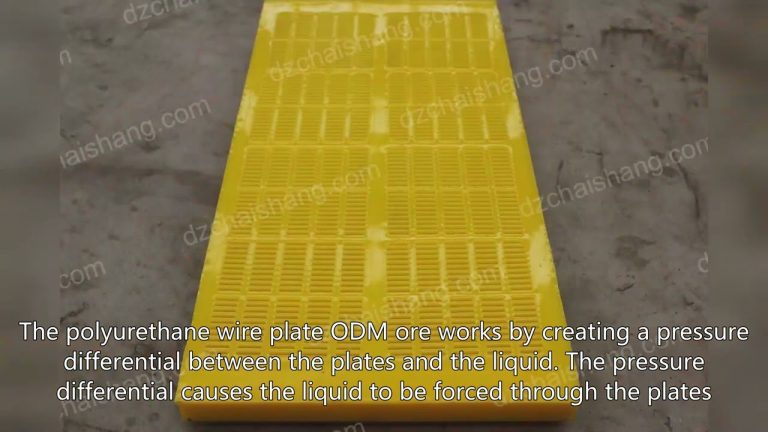

PU篩網取代不銹鋼絲網

升級為不鏽鋼絲網取代 PU 篩網的好處 除了其功能優勢外,不鏽鋼絲網還有助於環境的永續發展。作為一種可回收材料,與 PU 等合成材料相比,不銹鋼對環境的影響較小。透過選擇不銹鋼絲網,各行業可以減少碳足跡並促進更永續的運作。不銹鋼無孔,不會滋生細菌,更容易清潔消毒。此特性有助於防止污染並確保產品的安全和品質。延長的使用壽命、減少的維護要求和提高的效率有助於降低總擁有成本。此外,不銹鋼絲網的多功能性使其適用於廣泛的應用,進一步提高了其作為 PU 篩網替代品的價值。提高工業篩選操作的性能和成本效益。其耐用性、精度、耐熱性、可持續性和衛生特性使其成為尋求改進篩選流程並獲得更好結果的行業的理想選擇。隨著各行業不斷尋求將效率與永續性結合的解決方案,不銹鋼絲網作為傳統 PU 篩網的卓越替代品脫穎而出。 stainless steel wire mesh offers a range of benefits that make it…

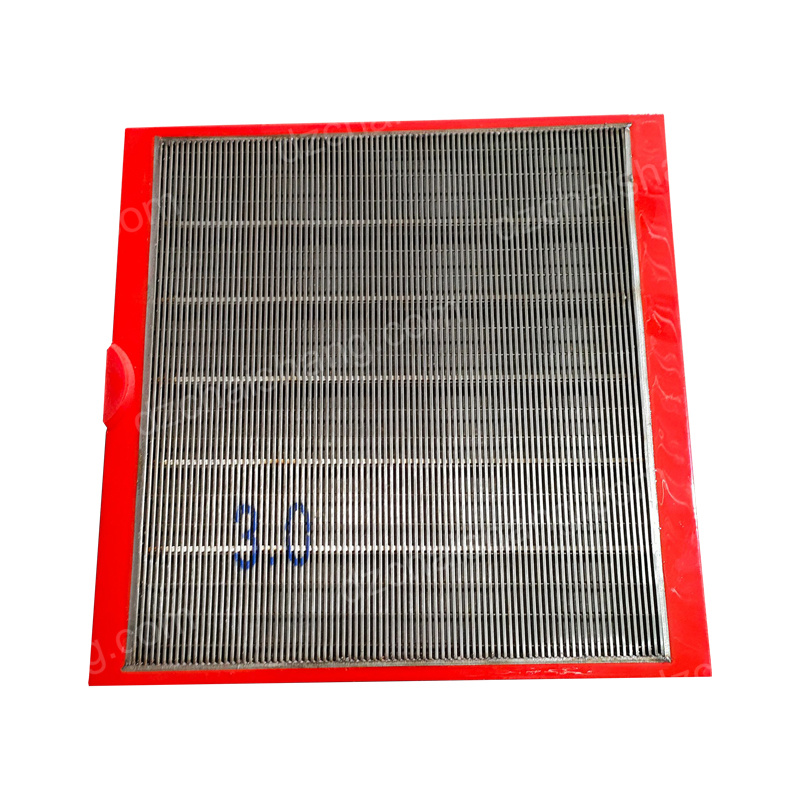

升級為不鏽鋼絲網取代 PU 篩網的好處

除了其功能優勢外,不鏽鋼絲網還有助於環境的永續發展。作為一種可回收材料,與 PU 等合成材料相比,不銹鋼對環境的影響較小。透過選擇不銹鋼絲網,各行業可以減少碳足跡並促進更永續的運作。不銹鋼無孔,不會滋生細菌,更容易清潔消毒。此特性有助於防止污染並確保產品的安全和品質。延長的使用壽命、減少的維護要求和提高的效率有助於降低總擁有成本。此外,不銹鋼絲網的多功能性使其適用於廣泛的應用,進一步提高了其作為 PU 篩網替代品的價值。提高工業篩選操作的性能和成本效益。其耐用性、精度、耐熱性、可持續性和衛生特性使其成為尋求改進篩選流程並獲得更好結果的行業的理想選擇。隨著各行業不斷尋求將效率與永續性結合的解決方案,不銹鋼絲網作為傳統 PU 篩網的卓越替代品脫穎而出。

Another significant benefit of upgrading to stainless steel wire mesh is its ability to provide more precise and consistent screening results. Stainless steel wire mesh can be manufactured with uniform and tight tolerances, ensuring consistent aperture sizes throughout the mesh. This level of precision is crucial in industries where particle size and separation accuracy are critical, such as in pharmaceuticals, food processing, and mining. The consistent aperture sizes help in achieving more accurate screening and classification, leading to improved product quality and reduced material wastage.

Furthermore, stainless steel wire mesh offers better heat resistance compared to PU screening mesh. This makes it suitable for applications involving high temperatures, where PU mesh might degrade or melt. The heat resistance of stainless steel allows it to maintain its structural integrity and performance even under extreme temperature conditions, expanding its applicability across various industries.

In addition to its functional advantages, stainless steel wire mesh also contributes to environmental sustainability. Being a recyclable material, stainless steel has a lower environmental impact compared to synthetic materials like PU. By choosing stainless steel wire mesh, industries can reduce their carbon footprint and promote a more sustainable operation.

The transition to stainless steel wire mesh also brings about improved hygiene standards, particularly in industries where cleanliness is paramount, such as in food and beverage processing. Stainless steel is non-porous and does not harbor bacteria, making it easier to clean and sanitize. This property helps in preventing contamination and ensuring the safety and quality of the products.

While the initial cost of stainless steel wire mesh might be higher than that of PU screening mesh, the long-term benefits it offers make it a cost-effective choice. The extended lifespan, reduced maintenance requirements, and improved efficiency contribute to a lower total cost of ownership. Additionally, the versatility of stainless steel wire mesh makes it suitable for a wide range of applications, further enhancing its value as a replacement for PU screening mesh.

In conclusion, upgrading to stainless steel wire mesh for PU screening mesh replacement offers numerous benefits that can significantly enhance the performance and cost-effectiveness of industrial screening operations. Its durability, precision, heat resistance, sustainability, and hygiene properties make it an ideal choice for industries looking to improve their screening processes and achieve better results. As industries continue to seek solutions that combine efficiency with sustainability, stainless steel wire mesh stands out as a superior alternative to traditional PU screening mesh.