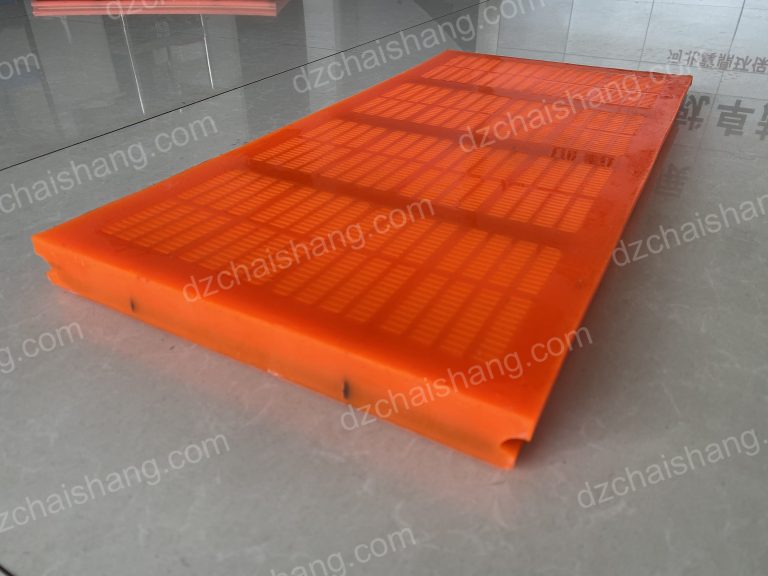

mining Polyurethane Screen Mesh,polyurethane panel

Benefits of Using polyurethane screen mesh in mining Operations Polyurethane screen mesh has become increasingly popular in the mining industry due to…

Benefits of Using polyurethane screen mesh in mining Operations

Polyurethane screen mesh has become increasingly popular in the mining industry due to its numerous benefits and advantages over traditional metal screens. This innovative material is made from polyurethane, a synthetic polymer that offers exceptional durability, flexibility, and resistance to wear and tear. In this article, we will explore the benefits of using polyurethane screen mesh in mining operations. One of the key advantages of polyurethane screen mesh is its superior abrasion resistance. Unlike metal screens, which can easily wear out and require frequent replacement, polyurethane screens are highly durable and can withstand the harsh conditions of mining operations. This means that mining companies can save time and money by reducing the frequency of screen replacements and maintenance. In addition to its durability, polyurethane screen mesh is also highly flexible and can be easily molded into various shapes and sizes to suit different screening applications. This flexibility allows for greater customization and optimization of screening processes, resulting in improved efficiency and productivity. Polyurethane screens can also be manufactured with different opening sizes and patterns to achieve the desired screening performance, making them ideal for a wide range of mining applications. Another benefit of polyurethane screen mesh is its excellent screening efficiency. The unique properties of polyurethane, such as its high elasticity and resilience, allow for efficient screening of materials with high moisture content or fine particles. This results in higher throughput and better separation of materials, leading to increased productivity and profitability for mining operations. Furthermore, polyurethane screen mesh is lightweight and easy to handle, making installation and maintenance quick and simple. Unlike heavy metal screens, which can be cumbersome and difficult to work with, polyurethane screens are easy to transport, install, and replace. This not only saves time and labor costs but also improves overall safety and ergonomics for workers.

Additionally, polyurethane screen mesh is resistant to corrosion and chemical degradation, making it ideal for use in corrosive environments such as mines and quarries. This resistance to corrosion ensures that polyurethane screens have a longer lifespan and require less maintenance compared to metal screens, further reducing operating costs for mining companies. Overall, the benefits of using polyurethane screen mesh in mining operations are clear. From its superior abrasion resistance and flexibility to its excellent screening efficiency and ease of installation, polyurethane screens offer a cost-effective and efficient solution for screening applications in the mining industry. By choosing polyurethane screen mesh, mining companies can improve their operational efficiency, reduce maintenance costs, and enhance overall productivity.

How to Properly Maintain and Extend the Lifespan of Polyurethane Panels in Mining Applications

Polyurethane screen mesh and panels are essential components in the mining industry, as they play a crucial role in separating and classifying materials during the extraction process. These panels are known for their durability, flexibility, and resistance to abrasion, making them ideal for harsh mining environments. However, like any other equipment, polyurethane panels require proper maintenance to ensure optimal performance and longevity. One of the key factors in maintaining polyurethane panels is regular cleaning. Over time, materials such as ore, rocks, and other debris can build up on the surface of the panels, reducing their efficiency and potentially causing damage. To prevent this, it is important to clean the panels regularly using a mild detergent and water. Avoid using harsh chemicals or abrasive materials, as these can damage the polyurethane material and shorten its lifespan. In addition to cleaning, it is also important to inspect the panels regularly for any signs of wear or damage. Look for tears, holes, or any other visible defects that could affect the performance of the panels. If any damage is found, it is important to address it immediately to prevent further deterioration. In some cases, damaged panels may need to be replaced to ensure the continued efficiency of the screening process. Another important aspect of maintaining polyurethane panels is proper storage when not in use. Store the panels in a clean, dry area away from direct sunlight and extreme temperatures. Avoid stacking heavy objects on top of the panels, as this can cause deformation and damage. By storing the panels properly, you can extend their lifespan and ensure that they are ready for use when needed.When installing polyurethane panels, it is important to follow the manufacturer’s guidelines to ensure proper fit and alignment. Improper installation can lead to premature wear and reduced efficiency. Make sure that the panels are securely fastened and that there are no gaps or overlaps that could affect their performance. If you are unsure about the installation process, consult with a professional to ensure that the panels are installed correctly. In addition to regular maintenance, it is also important to monitor the performance of the polyurethane panels during operation. Keep an eye on the screening process and look for any signs of inefficiency or abnormal wear. If you notice any issues, address them promptly to prevent further damage and ensure the continued effectiveness of the panels. By following these maintenance tips, you can extend the lifespan of your polyurethane panels and ensure that they continue to perform at their best in mining applications. Proper maintenance not only helps to protect your investment but also ensures the safety and efficiency of the screening process. With regular cleaning, inspection, storage, and monitoring, you can maximize the lifespan of your polyurethane panels and keep your mining operations running smoothly.