批發篩網廠,振動篩篩網

使用批發網篩廠產品進行工業應用的好處 如何根據您的特定需求選擇合適的振動篩篩網 選擇振動篩篩網時,除了材質、尺寸、形狀外,考慮篩網的編織圖案也很重要。篩網有多種編織圖案,包括平織、斜紋編織和荷蘭編織。每種編織圖案都有其獨特的性能和優勢,因此選擇最適合您特定需求的編織圖案非常重要。斜紋編織網篩比平織篩網更堅固、更耐用,使其適合重型應用。荷蘭編織篩網具有緊密的編織圖案,可提供出色的過濾性能,使其成為需要精確顆粒分離的應用的理想選擇。至關重要。透過考慮材料、尺寸、形狀和編織圖案等因素,您可以選擇滿足您的要求並提供高品質結果的網篩。無論您是需要用於腐蝕環境的耐用不銹鋼網篩,還是需要快速輕鬆更換的柔性聚氨酯網篩,都有多種選擇可以滿足您的特定需求。 When it comes to choosing the right vibrating screen screen mesh for your specific needs, there are several factors…

使用批發網篩廠產品進行工業應用的好處

如何根據您的特定需求選擇合適的振動篩篩網

選擇振動篩篩網時,除了材質、尺寸、形狀外,考慮篩網的編織圖案也很重要。篩網有多種編織圖案,包括平織、斜紋編織和荷蘭編織。每種編織圖案都有其獨特的性能和優勢,因此選擇最適合您特定需求的編織圖案非常重要。斜紋編織網篩比平織篩網更堅固、更耐用,使其適合重型應用。荷蘭編織篩網具有緊密的編織圖案,可提供出色的過濾性能,使其成為需要精確顆粒分離的應用的理想選擇。至關重要。透過考慮材料、尺寸、形狀和編織圖案等因素,您可以選擇滿足您的要求並提供高品質結果的網篩。無論您是需要用於腐蝕環境的耐用不銹鋼網篩,還是需要快速輕鬆更換的柔性聚氨酯網篩,都有多種選擇可以滿足您的特定需求。

When it comes to choosing the right vibrating screen screen mesh for your specific needs, there are several factors to consider. The mesh screen is an essential component of a vibrating screen, as it determines the size and shape of the particles that can pass through the screen. This, in turn, affects the efficiency and effectiveness of the screening process.

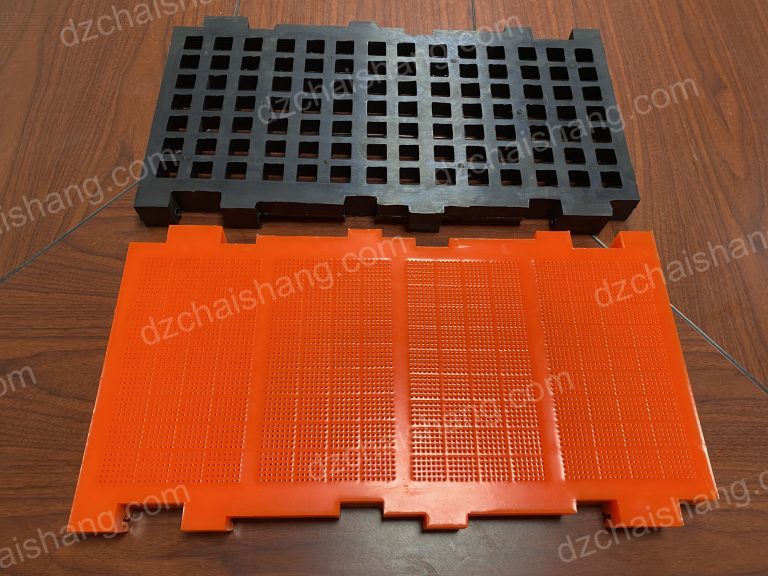

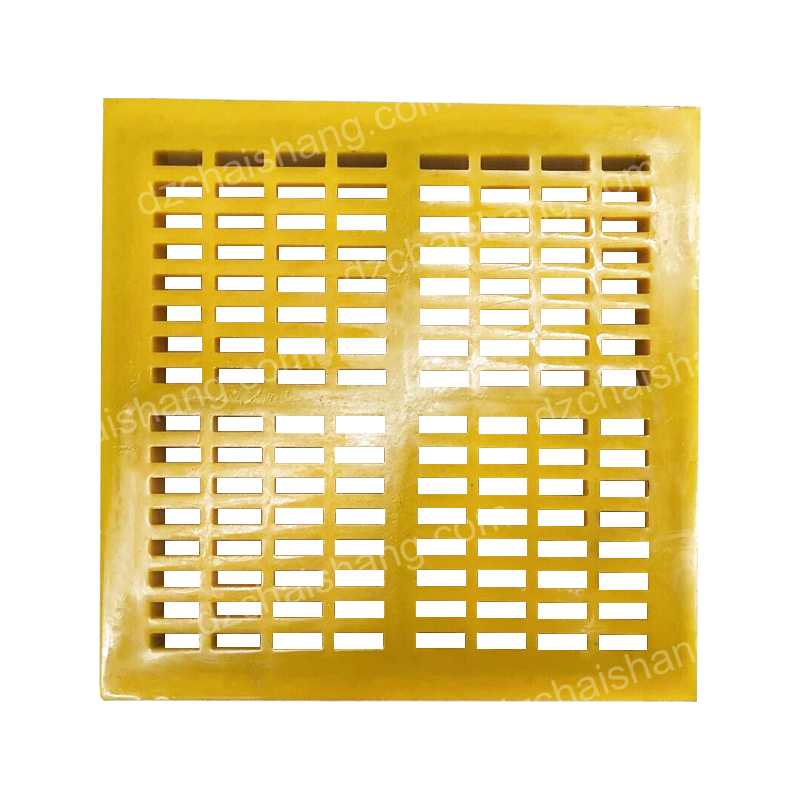

Stainless steel mesh screens are durable and resistant to corrosion, making them ideal for applications where the screen will be exposed to moisture or harsh chemicals. High carbon steel mesh screens are strong and abrasion-resistant, making them suitable for heavy-duty applications. polyurethane mesh screens are flexible and easy to install, making them a popular choice for applications where quick and easy screen replacement is necessary.

Another important factor to consider when choosing a vibrating screen screen mesh is the size of the mesh openings. The size of the mesh openings will determine the size of the particles that can pass through the screen. If the mesh openings are too small, they may become clogged with material, reducing the efficiency of the screening process. If the mesh openings are too large, they may allow oversized particles to pass through the screen, reducing the quality of the final product.

It’s also important to consider the shape of the mesh openings when choosing a vibrating screen screen mesh. Mesh screens are available in a variety of shapes, including square, rectangular, and round. The shape of the mesh openings can affect the efficiency of the screening process, as well as the quality of the final product. Square mesh openings are ideal for applications where precise sizing is required, while round mesh openings are better suited for applications where self-cleaning properties are important.

In addition to material, size, and shape, it’s also important to consider the weave pattern of the mesh screen when choosing a vibrating screen screen mesh. Mesh screens are available in a variety of weave patterns, including plain weave, twill weave, and Dutch weave. Each weave pattern has its own unique properties and advantages, so it’s important to choose the weave pattern that best suits your specific needs.

Plain weave mesh screens are simple and cost-effective, making them a popular choice for general-purpose screening applications. Twill weave mesh screens are stronger and more durable than plain weave screens, making them suitable for heavy-duty applications. Dutch weave mesh screens have a tight weave pattern that provides excellent filtration properties, making them ideal for applications where precise particle separation is required.

In conclusion, choosing the right vibrating screen screen mesh for your specific needs is essential for ensuring the efficiency and effectiveness of the screening process. By considering factors such as material, size, shape, and weave pattern, you can select a mesh screen that meets your requirements and delivers high-quality results. Whether you need a durable stainless steel mesh screen for a corrosive environment or a flexible polyurethane mesh screen for quick and easy replacement, there is a wide range of options available to suit your specific needs.