採石場篩網供應商,篩網出售,篩網

探索高品質採石場篩網對高效物料分選的好處 根據您的篩選需求選擇合適篩網的終極指南 首先,重要的是要了解篩網有不同類型,每種類型都有特定的用途。最常見的類型包括編織金屬絲網、聚氨酯篩網和穿孔金屬篩網。編織金屬絲網以其高拉伸強度和耐用性而聞名,使其成為重型篩選任務的理想選擇。另一方面,聚氨酯篩網以其優異的耐磨性和柔韌性而聞名,這使其適合篩分磨蝕性材料。穿孔金屬篩網的特點是結構堅固、效率高,非常適合需要高精度的應用。篩網的目數是指每英吋的孔數。目數越高,孔徑越小,過濾越細;目數越低,孔徑越大,過濾越粗。因此,如果篩選精細物料,應選擇目數較高的篩網。相反,對於較粗的材料,具有較低目數的篩網會更合適。例如,如果篩網要在腐蝕環境中使用,則應謹慎選擇由耐腐蝕材料製成的篩網,例如不銹鋼或聚氨酯。同樣,如果篩網要在高溫環境下使用,建議選擇耐熱材料製成的篩網。可靠的供應商應該能夠提供滿足您特定需求的高品質篩網。他們還應該提供卓越的客戶服務,包括及時交貨和售後支援。建議選擇在市場上享有良好聲譽且已從事相當長一段時間的供應商。 、被篩物料的大小、環境條件、供應商的選擇。考慮這些因素,您可以確保您選擇的篩網不僅滿足您的篩分需求,而且還具有耐用性和效率。請記住,正確的篩網可以顯著增強您的篩選過程,從而提高生產力並節省成本。 The Ultimate Guide to Choosing the Right screen mesh for Your Screening Needs Screen mesh is an essential…

探索高品質採石場篩網對高效物料分選的好處

根據您的篩選需求選擇合適篩網的終極指南

首先,重要的是要了解篩網有不同類型,每種類型都有特定的用途。最常見的類型包括編織金屬絲網、聚氨酯篩網和穿孔金屬篩網。編織金屬絲網以其高拉伸強度和耐用性而聞名,使其成為重型篩選任務的理想選擇。另一方面,聚氨酯篩網以其優異的耐磨性和柔韌性而聞名,這使其適合篩分磨蝕性材料。穿孔金屬篩網的特點是結構堅固、效率高,非常適合需要高精度的應用。篩網的目數是指每英吋的孔數。目數越高,孔徑越小,過濾越細;目數越低,孔徑越大,過濾越粗。因此,如果篩選精細物料,應選擇目數較高的篩網。相反,對於較粗的材料,具有較低目數的篩網會更合適。例如,如果篩網要在腐蝕環境中使用,則應謹慎選擇由耐腐蝕材料製成的篩網,例如不銹鋼或聚氨酯。同樣,如果篩網要在高溫環境下使用,建議選擇耐熱材料製成的篩網。可靠的供應商應該能夠提供滿足您特定需求的高品質篩網。他們還應該提供卓越的客戶服務,包括及時交貨和售後支援。建議選擇在市場上享有良好聲譽且已從事相當長一段時間的供應商。 、被篩物料的大小、環境條件、供應商的選擇。考慮這些因素,您可以確保您選擇的篩網不僅滿足您的篩分需求,而且還具有耐用性和效率。請記住,正確的篩網可以顯著增強您的篩選過程,從而提高生產力並節省成本。

The Ultimate Guide to Choosing the Right screen mesh for Your Screening Needs

Screen mesh is an essential component in various industries, particularly in quarrying and mining. It plays a crucial role in sieving and filtering different types of materials, such as stones, sand, and other minerals. With the increasing demand for high-quality screen mesh, numerous quarry screen mesh suppliers have emerged in the market, offering a wide range of screen mesh for sale. However, choosing the right screen mesh for your screening needs can be a daunting task, given the myriad of options available. This article serves as an ultimate guide to help you make an informed decision.

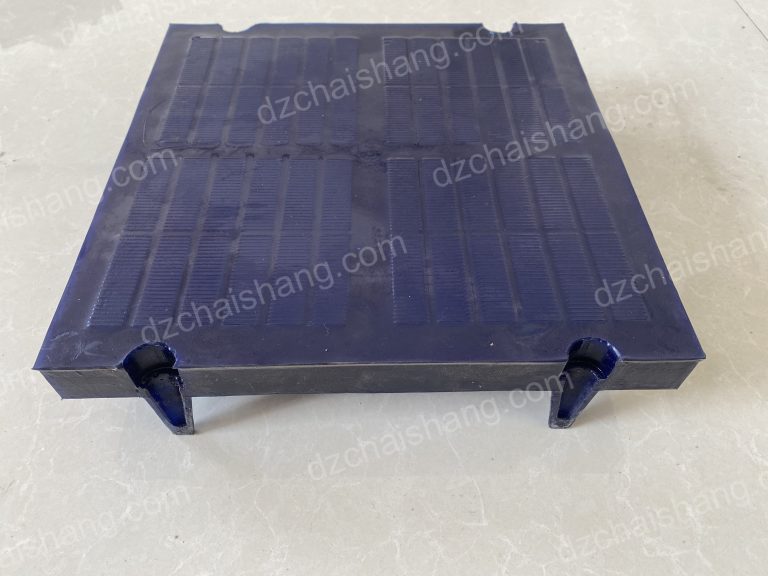

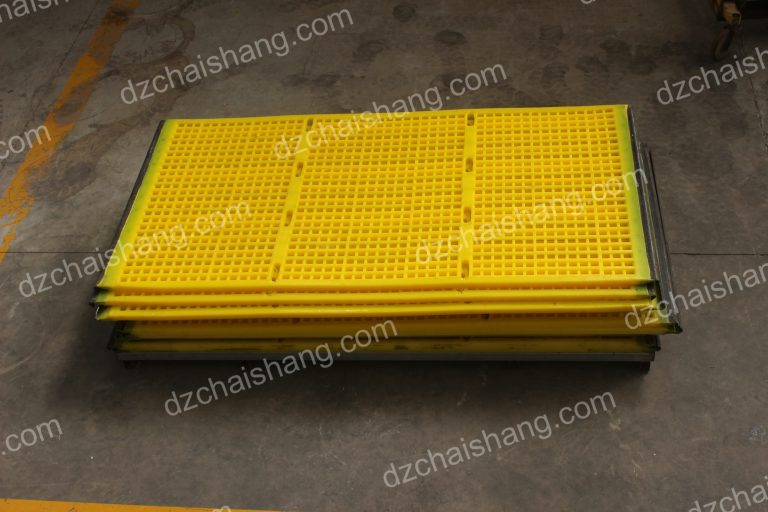

Firstly, it is important to understand that screen mesh comes in different types, each designed for a specific purpose. The most common types include Woven wire mesh, polyurethane screen mesh, and perforated metal screen mesh. Woven wire mesh is known for its high tensile strength and durability, making it ideal for heavy-duty screening tasks. Polyurethane screen mesh, on the other hand, is renowned for its excellent abrasion resistance and flexibility, which makes it suitable for screening abrasive materials. Perforated metal screen mesh is characterized by its robust structure and high efficiency, perfect for applications that require high precision.

When choosing a screen mesh, the size of the material to be screened is a critical factor to consider. The screen mesh size refers to the number of openings per inch. A higher mesh number means smaller openings and finer filtration, while a lower mesh number indicates larger openings and coarser filtration. Therefore, if you are screening fine materials, you should opt for a screen mesh with a higher mesh number. Conversely, for coarser materials, a screen mesh with a lower mesh number would be more appropriate.

The environmental conditions in which the screen mesh will be used should also be taken into account. For instance, if the screen mesh is to be used in a corrosive environment, it would be prudent to choose a screen mesh made of materials that are resistant to corrosion, such as stainless steel or polyurethane. Similarly, if the screen mesh is to be used in a high-temperature environment, it would be advisable to choose a screen mesh made of heat-resistant materials.

The choice of quarry screen mesh suppliers is equally important. A reliable supplier should be able to provide high-quality screen mesh that meets your specific needs. They should also offer excellent customer service, including timely delivery and after-sales support. It is advisable to choose suppliers who have a good reputation in the market and have been in the business for a considerable period.

In conclusion, choosing the right screen mesh for your screening needs requires careful consideration of various factors, including the type of screen mesh, the size of the material to be screened, the environmental conditions, and the choice of suppliers. By taking these factors into account, you can ensure that you choose a screen mesh that not only meets your screening needs but also offers durability and efficiency. Remember, the right screen mesh can significantly enhance your screening process, leading to increased productivity and cost savings.