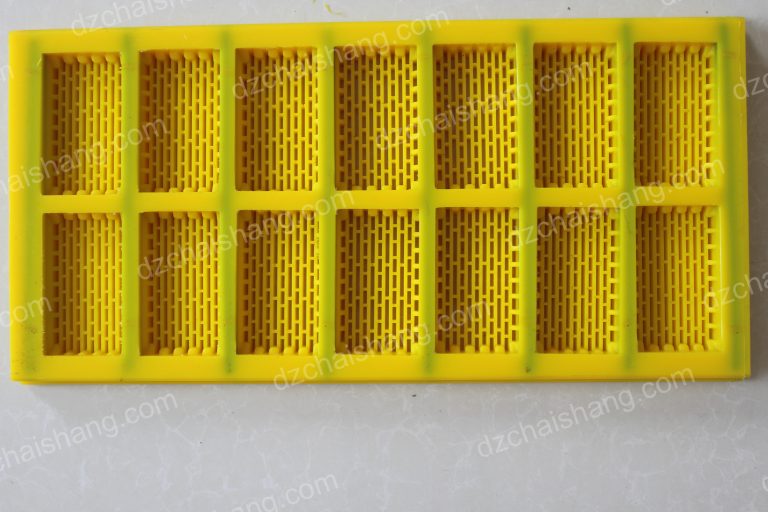

Cheap Rubber trommel Media Mining,wholesaler vibrating fine Rubber sieve

Effective Strategies for Using Cheap Rubber Trommel Media in mining Operations Effective Strategies for Using Cheap Rubber Trommel Media in Mining Operations…

Effective Strategies for Using Cheap Rubber Trommel Media in mining Operations

Effective Strategies for Using Cheap Rubber Trommel Media in Mining Operations Mining operations rely heavily on efficient processes to extract valuable materials from the earth. Among the many tools and equipment used in mining, trommel screens play a crucial role in separating materials of different sizes. While the quality of trommel media can significantly impact performance, there are effective strategies for maximizing the use of cheap rubber trommel media in mining operations. Rubber trommel media offers several advantages over other materials commonly used in trommel screens. Its durability and flexibility make it ideal for handling abrasive materials and reducing wear and tear on the equipment. Additionally, rubber media is resistant to corrosion and can withstand harsh environmental conditions, making it suitable for various mining applications. One key strategy for optimizing the use of cheap rubber trommel media is proper maintenance and cleaning. Regular inspection of the trommel screen and replacement of worn-out rubber media can prevent inefficiencies and downtime. By addressing issues such as tears, holes, and excessive wear promptly, mining operators can extend the lifespan of their trommel screens and minimize operating costs. Another effective strategy is to adjust the trommel screen settings to optimize performance with rubber media. Fine-tuning parameters such as rotational speed, inclination angle, and feed rate can help achieve the desired screening efficiency while minimizing energy consumption. Experimenting with different configurations and monitoring the results can lead to significant improvements in overall productivity. In addition to maintenance and adjustment, proper handling and storage of rubber trommel media are essential for maximizing its effectiveness. Storing the media in a clean, dry environment away from direct sunlight and extreme temperatures can prevent degradation and prolong its lifespan. Handling the media with care during installation and removal can also minimize the risk of damage and ensure consistent performance. Furthermore, mining operators can explore alternative uses for cheap rubber trommel media to enhance its value and versatility. For example, shredded rubber media can be repurposed for secondary applications such as noise reduction, impact absorption, and erosion control. By finding creative ways to reuse and recycle rubber media, mining companies can reduce waste and contribute to sustainability efforts. Collaborating with reliable suppliers and wholesalers is another crucial aspect of maximizing the benefits of cheap rubber trommel media. Establishing long-term partnerships with reputable vendors can ensure consistent quality, timely delivery, and competitive pricing. Furthermore, suppliers with expertise in mining applications can offer valuable insights and recommendations to help optimize trommel screen performance.How to Choose the Best Wholesaler for Vibrating Fine Rubber Sieves

When it comes to mining operations, the efficiency of equipment can significantly impact productivity and cost-effectiveness. Vibrating fine rubber sieves, commonly used in trommel screens, play a crucial role in separating materials of different sizes. However, acquiring these sieves from reliable wholesalers is essential to ensure quality, durability, and affordability. In this article, we will discuss the key factors to consider when choosing the best wholesaler for vibrating fine rubber sieves. First and foremost, quality should be the primary consideration. Opting for a wholesaler known for providing high-quality rubber sieves can prevent premature wear and tear, ultimately saving time and money in the long run. Look for wholesalers that source their rubber materials from reputable suppliers and adhere to stringent manufacturing standards. Additionally, durability is paramount, especially in demanding mining environments. Vibrating fine rubber sieves must withstand abrasive materials and constant vibration without deteriorating quickly. Wholesalers offering durable rubber sieves constructed from premium materials, such as natural rubber or synthetic compounds, are worth considering.

Cost-effectiveness is another crucial aspect to evaluate when selecting a wholesaler for vibrating fine rubber sieves. While it may be tempting to opt for the cheapest option, it’s essential to strike a balance between price and quality. Consider wholesalers that offer competitive pricing without compromising on the durability and performance of their products.

Furthermore, reliability and consistency are key factors to ensure uninterrupted operations. Choose wholesalers with a proven track record of delivering orders on time and maintaining consistent product quality. This reliability is vital for minimizing downtime and maximizing productivity in mining operations.

Customer support and after-sales service are also important considerations when choosing a wholesaler. Look for companies that provide comprehensive support throughout the purchasing process, from product selection to post-purchase assistance. This includes offering technical guidance, addressing any concerns or issues promptly, and providing warranty coverage for their products.

Moreover, flexibility in customization options can be advantageous for meeting specific mining requirements. Wholesalers that offer customization services, such as tailor-made rubber sieves to fit specific trommel screen dimensions or customized mesh sizes, can provide added value to mining operations.

Transparency and communication are essential aspects of a successful wholesaler-client relationship. Choose wholesalers that prioritize clear and open communication, providing detailed product information, pricing structures, and terms of sale. This transparency fosters trust and ensures a mutually beneficial partnership.

Lastly, consider the reputation and testimonials of the wholesaler within the mining industry. Seek recommendations from colleagues or industry experts and research online reviews to gauge the wholesaler’s reputation for product quality, reliability, and customer satisfaction.

In conclusion, selecting the best wholesaler for vibrating fine rubber sieves involves careful consideration of factors such as quality, durability, cost-effectiveness, reliability, customer support, customization options, transparency, and reputation. By prioritizing these factors and choosing a reputable wholesaler, mining operations can optimize their equipment performance and achieve greater efficiency and profitability.

Additionally, durability is paramount, especially in demanding mining environments. Vibrating fine rubber sieves must withstand abrasive materials and constant vibration without deteriorating quickly. Wholesalers offering durable rubber sieves constructed from premium materials, such as natural rubber or synthetic compounds, are worth considering.

Cost-effectiveness is another crucial aspect to evaluate when selecting a wholesaler for vibrating fine rubber sieves. While it may be tempting to opt for the cheapest option, it’s essential to strike a balance between price and quality. Consider wholesalers that offer competitive pricing without compromising on the durability and performance of their products.

Furthermore, reliability and consistency are key factors to ensure uninterrupted operations. Choose wholesalers with a proven track record of delivering orders on time and maintaining consistent product quality. This reliability is vital for minimizing downtime and maximizing productivity in mining operations.

Customer support and after-sales service are also important considerations when choosing a wholesaler. Look for companies that provide comprehensive support throughout the purchasing process, from product selection to post-purchase assistance. This includes offering technical guidance, addressing any concerns or issues promptly, and providing warranty coverage for their products.

Moreover, flexibility in customization options can be advantageous for meeting specific mining requirements. Wholesalers that offer customization services, such as tailor-made rubber sieves to fit specific trommel screen dimensions or customized mesh sizes, can provide added value to mining operations.

Transparency and communication are essential aspects of a successful wholesaler-client relationship. Choose wholesalers that prioritize clear and open communication, providing detailed product information, pricing structures, and terms of sale. This transparency fosters trust and ensures a mutually beneficial partnership.

Lastly, consider the reputation and testimonials of the wholesaler within the mining industry. Seek recommendations from colleagues or industry experts and research online reviews to gauge the wholesaler’s reputation for product quality, reliability, and customer satisfaction.

In conclusion, selecting the best wholesaler for vibrating fine rubber sieves involves careful consideration of factors such as quality, durability, cost-effectiveness, reliability, customer support, customization options, transparency, and reputation. By prioritizing these factors and choosing a reputable wholesaler, mining operations can optimize their equipment performance and achieve greater efficiency and profitability.