極細篩網,振動篩網孔,振動篩網孔尺寸

超細篩網終極指南:應用與優勢 超細篩網終極指南:應用與優勢 探索振動篩網在工業用途的多功能性 如何為您的專案選擇合適的振動篩網目尺寸 另一個需要考慮的因素是振動篩網中使用的編織類型。不同的編織技術會影響網的強度、靈活性和篩選能力。例如,平紋編織是最常見的,通常可以在強度和開口面積之間提供平衡。另一方面,斜紋編織可以提供更高的開放面積,但可能不太堅固。編織的選擇將取決於您項目的具體要求以及所篩選材料的性質。常見的材料包括以其耐用性和耐腐蝕性而聞名的不銹鋼,以及因其強度和耐磨性而經常使用的高碳鋼。聚氨酯或橡膠等合成材料可用於金屬網不適合的特定應用,例如處理高腐蝕性物質或優先考慮降噪時。仔細考慮。正在處理的材料類型、所需的分離程度、線直徑、編織類型和網的材料都在確定最合適的網尺寸方面發揮作用。考慮這些因素,您可以確保您的振動篩高效運行,隨著時間的推移保持其完整性,並提供專案所需的品質結果。透過正確的篩孔尺寸,您的篩選過程可以實現精度和生產力,從而為您的營運帶來成功的結果。 How to Choose the Right vibrating screen mesh size for Your Project Choosing the right vibrating screen…

超細篩網終極指南:應用與優勢

超細篩網終極指南:應用與優勢

探索振動篩網在工業用途的多功能性

如何為您的專案選擇合適的振動篩網目尺寸

另一個需要考慮的因素是振動篩網中使用的編織類型。不同的編織技術會影響網的強度、靈活性和篩選能力。例如,平紋編織是最常見的,通常可以在強度和開口面積之間提供平衡。另一方面,斜紋編織可以提供更高的開放面積,但可能不太堅固。編織的選擇將取決於您項目的具體要求以及所篩選材料的性質。常見的材料包括以其耐用性和耐腐蝕性而聞名的不銹鋼,以及因其強度和耐磨性而經常使用的高碳鋼。聚氨酯或橡膠等合成材料可用於金屬網不適合的特定應用,例如處理高腐蝕性物質或優先考慮降噪時。仔細考慮。正在處理的材料類型、所需的分離程度、線直徑、編織類型和網的材料都在確定最合適的網尺寸方面發揮作用。考慮這些因素,您可以確保您的振動篩高效運行,隨著時間的推移保持其完整性,並提供專案所需的品質結果。透過正確的篩孔尺寸,您的篩選過程可以實現精度和生產力,從而為您的營運帶來成功的結果。

How to Choose the Right vibrating screen mesh size for Your Project

Choosing the right vibrating screen mesh size is crucial for the efficiency and success of your screening or sifting project. A very fine mesh screen can significantly impact the quality of the material being processed, as well as the longevity and performance of the screen itself. Understanding the various aspects of vibrating screen mesh can help you make an informed decision that will optimize your operation’s output.

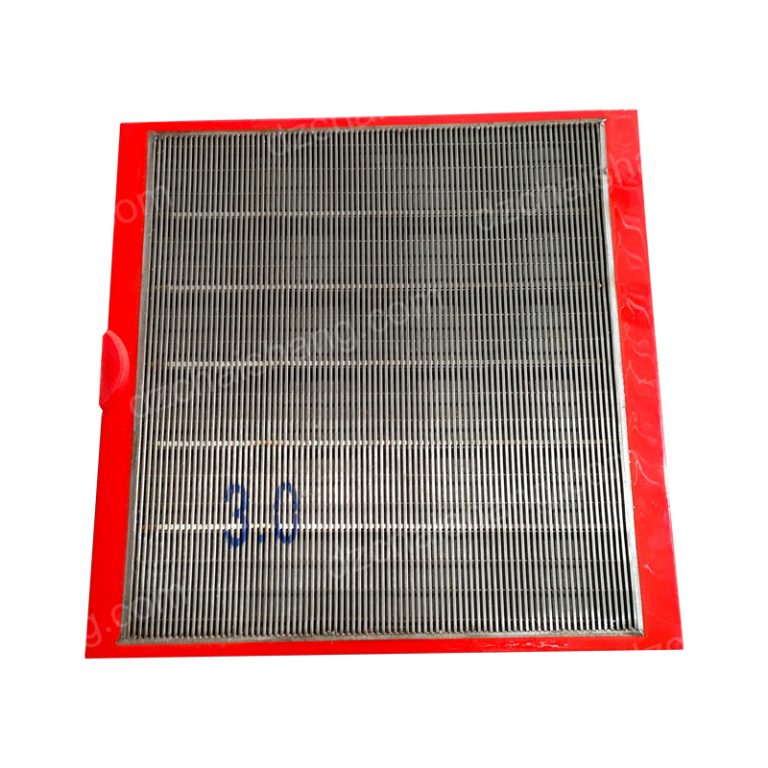

Vibrating screen mesh is the component of the screening machine that is responsible for sorting, separating, and sifting materials. The mesh size refers to the number of openings per linear inch, and it is a critical factor in determining the final product size. A very fine mesh screen, for instance, will have a high number of openings per inch, which allows it to separate smaller particles more effectively.

When selecting a vibrating screen mesh, it is essential to consider the type of material you are processing. Different materials have unique characteristics that can affect how they interact with the mesh. For example, materials that are wet, sticky, or particularly fine may require a different mesh size compared to dry or coarse materials. The goal is to choose a mesh size that allows the material to move freely over the screen without clogging the openings, while still achieving the desired level of separation.

The wire diameter of the mesh also plays a significant role in the screening process. A thicker wire diameter can provide greater strength and durability, which is beneficial for handling heavy or abrasive materials. However, a thicker wire will also reduce the open area of the mesh, potentially limiting the flow of material. Conversely, a thinner wire diameter increases the open area but may be more susceptible to wear and tear. Therefore, it is important to strike a balance between wire diameter and open area to ensure optimal performance.

Another factor to consider is the type of weave used in the vibrating screen mesh. Different weaving techniques can influence the mesh’s strength, flexibility, and screening capabilities. For instance, a plain weave is the most common and typically offers a balance between strength and open area. Twilled weave, on the other hand, can provide a higher open area but may be less robust. The choice of weave will depend on the specific requirements of your project and the nature of the materials being screened.

The material of the vibrating screen mesh itself is another critical consideration. Common materials include stainless steel, which is known for its durability and resistance to corrosion, and high-carbon steel, which is often used for its strength and abrasion resistance. Synthetic materials like polyurethane or rubber can be used for specific applications where metal meshes are not suitable, such as when dealing with highly corrosive substances or when noise reduction is a priority.

In conclusion, selecting the right vibrating screen mesh size for your project involves a careful consideration of various factors. The type of material being processed, the desired level of separation, the wire diameter, the weave type, and the material of the mesh all play a role in determining the most appropriate mesh size. By taking into account these elements, you can ensure that your vibrating screen operates efficiently, maintains its integrity over time, and delivers the quality results your project demands. With the right mesh size, your screening process can achieve precision and productivity, leading to a successful outcome for your operation.