振動篩,振動篩,聚氨酯篩

了解振動篩的功能與用途 聚氨酯篩網相對於傳統篩網的優點 振動篩,也稱為振動篩,是各行業的必備工具,因為它們有助於分離和過濾不同尺寸的物料。這些篩網多年來不斷發展,最新的創新是聚氨酯篩網。本文將深入探討聚氨酯篩網相對於傳統篩網的優點。與由金屬或金屬絲網製成的傳統篩網不同,聚氨酯篩網由柔性材料製成,可以承受高水平的應變而不會撕裂或斷裂。這使得它們非常適合採礦和採石等重型應用,在這些應用中,篩網會承受巨大的壓力和磨損。因此,聚氨酯篩網的使用壽命更長,減少了頻繁更換的需要,從而降低了營運成本。由於其靈活性,它們具有更高的篩分效率,這使得它們能夠隨著被篩選的材料振動和移動。這種運動增加了較小顆粒通過篩網的機會,從而實現更精細、更準確的分離。此外,與金屬篩網相比,聚氨酯篩網的噪音水平較低。聚氨酯的柔軟特性可以吸收振動,減少篩選過程中產生的噪音。此功能不僅創造了更有利的工作環境,而且符合許多行業的噪音法規標準。傳統的篩網,尤其是金屬製成的篩網,在暴露於水分和某些化學物質時容易生鏽和腐蝕。另一方面,聚氨酯是一種合成材料,耐水、耐油和大多數化學物質。這種阻力確保螢幕即使在惡劣的條件下也能保持其結構完整性和性能,進一步提高其耐用性和使用壽命。它們可以製造成各種尺寸、形狀和配置,以適應不同的應用。這種靈活性允許設計具有特定特性的篩網,例如用於精確篩分的不同孔徑尺寸或易於安裝和更換的不同面板尺寸。此外,聚氨酯篩網可以生產成各種顏色,可根據其應用來區分篩網或滿足特定環境的美學要求。這些螢幕的使用壽命較長,這意味著更換頻率較低,從而減少了浪費。此外,聚氨酯是一種可回收材料。在使用壽命結束時,這些篩網可以回收成其他有用的產品,從而減少對環境的影響。它們的耐用性、高性能、耐環境條件、客製化選項以及對環境永續性的貢獻使它們成為各行業的卓越選擇。隨著技術的不斷進步,預計聚氨酯篩網的使用將變得更加廣泛,從而進一步徹底改變篩分過程。 The Advantages of polyurethane screens over Traditional Sieve Screens Vibrating screens, also known as vibrating sieve screens, are essential…

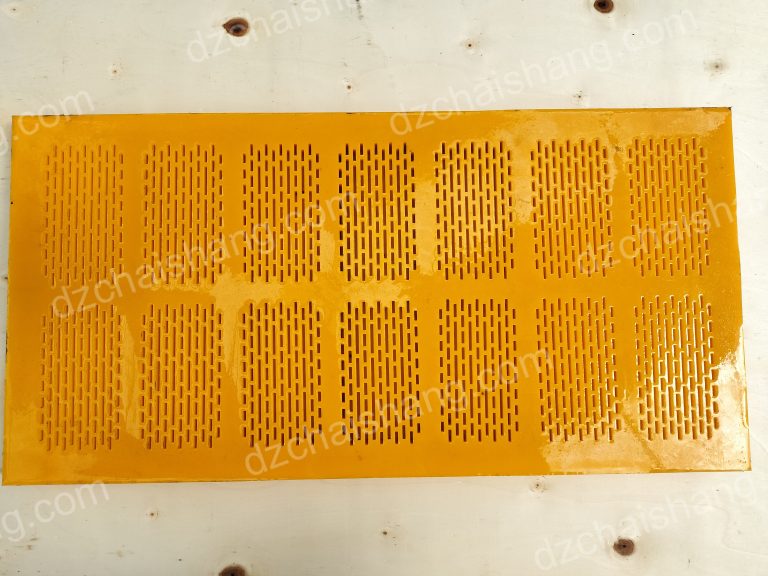

了解振動篩的功能與用途

聚氨酯篩網相對於傳統篩網的優點

振動篩,也稱為振動篩,是各行業的必備工具,因為它們有助於分離和過濾不同尺寸的物料。這些篩網多年來不斷發展,最新的創新是聚氨酯篩網。本文將深入探討聚氨酯篩網相對於傳統篩網的優點。與由金屬或金屬絲網製成的傳統篩網不同,聚氨酯篩網由柔性材料製成,可以承受高水平的應變而不會撕裂或斷裂。這使得它們非常適合採礦和採石等重型應用,在這些應用中,篩網會承受巨大的壓力和磨損。因此,聚氨酯篩網的使用壽命更長,減少了頻繁更換的需要,從而降低了營運成本。由於其靈活性,它們具有更高的篩分效率,這使得它們能夠隨著被篩選的材料振動和移動。這種運動增加了較小顆粒通過篩網的機會,從而實現更精細、更準確的分離。此外,與金屬篩網相比,聚氨酯篩網的噪音水平較低。聚氨酯的柔軟特性可以吸收振動,減少篩選過程中產生的噪音。此功能不僅創造了更有利的工作環境,而且符合許多行業的噪音法規標準。傳統的篩網,尤其是金屬製成的篩網,在暴露於水分和某些化學物質時容易生鏽和腐蝕。另一方面,聚氨酯是一種合成材料,耐水、耐油和大多數化學物質。這種阻力確保螢幕即使在惡劣的條件下也能保持其結構完整性和性能,進一步提高其耐用性和使用壽命。它們可以製造成各種尺寸、形狀和配置,以適應不同的應用。這種靈活性允許設計具有特定特性的篩網,例如用於精確篩分的不同孔徑尺寸或易於安裝和更換的不同面板尺寸。此外,聚氨酯篩網可以生產成各種顏色,可根據其應用來區分篩網或滿足特定環境的美學要求。這些螢幕的使用壽命較長,這意味著更換頻率較低,從而減少了浪費。此外,聚氨酯是一種可回收材料。在使用壽命結束時,這些篩網可以回收成其他有用的產品,從而減少對環境的影響。它們的耐用性、高性能、耐環境條件、客製化選項以及對環境永續性的貢獻使它們成為各行業的卓越選擇。隨著技術的不斷進步,預計聚氨酯篩網的使用將變得更加廣泛,從而進一步徹底改變篩分過程。

The Advantages of polyurethane screens over Traditional Sieve Screens

Vibrating screens, also known as vibrating sieve screens, are essential tools in various industries as they help to separate and filter different sized materials. These screens have evolved over the years, with the latest innovation being the polyurethane screen. This article will delve into the advantages of polyurethane screens over traditional sieve screens.

Polyurethane screens have gained popularity due to their durability and efficiency. Unlike traditional sieve screens made from metal or wire mesh, polyurethane screens are made from a flexible material that can withstand high levels of strain without tearing or breaking. This makes them ideal for heavy-duty applications such as mining and quarrying, where screens are subjected to intense pressure and wear. Consequently, polyurethane screens have a longer lifespan, reducing the need for frequent replacements and thus lowering operational costs.

In addition to their durability, polyurethane screens offer superior performance. They have a higher screening efficiency due to their flexibility, which allows them to vibrate and move with the material being screened. This movement increases the chances of smaller particles passing through the screen, resulting in a more refined and accurate separation. Furthermore, polyurethane screens have a lower noise level compared to metal screens. The soft nature of polyurethane absorbs the vibration, reducing the noise produced during the screening process. This feature not only creates a more conducive working environment but also complies with noise regulation standards in many industries.

Another significant advantage of polyurethane screens is their resistance to environmental conditions. Traditional sieve screens, especially those made from metal, are prone to rust and corrosion when exposed to moisture and certain chemicals. On the other hand, polyurethane is a synthetic material that is resistant to water, oil, and most chemicals. This resistance ensures that the screens maintain their structural integrity and performance even in harsh conditions, further enhancing their durability and lifespan.

Polyurethane screens also offer the advantage of customization. They can be manufactured in a wide range of sizes, shapes, and configurations to suit different applications. This flexibility allows for the design of screens with specific characteristics such as varying hole sizes for precise screening or different panel sizes for easy installation and replacement. Moreover, polyurethane screens can be produced in various colors, which can be used to differentiate screens based on their application or to match the aesthetic requirements of a particular setting.

Lastly, the use of polyurethane screens contributes to environmental sustainability. The long lifespan of these screens means less frequent replacements, leading to reduced waste. Additionally, polyurethane is a recyclable material. At the end of their useful life, these screens can be recycled into other useful products, reducing the environmental impact.

In conclusion, polyurethane screens offer numerous advantages over traditional sieve screens. Their durability, high performance, resistance to environmental conditions, customization options, and contribution to environmental sustainability make them a superior choice in various industries. As technology continues to advance, it is expected that the use of polyurethane screens will become even more widespread, further revolutionizing the screening process.