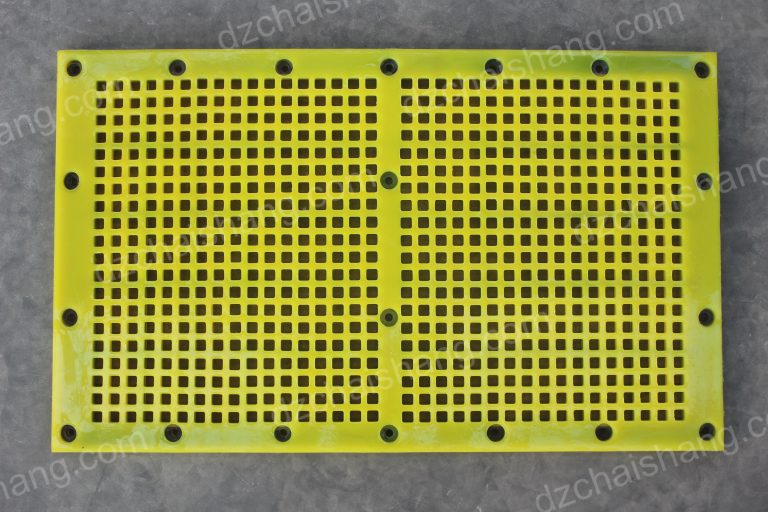

振動篩板、PU塗層金屬絲篩板、聚氨酯網篩

利用振動篩板和聚氨酯網篩最大限度地提高效率 聚氨酯網篩是一種由聚氨酯網製成的篩網,這種材料以其優異的耐磨性和較長的使用壽命而聞名。網狀設計具有高度的靈活性,使其能夠有效地篩選各種材料。聚氨酯網篩也易於清潔和維護,進一步提高了其效率。振動篩板能夠處理多種材料,可以提高篩分過程的吞吐量,從而提高生產率。 PU 塗層金屬絲篩板表面光滑,經久耐用,可減少停機時間和維護成本,從而顯著節省成本。聚氨酯網篩以其靈活性和易於維護的特點,可以提高篩分過程的效率,從而提高產品品質。的可以顯著提高採礦和骨料行業篩選過程效率的解決方案。透過提高吞吐量、減少停機時間和維護成本以及提高產品質量,這些先進的篩選解決方案可以顯著提高生產率並節省成本。因此,對於希望最大限度提高營運效率的企業來說,投資這些先進的篩檢解決方案可能是明智的決定。 The PU coated wire sieve panel is another innovative solution that can enhance the screening process. PU, or…

利用振動篩板和聚氨酯網篩最大限度地提高效率

聚氨酯網篩是一種由聚氨酯網製成的篩網,這種材料以其優異的耐磨性和較長的使用壽命而聞名。網狀設計具有高度的靈活性,使其能夠有效地篩選各種材料。聚氨酯網篩也易於清潔和維護,進一步提高了其效率。振動篩板能夠處理多種材料,可以提高篩分過程的吞吐量,從而提高生產率。 PU 塗層金屬絲篩板表面光滑,經久耐用,可減少停機時間和維護成本,從而顯著節省成本。聚氨酯網篩以其靈活性和易於維護的特點,可以提高篩分過程的效率,從而提高產品品質。的可以顯著提高採礦和骨料行業篩選過程效率的解決方案。透過提高吞吐量、減少停機時間和維護成本以及提高產品質量,這些先進的篩選解決方案可以顯著提高生產率並節省成本。因此,對於希望最大限度提高營運效率的企業來說,投資這些先進的篩檢解決方案可能是明智的決定。

The PU coated wire sieve panel is another innovative solution that can enhance the screening process. PU, or polyurethane, is a type of plastic that is known for its exceptional durability and resistance to wear, tear, and abrasion. When used to coat a wire sieve panel, it creates a highly durable and long-lasting screen that can withstand the rigors of the screening process. The PU coating also provides a smooth surface that allows materials to slide easily over the screen, reducing the likelihood of clogging and improving the efficiency of the screening process.

The use of these advanced screening solutions can significantly improve the efficiency of the screening process. The vibrating screen panel, with its ability to handle a wide range of materials, can increase the throughput of the screening process, leading to increased productivity. The PU coated wire sieve panel, with its smooth surface and exceptional durability, can reduce downtime and maintenance costs, leading to significant cost savings. The urethane mesh sieve, with its flexibility and ease of maintenance, can enhance the efficiency of the screening process, leading to improved product quality.

In conclusion, the vibrating screen panel, PU coated wire sieve panel, and urethane mesh sieve are innovative solutions that can significantly enhance the efficiency of the screening process in the mining and aggregate industries. By improving throughput, reducing downtime and maintenance costs, and enhancing product quality, these advanced screening solutions can lead to significant productivity gains and cost savings. Therefore, for businesses looking to maximize efficiency in their operations, investing in these advanced screening solutions could be a wise decision.