urethane screen mesh,stone screen mesh quotes,screen mesh mining

Exploring the Efficiency of urethane screen mesh in Stone screen mesh mining: A Comprehensive Analysis Urethane screen mesh has emerged as a…

Exploring the Efficiency of urethane screen mesh in Stone screen mesh mining: A Comprehensive Analysis

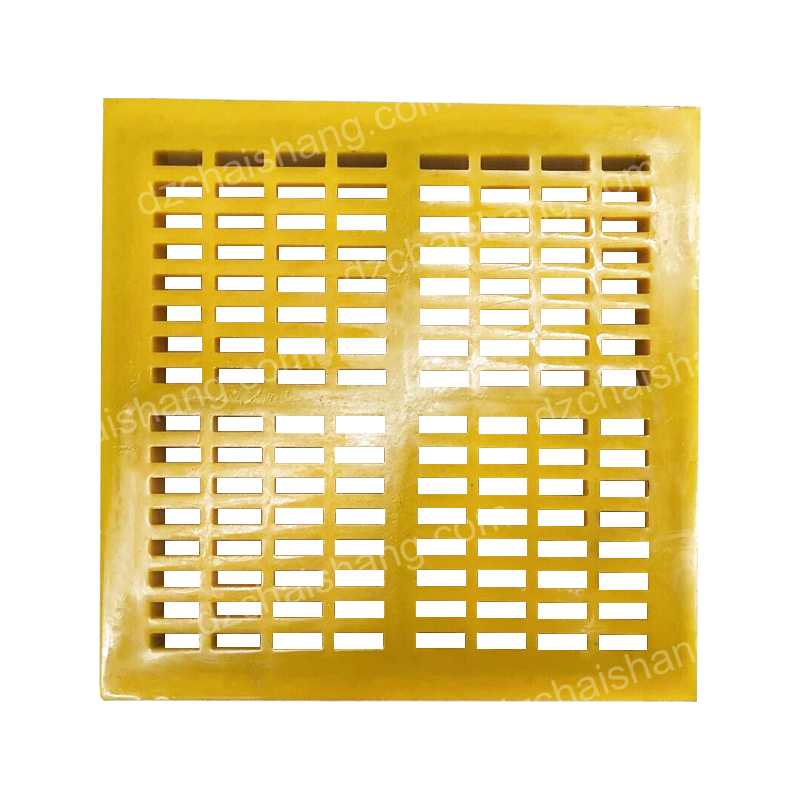

Urethane screen mesh has emerged as a revolutionary product in the mining industry, particularly in stone screen mesh mining. This innovative material has been lauded for its durability, efficiency, and cost-effectiveness, making it a preferred choice for many mining operations worldwide. This article provides a comprehensive analysis of the efficiency of urethane screen mesh in stone screen mesh mining, offering insights into why it has become a popular choice in the industry. Urethane, also known as polyurethane, is a type of polymer that is highly resistant to abrasion, cutting, and tearing. This makes it an ideal material for screen mesh used in mining operations, where durability and resilience are paramount. The use of urethane screen mesh in stone screen mesh mining has been found to significantly reduce the frequency of screen replacements, thereby saving time and reducing operational costs. The efficiency of urethane screen mesh in stone screen mesh mining is not only limited to its durability. It also offers superior performance in terms of screening accuracy. The precision with which urethane screen mesh can filter and sort materials is remarkable. It can effectively separate different sizes of stones, ensuring that only the desired size of stones is extracted. This high level of accuracy reduces wastage and enhances the overall productivity of the mining operation. Another notable advantage of urethane screen mesh is its flexibility. Unlike metal screen meshes, urethane screen meshes can be molded into various shapes and sizes to fit different types of mining equipment. This flexibility allows for a more customized and efficient mining process, further enhancing the productivity of the operation.

The cost-effectiveness of urethane screen mesh is another factor contributing to its popularity in stone screen mesh mining. While the initial cost of urethane screen mesh may be higher than that of traditional metal screen meshes, the long-term savings in terms of reduced maintenance and replacement costs make it a more economical choice in the long run. Furthermore, the increased productivity resulting from the use of urethane screen mesh translates into higher profits, making it a worthwhile investment for mining operations.

Another notable advantage of urethane screen mesh is its flexibility. Unlike metal screen meshes, urethane screen meshes can be molded into various shapes and sizes to fit different types of mining equipment. This flexibility allows for a more customized and efficient mining process, further enhancing the productivity of the operation.

The cost-effectiveness of urethane screen mesh is another factor contributing to its popularity in stone screen mesh mining. While the initial cost of urethane screen mesh may be higher than that of traditional metal screen meshes, the long-term savings in terms of reduced maintenance and replacement costs make it a more economical choice in the long run. Furthermore, the increased productivity resulting from the use of urethane screen mesh translates into higher profits, making it a worthwhile investment for mining operations.