什麼是聚氨酯板、聚氨酯屏風、PU屏風板

了解聚氨酯板:成分、用途和優點 探索聚氨酯篩網:在工業過濾和分離中的應用 PU篩板在振動篩分設備上的優點 聚氨酯,通常稱為 PU,是一種多功能聚合物,由於其卓越的性能已進入無數的工業應用。在其眾多用途中,聚氨酯在採礦、骨材和回收業的篩分設備製造中尤其受到重視。聚氨酯板、聚氨酯篩網和 PU 篩板這些術語通常描述由這種材料製成的振動篩分設備中使用的組件。了解 PU 篩板在此類應用中的優勢對於依賴精確高效的材料分離的行業至關重要。其固有的韌性和耐磨性使其成為加工磨料的篩選應用的理想選擇。該板可以根據應用的具體要求製造成不同等級的硬度,從而可以進行客製化以優化性能和壽命。它們在濕式和乾式篩選中特別有效,這使得它們具有高度的通用性。聚氨酯的彈性比傳統的金屬絲網篩網有顯著的優勢。這種靈活性使篩子能夠吸收衝擊力並減少堵塞(顆粒堵塞篩孔)的可能性,從而保持效率和產量。 。與金屬替代品相比,它們重量輕,這使得它們更容易操作並減少篩選設備的負載。這可以降低能耗,由於減少了應力和振動,還可以延長機器的使用壽命。聚氨酯具有很強的耐磨性,這是礦物和礦石等材料篩選的常見問題。這種阻力意味著篩板的使用壽命更長,減少了更換頻率並最大限度地減少了維護停機時間。因此,隨著時間的推移,這可以顯著節省成本。與暴露於某些材料或環境時可能生鏽或腐蝕的金屬篩網不同,聚氨酯可以保持其完整性。這種特性在涉及腐蝕性物質的應用中或在高濕度或暴露於水的環境中特別有益。篩選設備可能會非常吵鬧,尤其是在工業環境中。 PU 篩板可以幫助抑制篩分過程中產生的噪音,有助於創造更舒適、更合規的工作環境。它們通常比金屬屏幕更輕,這可以減少與運輸相關的碳足跡。此外,它們的耐用性意味著無需頻繁更換,從而減少浪費。它們的耐用性、耐磨性和耐腐蝕性、降噪能力和能源效率使其成為需要可靠和有效材料分離的行業的絕佳選擇。隨著技術的進步和對更永續工業解決方案的需求的增長,聚氨酯在篩分應用中的作用可能會擴大,進一步鞏固其作為高性能篩分解決方案首選材料的地位。 Transitioning from the polyurethane board, the polyurethane screen represents a…

了解聚氨酯板:成分、用途和優點

探索聚氨酯篩網:在工業過濾和分離中的應用

PU篩板在振動篩分設備上的優點

聚氨酯,通常稱為 PU,是一種多功能聚合物,由於其卓越的性能已進入無數的工業應用。在其眾多用途中,聚氨酯在採礦、骨材和回收業的篩分設備製造中尤其受到重視。聚氨酯板、聚氨酯篩網和 PU 篩板這些術語通常描述由這種材料製成的振動篩分設備中使用的組件。了解 PU 篩板在此類應用中的優勢對於依賴精確高效的材料分離的行業至關重要。其固有的韌性和耐磨性使其成為加工磨料的篩選應用的理想選擇。該板可以根據應用的具體要求製造成不同等級的硬度,從而可以進行客製化以優化性能和壽命。它們在濕式和乾式篩選中特別有效,這使得它們具有高度的通用性。聚氨酯的彈性比傳統的金屬絲網篩網有顯著的優勢。這種靈活性使篩子能夠吸收衝擊力並減少堵塞(顆粒堵塞篩孔)的可能性,從而保持效率和產量。 。與金屬替代品相比,它們重量輕,這使得它們更容易操作並減少篩選設備的負載。這可以降低能耗,由於減少了應力和振動,還可以延長機器的使用壽命。聚氨酯具有很強的耐磨性,這是礦物和礦石等材料篩選的常見問題。這種阻力意味著篩板的使用壽命更長,減少了更換頻率並最大限度地減少了維護停機時間。因此,隨著時間的推移,這可以顯著節省成本。與暴露於某些材料或環境時可能生鏽或腐蝕的金屬篩網不同,聚氨酯可以保持其完整性。這種特性在涉及腐蝕性物質的應用中或在高濕度或暴露於水的環境中特別有益。篩選設備可能會非常吵鬧,尤其是在工業環境中。 PU 篩板可以幫助抑制篩分過程中產生的噪音,有助於創造更舒適、更合規的工作環境。它們通常比金屬屏幕更輕,這可以減少與運輸相關的碳足跡。此外,它們的耐用性意味著無需頻繁更換,從而減少浪費。它們的耐用性、耐磨性和耐腐蝕性、降噪能力和能源效率使其成為需要可靠和有效材料分離的行業的絕佳選擇。隨著技術的進步和對更永續工業解決方案的需求的增長,聚氨酯在篩分應用中的作用可能會擴大,進一步鞏固其作為高性能篩分解決方案首選材料的地位。

Transitioning from the polyurethane board, the polyurethane screen represents a significant advancement in screening technology. These screens are designed to facilitate efficient separation and filtration of materials in industries such as mining, quarrying, and recycling. The unique structure of polyurethane screens, combined with their material properties, allows for improved screening performance. They effectively reduce blinding and pegging, common challenges in screening processes, thereby enhancing productivity and operational efficiency.

Moreover, the adaptability of polyurethane screens to various screening environments is noteworthy. They can be customized to fit different screening machines and applications, making them a versatile solution for many industrial needs. This adaptability extends to the pu screen panel, a specific type of polyurethane screen designed for modular applications.

The pu screen panel embodies the essence of polyurethane’s advantages in a modular format. These panels are easily replaceable and can be configured to meet the specific requirements of a screening process. Their modular nature allows for quick and easy maintenance, reducing downtime and increasing the overall efficiency of the operation. Furthermore, PU screen panels are available in different designs and apertures, enabling precise separation and filtration according to the material characteristics and process requirements.

In conclusion, the exploration of polyurethane screens, from polyurethane board to PU screen panel, reveals their critical role in industrial filtration and separation. Their exceptional material properties, combined with innovative design and adaptability, make them an indispensable tool in enhancing the efficiency and effectiveness of industrial processes. As industries continue to evolve and demand more from their filtration and separation solutions, polyurethane screens stand ready to meet these challenges, offering a durable, efficient, and versatile option for various applications.

The Advantages of PU Screen Panels in Vibration Screening Equipment

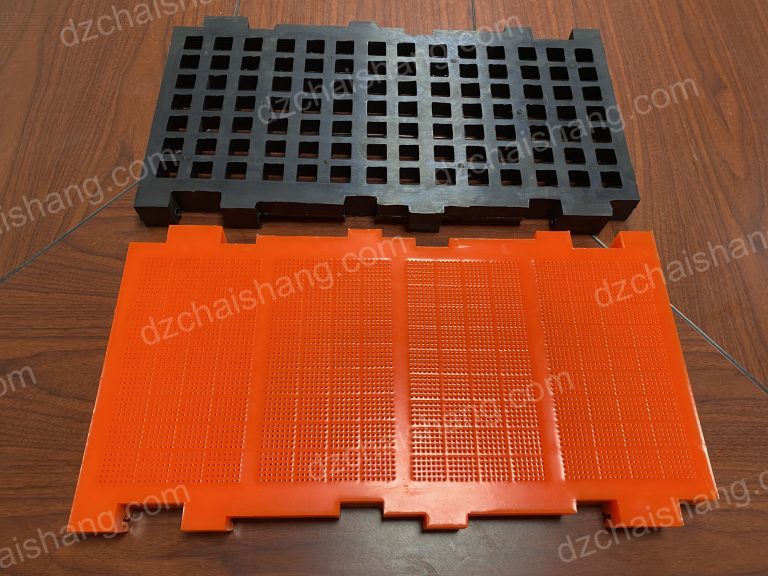

Polyurethane, commonly referred to as PU, is a versatile polymer that has found its way into a myriad of industrial applications due to its exceptional properties. Among its many uses, polyurethane is particularly valued in the manufacturing of screening equipment for the mining, aggregate, and recycling industries. Polyurethane board, polyurethane screen, and PU screen panel are terms that often describe the components made from this material that are used in vibration screening equipment. Understanding the advantages of PU screen panels in such applications is crucial for industries that rely on precise and efficient material separation.

Polyurethane board is a solid, durable material that can be cast or molded into a variety of shapes and sizes. Its inherent toughness and resistance to wear and tear make it an ideal candidate for use in screening applications where abrasive materials are processed. The board can be fabricated with different levels of hardness, depending on the specific requirements of the application, which allows for customization to optimize performance and longevity.

Polyurethane screens are designed to facilitate the separation of particles of different sizes. They are particularly effective in wet and dry screening, which makes them highly versatile. The elasticity of polyurethane provides a significant advantage over traditional wire mesh screens. This flexibility allows the screen to absorb impact and reduce the likelihood of blinding, where particles clog the screen openings, thus maintaining efficiency and throughput.

PU screen panels are modular and can be easily fitted into various types of vibrating screens. They are lightweight compared to metal alternatives, which makes them easier to handle and reduces the load on screening equipment. This can lead to lower energy consumption and can also extend the life of the machinery due to reduced stress and vibration.

One of the primary advantages of PU screen panels is their exceptional wear resistance. Polyurethane is highly resistant to abrasion, which is a common issue in the screening of materials like minerals and ores. This resistance translates to a longer service life for the screen panels, reducing the frequency of replacements and minimizing downtime for maintenance. Consequently, this can lead to significant cost savings over time.

Moreover, PU screen panels offer excellent corrosion resistance. Unlike metal screens that can rust or corrode when exposed to certain materials or environments, polyurethane maintains its integrity. This property is particularly beneficial in applications involving corrosive substances or in settings with high humidity or exposure to water.

The noise reduction capabilities of polyurethane are another noteworthy benefit. Screening equipment can be quite noisy, especially in industrial settings. PU screen panels can help dampen the noise produced during the screening process, contributing to a more pleasant and compliant working environment.

In terms of environmental impact, PU screen panels are often seen as a more sustainable option. They are typically lighter than metal screens, which can reduce the carbon footprint associated with transportation. Additionally, their durability means that they need to be replaced less frequently, resulting in less waste.

In conclusion, the use of polyurethane board, polyurethane screen, and PU screen panel in vibration screening equipment offers a multitude of advantages. Their durability, resistance to wear and corrosion, noise reduction capabilities, and energy efficiency make them an excellent choice for industries that require reliable and effective material separation. As technology advances and the demand for more sustainable industrial solutions grows, the role of polyurethane in screening applications is likely to expand, further cementing its status as a material of choice for high-performance screening solutions.