振動篩網供應商,批發篩網尺寸

使用優質振動篩網供應商的好處 如何為您的應用選擇合適的批發篩網尺寸 在為您的應用選擇合適的批發篩網尺寸時,需要考慮幾個因素。最重要的考慮因素之一是您要篩選的材料類型。不同的材料需要不同的篩孔尺寸才能有效分離顆粒。例如,細目尺寸通常用於篩選沙子和礫石等材料,而較大的目數更適合篩選較大的顆粒,如岩石和石頭。需的尺寸物料的輸出尺寸。如果您希望生產特定尺寸的材料,則需要選擇能夠實現該輸出的網格尺寸。例如,如果您希望生產細砂,則需要能夠分離出較小顆粒的篩孔尺寸。篩網的容量將決定在給定時間內可以處理多少材料。如果您處理大量材料,則需要具有更大容量和更大網孔尺寸的篩網,以適應增加的吞吐量。品質.選擇信譽良好的振動篩網供應商對於確保您獲得性能有效且使用壽命長的高品質產品至關重要。尋找提供多種篩網尺寸和材質可供選擇,以及滿足您的特定需求的客製化選項的供應商。雖然選擇最便宜的選項可能很誘人,但重要的是要記住,對於振動篩網來說,品質是關鍵。從長遠來看,預先投資高品質的產品可以減少維護和更換成本,從而節省您的時間和金錢。重要。選擇供應商時,請考慮材料類型、產量尺寸、產能和整體品質等因素。花時間研究並選擇正確的篩網尺寸,您可以確保您的振動篩能夠有效地分離顆粒並為您的特定應用產生所需的輸出尺寸。 In conclusion, choosing high-quality vibrating screen mesh suppliers is essential for maximizing the performance and efficiency of your screening…

使用優質振動篩網供應商的好處

如何為您的應用選擇合適的批發篩網尺寸

In conclusion, choosing high-quality vibrating screen mesh suppliers is essential for maximizing the performance and efficiency of your screening operations. Quality suppliers offer durable, versatile, and reliable screen mesh that can enhance the durability, versatility, and efficiency of your screening process. By investing in high-quality screen mesh, you can achieve optimal screening results, improve productivity, and reduce maintenance costs in the long run. So, when it comes to selecting vibrating screen mesh suppliers, prioritize quality to reap the benefits of superior screening performance.

How to Choose the Right Wholesale screen mesh sizes for Your Application

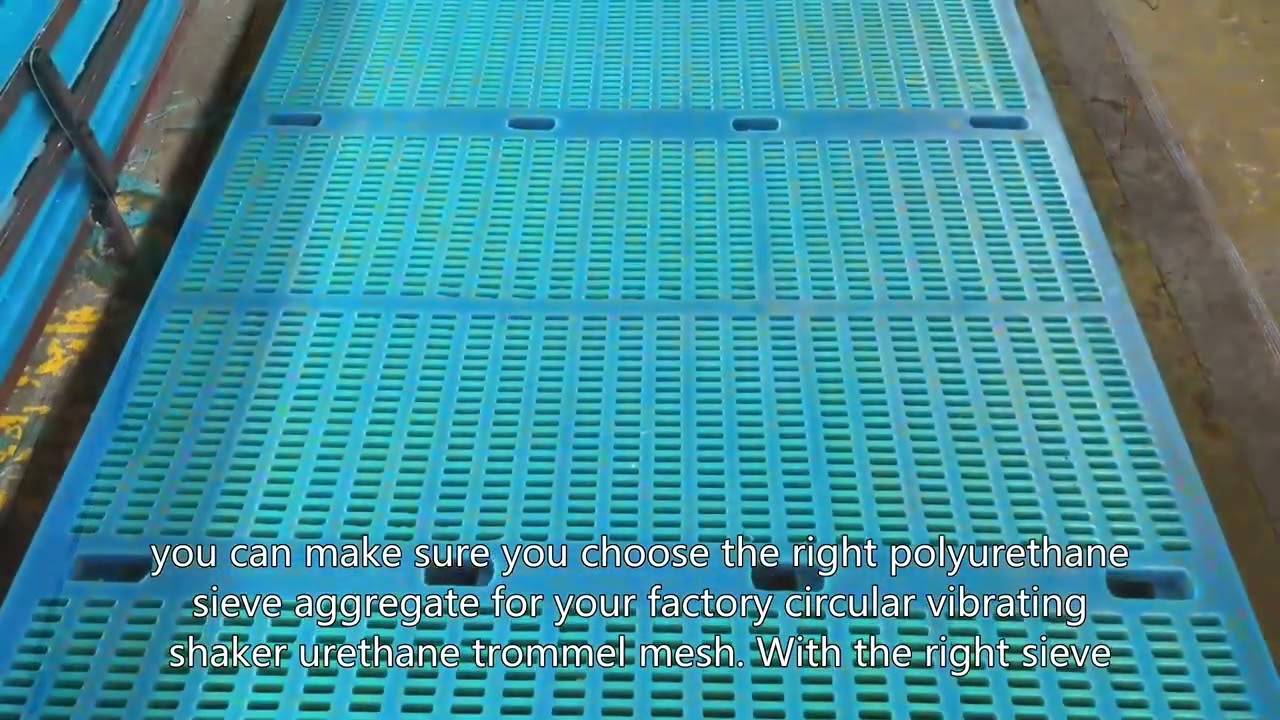

When it comes to choosing the right wholesale screen mesh sizes for your application, there are several factors to consider. One of the most important considerations is the type of material you will be screening. Different materials require different mesh sizes to effectively separate particles. For example, fine mesh sizes are typically used for screening materials such as sand and gravel, while larger mesh sizes are more suitable for screening larger particles like rocks and stones.

Another important factor to consider when choosing wholesale screen mesh sizes is the desired output size of the material. If you are looking to produce a specific size of material, you will need to select a mesh size that is capable of achieving that output. For example, if you are looking to produce fine sand, you will need a mesh size that is capable of separating out the smaller particles.

It is also important to consider the capacity of the vibrating screen when selecting wholesale screen mesh sizes. The capacity of the screen will determine how much material can be processed at a given time. If you are working with a high volume of material, you will need a screen with a larger capacity and a larger mesh size to accommodate the increased throughput.

In addition to material type, output size, and capacity, it is also important to consider the overall quality of the screen mesh. Choosing a reputable supplier of vibrating screen mesh is essential to ensure that you are getting a high-quality product that will perform effectively and last for a long time. Look for suppliers who offer a wide range of mesh sizes and materials to choose from, as well as customization options to meet your specific needs.

When selecting wholesale screen mesh sizes, it is important to consider the overall cost of the product. While it may be tempting to choose the cheapest option available, it is important to remember that quality is key when it comes to vibrating screen mesh. Investing in a high-quality product upfront can save you time and money in the long run by reducing maintenance and replacement costs.

In conclusion, choosing the right wholesale screen mesh sizes for your application is essential to achieving optimal performance and efficiency. Consider factors such as material type, output size, capacity, and overall quality when selecting a supplier. By taking the time to research and choose the right screen mesh sizes, you can ensure that your vibrating screen will effectively separate particles and produce the desired output size for your specific application.