搖床PU精板訂製礦石,直銷搖床人字拖聚氨酯網礦物

礦石直銷中搖床PU精板客製化探索 振動篩 PU 細板的客製化是一個涉及客製化板以滿足採礦作業的特定需求的過程。這可以包括調整板的尺寸、形狀和設計以適應操作中使用的機械。定製過程還包括選擇正確類型的聚氨酯,以確保板材能夠承受採礦環境的特定條件。首先,客製化板材可以顯著提升礦石直銷流程的效率。透過客製化板以適應操作中使用的機械,板可以有效地分離材料,減少廢物量並提高有價值礦物的產量。這可以增加採礦作業的利潤。透過使用專為承受採礦環境特定條件而設計的板材,機器不太可能遭受磨損。這可以減少頻繁維護和更換零件的需要,為採礦作業節省時間和金錢。透過減少礦石直銷過程中產生的廢棄物量,可以最大限度地減少對環境的影響。這在當今世界尤其重要,業界採用永續實踐的壓力越來越大。透過客製化板材以滿足採礦作業的特定需求,板材可以提高流程效率,延長機械壽命,並有助於營運的可持續性。隨著採礦業的不斷發展,振動篩PU精板的客製化很可能成為礦石直銷日益重要的面向。 Shaker PU fine plates, also known as shaker flip flop urethane mesh, are used in the mining industry…

礦石直銷中搖床PU精板客製化探索

振動篩 PU 細板的客製化是一個涉及客製化板以滿足採礦作業的特定需求的過程。這可以包括調整板的尺寸、形狀和設計以適應操作中使用的機械。定製過程還包括選擇正確類型的聚氨酯,以確保板材能夠承受採礦環境的特定條件。首先,客製化板材可以顯著提升礦石直銷流程的效率。透過客製化板以適應操作中使用的機械,板可以有效地分離材料,減少廢物量並提高有價值礦物的產量。這可以增加採礦作業的利潤。透過使用專為承受採礦環境特定條件而設計的板材,機器不太可能遭受磨損。這可以減少頻繁維護和更換零件的需要,為採礦作業節省時間和金錢。透過減少礦石直銷過程中產生的廢棄物量,可以最大限度地減少對環境的影響。這在當今世界尤其重要,業界採用永續實踐的壓力越來越大。透過客製化板材以滿足採礦作業的特定需求,板材可以提高流程效率,延長機械壽命,並有助於營運的可持續性。隨著採礦業的不斷發展,振動篩PU精板的客製化很可能成為礦石直銷日益重要的面向。

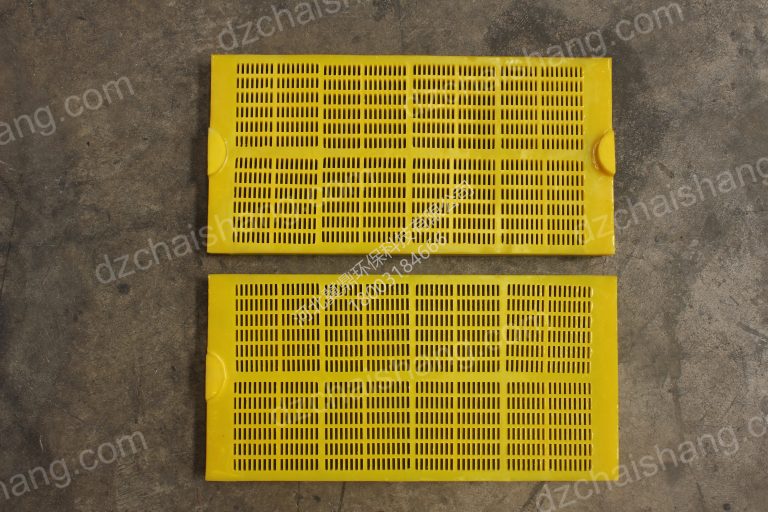

Shaker PU fine plates, also known as shaker flip flop urethane mesh, are used in the mining industry for the separation of materials. These plates are made from polyurethane, a material known for its durability and resistance to wear and tear. The shaker PU fine plates are designed to withstand the harsh conditions of the mining environment, making them an ideal choice for ore direct selling.

The benefits of customizing shaker PU fine plates are numerous. Firstly, customized plates can significantly enhance the efficiency of the ore direct selling process. By tailoring the plates to fit the machinery used in the operation, the plates can effectively separate the materials, reducing the amount of waste and increasing the yield of valuable minerals. This can lead to increased profits for the mining operation.

Secondly, customized shaker PU fine plates can improve the longevity of the machinery used in the operation. By using plates that are designed to withstand the specific conditions of the mining environment, the machinery is less likely to suffer from wear and tear. This can reduce the need for frequent maintenance and replacement of parts, saving time and money for the mining operation.

Lastly, the customization of shaker PU fine plates can contribute to the sustainability of the mining operation. By reducing the amount of waste produced in the ore direct selling process, the operation can minimize its environmental impact. This is particularly important in today’s world, where there is increasing pressure on industries to adopt sustainable practices.

In conclusion, the customization of shaker PU fine plates plays a crucial role in the ore direct selling process. By tailoring the plates to meet the specific needs of a mining operation, the plates can enhance the efficiency of the process, improve the longevity of the machinery, and contribute to the sustainability of the operation. As the mining industry continues to evolve, the customization of shaker PU fine plates is likely to become an increasingly important aspect of ore direct selling.