聚氨酯篩板,聚氨酯篩板,pu篩板

聚氨酯篩板在採礦作業中的優點與應用 聚氨酯篩網與傳統篩網材料的比較 提高耐用性和效率的 PU 螢幕板保養技巧 維護 PU 篩板的另一個重要方面是在安裝和拆卸過程中小心處理它們。聚氨酯雖然耐用,但仍容易受到尖銳物體或粗暴搬運的損壞。安裝或拆卸面板時使用適當的工具和技術,以防止撕裂或其他損壞。此外,確保面板根據製造商的規格正確對齊和張緊。安裝不當會導致不均勻磨損並降低篩分性能。負載能力、振動頻率和材料特性等因素會影響面板的磨損和性能。將這些參數調整到最佳水平可以幫助最大限度地減少面板上的壓力並延長其使用壽命。根據篩分過程的具體要求定期檢查和調整操作設定可以顯著提高 PU 篩板的耐用性和效率。操作條件的最佳化。透過遵循這些維護技巧,使用者可以提高聚氨酯篩板的耐用性和效率,確保它們在篩分應用中繼續提供可靠的性能。 polyurethane screen panels, also known as PU screen panels, have become increasingly…

聚氨酯篩板在採礦作業中的優點與應用

聚氨酯篩網與傳統篩網材料的比較

提高耐用性和效率的 PU 螢幕板保養技巧

維護 PU 篩板的另一個重要方面是在安裝和拆卸過程中小心處理它們。聚氨酯雖然耐用,但仍容易受到尖銳物體或粗暴搬運的損壞。安裝或拆卸面板時使用適當的工具和技術,以防止撕裂或其他損壞。此外,確保面板根據製造商的規格正確對齊和張緊。安裝不當會導致不均勻磨損並降低篩分性能。負載能力、振動頻率和材料特性等因素會影響面板的磨損和性能。將這些參數調整到最佳水平可以幫助最大限度地減少面板上的壓力並延長其使用壽命。根據篩分過程的具體要求定期檢查和調整操作設定可以顯著提高 PU 篩板的耐用性和效率。操作條件的最佳化。透過遵循這些維護技巧,使用者可以提高聚氨酯篩板的耐用性和效率,確保它們在篩分應用中繼續提供可靠的性能。

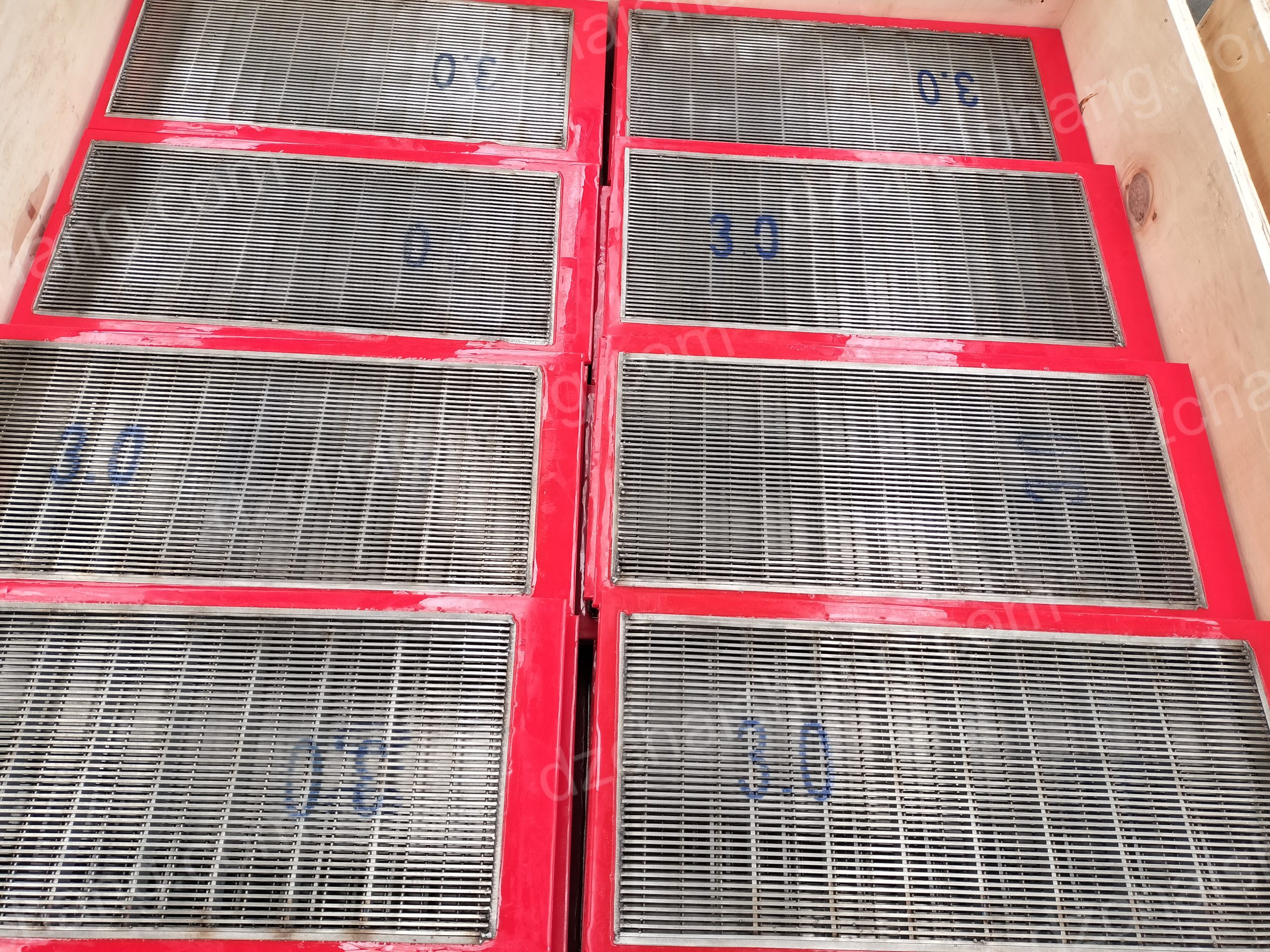

polyurethane screen panels, also known as PU screen panels, have become increasingly popular in various industries for their superior performance in screening applications. These panels are made from polyurethane, a versatile polymer that offers excellent resistance to wear, abrasion, and tearing. As a result, polyurethane screens provide a longer service life compared to traditional screening materials such as wire mesh and perforated metal.

One of the key advantages of polyurethane screen panels is their ability to reduce noise levels during operation. Unlike metal screens, which can produce significant noise when particles strike the surface, polyurethane screens absorb the impact, leading to quieter operation. This not only improves the working environment but also complies with noise regulations in many industries.

Furthermore, polyurethane screens offer superior flexibility, which enhances their efficiency in screening applications. The elasticity of the material allows the screen to flex and prevent blinding and pegging, common issues with rigid screening materials. This flexibility ensures that the screen maintains a high screening efficiency, even with difficult-to-screen materials or in wet conditions.

In terms of maintenance, polyurethane screens require less frequent replacement due to their durability. This reduces downtime and maintenance costs, contributing to overall operational efficiency. Additionally, the lightweight nature of polyurethane makes these screens easier to handle and install, further reducing labor costs and enhancing safety during maintenance.

Another significant benefit of polyurethane screens is their environmental impact. As these screens last longer, they reduce the need for frequent replacements, thereby minimizing waste. Moreover, polyurethane is a recyclable material, which supports sustainability initiatives in various industries.

Comparatively, traditional screening materials such as wire mesh and perforated metal have limitations that polyurethane screens address. Wire mesh screens, for example, are prone to corrosion and wear, especially in wet or corrosive environments. This can lead to frequent replacements and increased maintenance costs. Perforated metal screens, on the other hand, are rigid and can suffer from blinding, where particles get stuck in the holes, reducing screening efficiency.

Additionally, both wire mesh and perforated metal screens are heavier than polyurethane screens, making them more challenging to handle and install. This not only increases labor costs but also poses a higher risk of injury during maintenance.

In conclusion, polyurethane screen panels offer a range of benefits over traditional screening materials, making them a preferred choice in many industries. Their durability, noise reduction capabilities, flexibility, and environmental friendliness contribute to their growing popularity. While wire mesh and perforated metal screens have been widely used in the past, the advantages of polyurethane screens are leading to a shift in preference towards this innovative material. As industries continue to seek efficient and cost-effective solutions, polyurethane screens are likely to become even more prevalent in screening applications.

Maintenance Tips For pu screen Panels To Enhance Durability And Efficiency

Polyurethane screen panels, commonly referred to as PU screen panels, are widely used in the mining and aggregate industries for their durability and efficiency in separating and sizing various materials. These panels are favored for their ability to reduce noise and their resistance to wear and tear compared to other screening materials. However, to ensure that they continue to function optimally and last longer, proper maintenance is crucial.

One of the primary steps in maintaining PU screen panels is regular inspections. It is essential to check these panels frequently for any signs of wear or damage, such as tears, holes, or disconnections from the frame. Early detection of these issues allows for timely repairs or replacements, preventing further damage and potential operational disruptions. During inspections, it is also important to ensure that all fastenings are secure, as loose panels can lead to inefficient screening and increased wear.

Cleaning the PU screen panels is another vital maintenance practice. Over time, panels can accumulate dust, particles, and other debris that can clog the screen openings and reduce screening efficiency. To clean the panels, use low-pressure water spray to remove any surface dirt and debris. Avoid using high-pressure water or harsh chemicals, as these can damage the polyurethane material. Ensuring the panels are clean not only enhances their efficiency but also contributes to a longer service life.

Proper storage of PU screen panels is also crucial, especially when they are not in use. Store the panels in a dry, cool place away from direct sunlight and extreme temperatures, as exposure to such conditions can cause the polyurethane to degrade or deform. Stacking the panels flat and avoiding placing heavy objects on top of them will help maintain their shape and integrity.

Another important aspect of maintaining PU screen panels is handling them with care during installation and removal. Polyurethane, while durable, can still be susceptible to damage from sharp objects or rough handling. Use appropriate tools and techniques when installing or removing the panels to prevent tearing or other damage. Additionally, ensure that the panels are correctly aligned and tensioned according to the manufacturer’s specifications. Improper installation can lead to uneven wear and reduced screening performance.

Lastly, consider the operating conditions in which the PU screen panels are used. Factors such as load capacity, vibration frequency, and material characteristics can impact the wear and performance of the panels. Adjusting these parameters to optimal levels can help minimize stress on the panels and extend their lifespan. Regularly reviewing and adjusting the operational settings based on the specific requirements of the screening process can contribute significantly to the durability and efficiency of PU screen panels.

In conclusion, maintaining PU screen panels involves a combination of regular inspections, proper cleaning, careful handling, appropriate storage, and optimization of operating conditions. By adhering to these maintenance tips, users can enhance the durability and efficiency of their polyurethane screen panels, ensuring they continue to provide reliable performance in their screening applications.