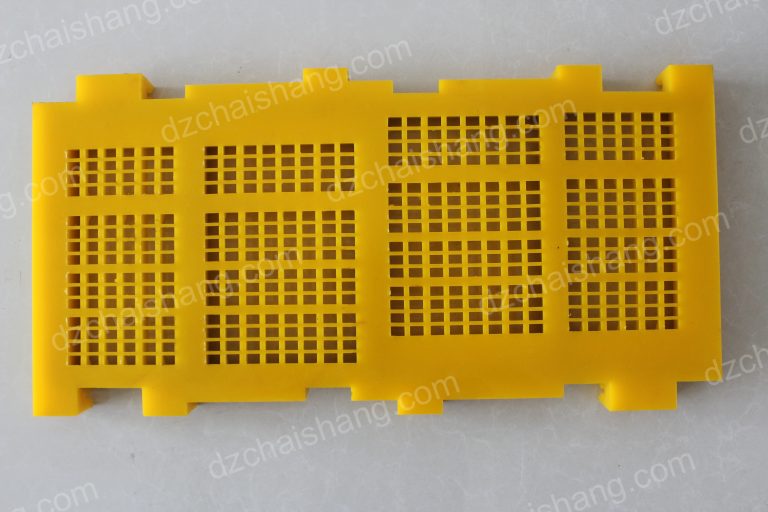

礦用振動聚氨酯篩網,礦用篩網

在採礦作業中使用聚氨酯篩網的好處 如何正確維護及延長礦用振動篩的使用壽命 礦用振動篩是採礦業中必不可少的設備,因為它們用於根據物料的尺寸來分離物料。這些篩網通常由聚氨酯製成,這是一種耐用材料,可以承受採礦作業的惡劣條件。正確維護採礦振動篩對於確保其使用壽命和效率至關重要。在本文中,我們將討論如何正確維護和延長礦用振動篩使用壽命的一些技巧。隨著時間的推移,灰塵、污垢和其他碎屑會積聚在螢幕表面,從而影響其性能。若要清潔螢幕,請使用軟刷或軟布清除任何堆積物。避免使用刺激性化學物質或研磨材料,因為它們會損壞聚氨酯材料。定期清潔有助於防止堵塞並確保螢幕平穩運行。檢查是否有撕裂、孔洞或其他可能影響螢幕表現的缺陷。如果發現任何損壞,應立即修理或更換,以防止進一步惡化。定期檢查將有助於及早發現潛在問題,並防止日後進行昂貴的維修或更換。不使用時,螢幕應存放在乾燥、陰涼的地方,以防止潮濕或極端溫度造成損壞。避免將螢幕存放在陽光直射或靠近熱源的地方,因為這可能會導致聚氨酯材料降解。正確的存放將有助於延長篩子的使用壽命,並確保其更長時間地保持良好狀態。避免使篩網超載超出其容量的材料,因為這可能會導致過度磨損和損壞。請遵循製造商的螢幕操作指南,並確保在規定的限制內使用它。正確使用將有助於防止過早磨損並延長篩網的使用壽命。透過遵循這些提示,您可以正確維護螢幕並延長其使用壽命。請記住定期清潔螢幕、檢查其是否損壞、正確存放並正確使用,以防止過早磨損並確保最佳性能。透過適當的維護,您的採礦振動篩將在未來幾年繼續有效率且有效地運作。 Furthermore, polyurethane screens are lightweight and easy to install, reducing labor costs and installation time. Their lightweight construction also…

在採礦作業中使用聚氨酯篩網的好處

如何正確維護及延長礦用振動篩的使用壽命

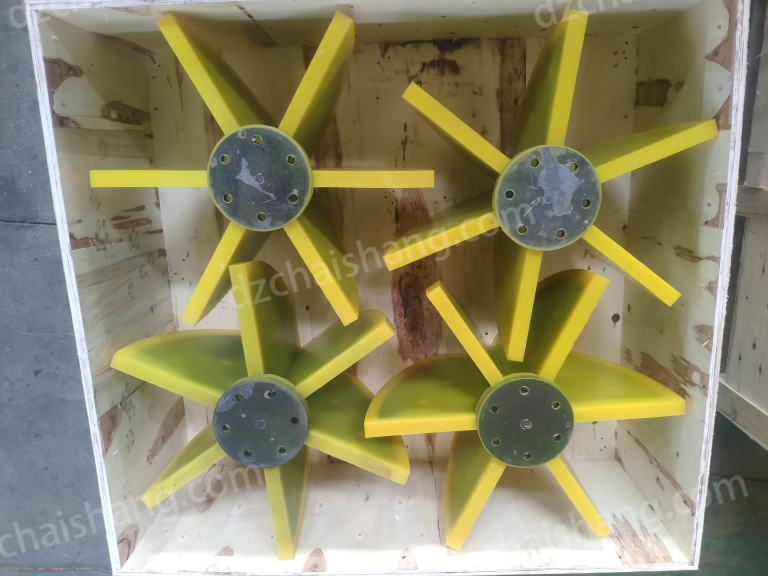

Furthermore, polyurethane screens are lightweight and easy to install, reducing labor costs and installation time. Their lightweight construction also makes them easier to handle and transport, contributing to overall operational efficiency. Additionally, polyurethane screens are corrosion-resistant, making them suitable for use in wet and corrosive environments commonly found in mining operations.

Overall, the benefits of using polyurethane screens in mining operations are clear. Their durability, flexibility, screening efficiency, self-cleaning properties, and ease of installation make them a superior choice for companies looking to improve their screening processes. By investing in polyurethane screens, mining companies can increase productivity, reduce maintenance costs, and enhance overall operational efficiency.

In conclusion, polyurethane screens offer numerous advantages that make them an ideal choice for mining operations. Their durability, flexibility, screening efficiency, self-cleaning properties, and ease of installation set them apart from traditional steel screens. By choosing polyurethane screens, mining companies can improve their screening processes, increase productivity, and reduce operating costs. With these benefits in mind, it is clear that polyurethane screens are a valuable investment for any mining operation looking to optimize its screening equipment.

How to Properly Maintain and Extend the Lifespan of Mining Vibrating Screens

Mining vibrating screens are essential equipment in the mining industry, as they are used to separate materials based on their size. These screens are typically made of polyurethane, a durable material that can withstand the harsh conditions of mining operations. Proper maintenance of mining vibrating screens is crucial to ensure their longevity and efficiency. In this article, we will discuss some tips on how to properly maintain and extend the lifespan of mining vibrating screens.

One of the most important aspects of maintaining mining vibrating screens is regular cleaning. Over time, dust, dirt, and other debris can accumulate on the screen surface, which can affect its performance. To clean the screen, use a soft brush or cloth to remove any buildup. Avoid using harsh chemicals or abrasive materials, as they can damage the polyurethane material. Regular cleaning will help prevent clogging and ensure that the screen operates smoothly.

In addition to cleaning, it is also important to inspect the screen regularly for any signs of wear or damage. Check for tears, holes, or other defects that may affect the screen’s performance. If any damage is found, it should be repaired or replaced immediately to prevent further deterioration. Regular inspections will help identify potential issues early on and prevent costly repairs or replacements down the line.

Another important aspect of maintaining mining vibrating screens is proper storage. When not in use, screens should be stored in a dry, cool place to prevent damage from moisture or extreme temperatures. Avoid storing screens in direct sunlight or near heat sources, as this can cause the polyurethane material to degrade. Proper storage will help extend the lifespan of the screen and ensure that it remains in good condition for longer.

In addition to cleaning, inspecting, and storing mining vibrating screens properly, it is also important to use them correctly. Avoid overloading the screen with materials beyond its capacity, as this can cause excessive wear and damage. Follow the manufacturer’s guidelines for operating the screen and make sure to use it within its specified limits. Proper usage will help prevent premature wear and extend the lifespan of the screen.

Regular maintenance is key to ensuring the longevity and efficiency of mining vibrating screens. By following these tips, you can properly maintain your screens and extend their lifespan. Remember to clean the screen regularly, inspect it for damage, store it properly, and use it correctly to prevent premature wear and ensure optimal performance. With proper maintenance, your mining vibrating screens will continue to operate efficiently and effectively for years to come.