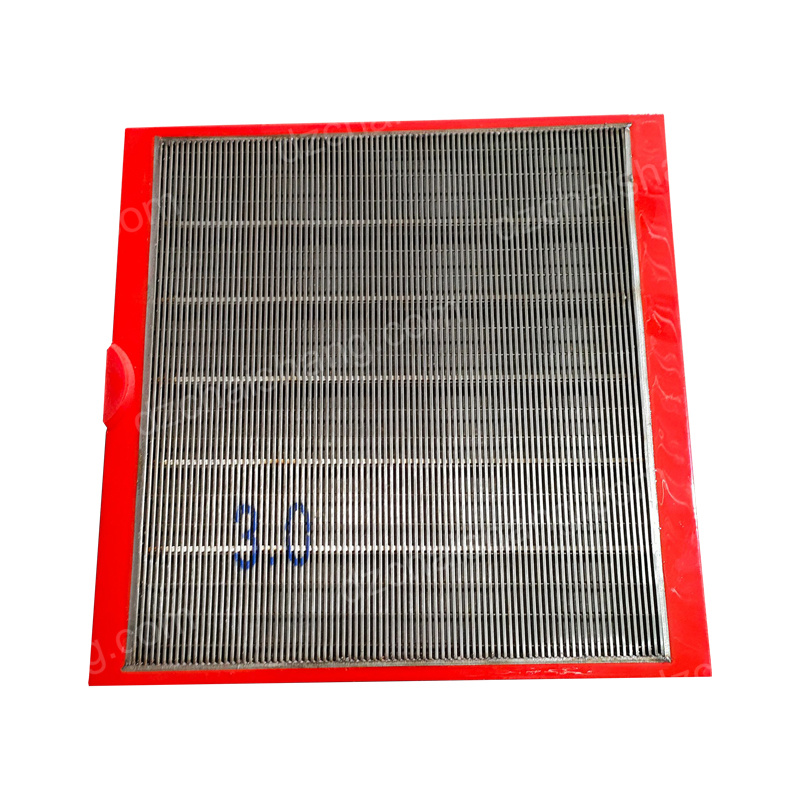

聚氨酯礦用篩網、聚氨酯組合篩網

聚氨酯礦篩網在現代採礦作業中的優勢 維護與耐用性:聚氨酯模組篩網的比較分析 聚氨酯篩網技術創新,提高選礦效率 用於提高選礦效率的聚氨酯篩網技術創新 採礦業一直在尋求更有效率、耐用且更具成本效益的選礦解決方案。在眾多進步中,聚氨酯篩網技術的發展是一項重大飛躍。聚氨酯採礦篩網和模組化篩網徹底改變了礦物加工方式,與金屬絲網和鋼等傳統篩分材料相比,具有無與倫比的優勢。本文深入探討了聚氨酯篩網技術的創新以及它們如何有助於提高選礦效率。 。與金屬同類產品不同,這些篩網不易生鏽或腐蝕,因此非常適合濕式或乾式篩分應用。聚氨酯固有的柔韌性使這些螢幕能夠更好地吸收衝擊力,減少破損的可能性並延長其使用壽命。這種耐用性可以為採礦作業節省大量成本,因為頻繁更換的需求大大減少。聚氨酯模組化篩網尤其反映了這種適應性。這些篩網由單獨的模組組成,可以輕鬆更換或重新排列,從而可以根據特定的選礦要求定制篩分解決方案。這種模組化不僅有利於快速、輕鬆的維護,而且使採礦作業能夠適應不斷變化的加工需求,而無需完全更換篩網。尺寸和形狀的篩網。這種客製化功能可以優化篩選效率,確保根據尺寸準確分離礦物。分離的精確性最大限度地減少了篩上料流中的細料和篩下料流中的粗料的出現,從而提高了選礦作業的整體效率。助於更安全、更有效率地進行選礦。該材料的抑制噪音的能力對於採礦作業特別有益,因為噪音水平可能對工人造成健康風險。這項功能,再加上與聚氨酯篩網相關的維護和停機時間的減少,強調了該技術不僅對運營效率而且對工作場所安全的貢獻。考慮了環境因素螢幕技術。該材料的使用壽命和可回收性符合採礦業對永續發展日益增長的承諾。透過減少篩網更換頻率並選擇可回收材料,採礦作業可以最大限度地減少環境足跡。聚氨酯礦用篩網和模組化篩網的耐用性、適應性和環境效益在業界樹立了新標準。隨著採礦作業不斷尋求更有效率、更永續的解決方案,聚氨酯篩網技術在提高選礦效率方面的作用不容小覷。看來,選礦的未來將越來越依賴聚氨酯篩網技術帶來的創新。 Another advantage of polyurethane screens is their resistance to environmental factors such as corrosion, moisture, and…

聚氨酯礦篩網在現代採礦作業中的優勢

維護與耐用性:聚氨酯模組篩網的比較分析

聚氨酯篩網技術創新,提高選礦效率

用於提高選礦效率的聚氨酯篩網技術創新

採礦業一直在尋求更有效率、耐用且更具成本效益的選礦解決方案。在眾多進步中,聚氨酯篩網技術的發展是一項重大飛躍。聚氨酯採礦篩網和模組化篩網徹底改變了礦物加工方式,與金屬絲網和鋼等傳統篩分材料相比,具有無與倫比的優勢。本文深入探討了聚氨酯篩網技術的創新以及它們如何有助於提高選礦效率。 。與金屬同類產品不同,這些篩網不易生鏽或腐蝕,因此非常適合濕式或乾式篩分應用。聚氨酯固有的柔韌性使這些螢幕能夠更好地吸收衝擊力,減少破損的可能性並延長其使用壽命。這種耐用性可以為採礦作業節省大量成本,因為頻繁更換的需求大大減少。聚氨酯模組化篩網尤其反映了這種適應性。這些篩網由單獨的模組組成,可以輕鬆更換或重新排列,從而可以根據特定的選礦要求定制篩分解決方案。這種模組化不僅有利於快速、輕鬆的維護,而且使採礦作業能夠適應不斷變化的加工需求,而無需完全更換篩網。尺寸和形狀的篩網。這種客製化功能可以優化篩選效率,確保根據尺寸準確分離礦物。分離的精確性最大限度地減少了篩上料流中的細料和篩下料流中的粗料的出現,從而提高了選礦作業的整體效率。助於更安全、更有效率地進行選礦。該材料的抑制噪音的能力對於採礦作業特別有益,因為噪音水平可能對工人造成健康風險。這項功能,再加上與聚氨酯篩網相關的維護和停機時間的減少,強調了該技術不僅對運營效率而且對工作場所安全的貢獻。考慮了環境因素螢幕技術。該材料的使用壽命和可回收性符合採礦業對永續發展日益增長的承諾。透過減少篩網更換頻率並選擇可回收材料,採礦作業可以最大限度地減少環境足跡。聚氨酯礦用篩網和模組化篩網的耐用性、適應性和環境效益在業界樹立了新標準。隨著採礦作業不斷尋求更有效率、更永續的解決方案,聚氨酯篩網技術在提高選礦效率方面的作用不容小覷。看來,選礦的未來將越來越依賴聚氨酯篩網技術帶來的創新。

Another advantage of polyurethane screens is their resistance to environmental factors such as corrosion, moisture, and temperature variations. In contrast to steel screens that can rust and degrade over time, especially in wet or humid conditions, polyurethane screens are impervious to such elements, ensuring consistent performance and longevity. This resistance to corrosion also means that polyurethane screens are less likely to contaminate the screened materials with rust particles, which is particularly important in applications where material purity is paramount.

The modular design of polyurethane screens offers additional maintenance benefits. Individual panels or modules can be easily replaced without the need to change the entire screen, making repairs quick and cost-effective. This modularity also allows for customized configurations to meet specific screening requirements, enhancing the overall efficiency of the operation.

Furthermore, the lightweight nature of polyurethane screens compared to their metal counterparts facilitates easier handling and installation. This not only reduces the risk of injury during maintenance tasks but also lowers the labor costs associated with screen replacements and repairs.

In conclusion, polyurethane modular screens represent a significant advancement in mining technology, offering superior durability and reduced maintenance requirements. Their ability to withstand abrasive materials, resist environmental degradation, and facilitate easy repairs makes them an invaluable asset in the mining industry. As operations continue to seek ways to improve efficiency and reduce costs, the adoption of polyurethane screens is likely to become even more widespread, solidifying their status as a key component in the future of mining.

Innovations in polyurethane screen Technology for Enhanced Mineral Processing Efficiency

Innovations in Polyurethane Screen Technology for Enhanced Mineral Processing Efficiency

The mining industry is perpetually on the quest for more efficient, durable, and cost-effective solutions for mineral processing. Among the myriad of advancements, the development of polyurethane screen technology stands out as a significant leap forward. polyurethane mining screens and modular screens have revolutionized the way minerals are processed, offering unparalleled benefits over traditional screening materials like wire mesh and steel. This article delves into the innovations in polyurethane screen technology and how they contribute to enhanced mineral processing efficiency.

Polyurethane screens, known for their exceptional durability and resistance to wear and tear, have become increasingly popular in the mining sector. Unlike their metal counterparts, these screens are not prone to rusting or corrosion, making them ideal for wet or dry screening applications. The inherent flexibility of polyurethane allows these screens to absorb impact better, reducing the likelihood of breakage and prolonging their service life. This durability translates into significant cost savings for mining operations, as the need for frequent replacements is drastically reduced.

Moreover, the adaptability of polyurethane to various screening applications is a testament to its versatility. Polyurethane modular screens, in particular, exemplify this adaptability. These screens are composed of individual modules that can be easily replaced or rearranged, allowing for customized screening solutions tailored to specific mineral processing requirements. This modularity not only facilitates quick and easy maintenance but also enables mining operations to adapt to changing processing demands without the need for complete screen replacement.

Another noteworthy innovation in polyurethane screen technology is the development of screens with varying aperture sizes and shapes. This customization capability allows for the optimization of screening efficiency, ensuring that minerals are accurately separated according to size. The precision in separation minimizes the occurrence of fine material in the oversize stream and coarse material in the undersize stream, thereby enhancing the overall efficiency of the mineral processing operation.

Furthermore, the noise reduction properties of polyurethane screens contribute to a safer and more comfortable working environment. The material’s ability to dampen noise is particularly beneficial in mining operations where noise levels can pose health risks to workers. This feature, coupled with the reduced maintenance and downtime associated with polyurethane screens, underscores the technology’s contribution to not only operational efficiency but also workplace safety.

In addition to these benefits, environmental considerations have also been taken into account in the development of polyurethane screen technology. The material’s longevity and recyclability align with the mining industry’s growing commitment to sustainability. By reducing the frequency of screen replacements and opting for a recyclable material, mining operations can minimize their environmental footprint.

In conclusion, the innovations in polyurethane screen technology represent a significant advancement in mineral processing efficiency. The durability, adaptability, and environmental benefits of polyurethane mining screens and modular screens have set a new standard in the industry. As mining operations continue to seek more efficient and sustainable solutions, the role of polyurethane screen technology in enhancing mineral processing efficiency cannot be overstated. The future of mineral processing, it seems, will be increasingly reliant on the innovations brought about by polyurethane screen technology.