批發網篩、高頻篩、PU板

工業應用使用批發網篩的好處 高頻篩網和PU面板如何提高製造流程的效率 除了高頻螢幕之外,PU 面板是製造商可以用來提高流程效率的另一種工具。 PU 面板由聚氨酯製成,這是一種耐用且柔韌的材料,非常適合篩選應用。這些面板設計用於安裝在振動篩上,提供耐磨表面,可以承受持續使用的嚴酷條件。與由鋼或橡膠製成的傳統篩板不同,PU 板更耐磨損,從而延長使用壽命並降低維護成本。這種耐用性使 PU 板成為希望提高篩選操作效率的製造商的經濟高效的解決方案。聚氨酯的柔韌性能吸收振動,從而創造更安靜的工作環境。這可以提高員工士氣和生產力,因為工人不太可能因過度噪音而分心或疲勞。這兩種技術的結合可以更快地篩選材料、提高產量並提高產品品質。這可以為製造商帶來顯著的成本節省,並在市場上獲得競爭優勢。透過將這些技術融入其流程中,公司可以實現更高的產量、更好的產品品質並降低維護成本。在當今競爭激烈的製造領域,投資高頻螢幕和 PU 面板對於希望保持領先地位的公司來說是明智的選擇。 In the world of manufacturing, efficiency is key. Companies are constantly…

工業應用使用批發網篩的好處

高頻篩網和PU面板如何提高製造流程的效率

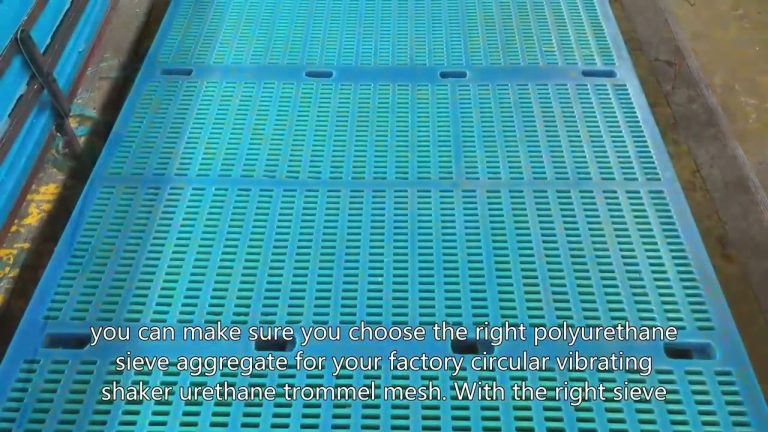

除了高頻螢幕之外,PU 面板是製造商可以用來提高流程效率的另一種工具。 PU 面板由聚氨酯製成,這是一種耐用且柔韌的材料,非常適合篩選應用。這些面板設計用於安裝在振動篩上,提供耐磨表面,可以承受持續使用的嚴酷條件。與由鋼或橡膠製成的傳統篩板不同,PU 板更耐磨損,從而延長使用壽命並降低維護成本。這種耐用性使 PU 板成為希望提高篩選操作效率的製造商的經濟高效的解決方案。聚氨酯的柔韌性能吸收振動,從而創造更安靜的工作環境。這可以提高員工士氣和生產力,因為工人不太可能因過度噪音而分心或疲勞。這兩種技術的結合可以更快地篩選材料、提高產量並提高產品品質。這可以為製造商帶來顯著的成本節省,並在市場上獲得競爭優勢。透過將這些技術融入其流程中,公司可以實現更高的產量、更好的產品品質並降低維護成本。在當今競爭激烈的製造領域,投資高頻螢幕和 PU 面板對於希望保持領先地位的公司來說是明智的選擇。

In the world of manufacturing, efficiency is key. Companies are constantly looking for ways to streamline their processes, reduce waste, and increase productivity. One way that manufacturers can achieve these goals is by incorporating high frequency screens and PU panels into their operations.

High frequency screens are a type of vibrating screen that operates at a high frequency, typically between 3600-7200 RPM. This high frequency allows for more efficient screening of materials, resulting in a higher throughput and improved product quality. These screens are commonly used in industries such as mining, aggregate processing, and construction.

In addition to high frequency screens, PU panels are another tool that manufacturers can use to improve efficiency in their processes. PU panels are made from polyurethane, a durable and flexible material that is ideal for use in screening applications. These panels are designed to fit onto vibrating screens, providing a wear-resistant surface that can withstand the rigors of constant use.

One of the main advantages of PU panels is their longevity. Unlike traditional screen panels made from steel or rubber, PU panels are more resistant to wear and tear, resulting in a longer lifespan and reduced maintenance costs. This durability makes PU panels a cost-effective solution for manufacturers looking to improve the efficiency of their screening operations.

Another benefit of PU panels is their ability to reduce noise levels in the workplace. The flexible nature of polyurethane absorbs vibrations, resulting in a quieter working environment. This can lead to improved employee morale and productivity, as workers are less likely to be distracted or fatigued by excessive noise.

When used in conjunction with high frequency screens, PU panels can further enhance the efficiency of manufacturing processes. The combination of these two technologies allows for faster screening of materials, increased throughput, and improved product quality. This can result in significant cost savings for manufacturers, as well as a competitive edge in the marketplace.

Overall, high frequency screens and PU panels are valuable tools that can help manufacturers improve efficiency in their operations. By incorporating these technologies into their processes, companies can achieve higher throughput, better product quality, and reduced maintenance costs. In today’s competitive manufacturing landscape, investing in high frequency screens and PU panels is a smart choice for companies looking to stay ahead of the curve.