洗煤尾礦脫水用高頻脫水聚氨酯篩板

高頻脫水聚氨酯篩板在洗煤中的優點 高頻聚氨酯篩板尾礦脫水的創新 用於洗煤和尾礦脫水的高頻脫水聚氨酯篩板 在選礦領域,高效、可持續地管理尾礦是一項嚴峻的挑戰。高頻脫水聚氨酯篩板的推出標誌著該領域的重大進步,特別是在洗煤和尾礦脫水過程中。這些創新的篩板經過精心設計,旨在增強採礦材料中水的分離和去除,從而促進更好的廢物管理並減少對環境的影響。性和撕裂性而聞名,是一種理想的材料。與金屬或橡膠等傳統材料相比,在篩板中使用聚氨酯可顯著延長其使用壽命。此外,聚氨酯的靈活性允許設計能夠有效處理不同進料和條件的篩網,這在礦物加工的動態環境中至關重要。透過增加振動頻率,這些篩子可以更快、更有效率地處理材料,從而實現更精細的分離。這對於洗煤和尾礦脫水尤其重要,其中超細顆粒的去除至關重要。高頻振動導致顆粒分層,這意味著較小的顆粒更接近篩網表面並被更快地去除,從而改善脫水並降低最終廢物中的水分含量。非致盲機制。傳統的篩分解決方案可能會出現篩網堵塞問題,即顆粒堵塞篩孔,嚴重降低效率。聚氨酯篩板採用特定的錐度和槽配置設計,有助於防止此問題,保持高運作效率並減少清潔和維護的停機時間。了尾礦所含的水量。由於多種原因,這種減少至關重要。首先,它最大限度地減少了尾礦壩的尺寸和結構要求,尾礦壩用於儲存採礦過程中的廢棄物。較小的水壩可以降低災難性故障的風險,災難性故障在歷史上曾導致嚴重的環境破壞和傷亡。其次,尾礦中的水較少意味著當地水道污染的可能性較小,這是保護周圍生態系統的關鍵因素。透過將回收的水再循環回採礦過程中,公司可以減少淡水的攝取量,這在缺水地區尤其重要。這不僅有助於保護天然水資源,而且也符合全球為實現更永續和環保的採礦作業而做出的努力。它們能夠有效分離細顆粒並降低尾礦中的水含量,從而提高營運效率和環境永續性。隨著採礦業繼續面臨對其環境影響的嚴格審查,採用此類創新技術對於在保持經濟活力的同時實現全球永續發展目標至關重要。 In conclusion, high frequency Dewatering polyurethane screen panels offer a multitude of benefits for coal washing applications. Their…

高頻脫水聚氨酯篩板在洗煤中的優點

高頻聚氨酯篩板尾礦脫水的創新

用於洗煤和尾礦脫水的高頻脫水聚氨酯篩板

在選礦領域,高效、可持續地管理尾礦是一項嚴峻的挑戰。高頻脫水聚氨酯篩板的推出標誌著該領域的重大進步,特別是在洗煤和尾礦脫水過程中。這些創新的篩板經過精心設計,旨在增強採礦材料中水的分離和去除,從而促進更好的廢物管理並減少對環境的影響。性和撕裂性而聞名,是一種理想的材料。與金屬或橡膠等傳統材料相比,在篩板中使用聚氨酯可顯著延長其使用壽命。此外,聚氨酯的靈活性允許設計能夠有效處理不同進料和條件的篩網,這在礦物加工的動態環境中至關重要。透過增加振動頻率,這些篩子可以更快、更有效率地處理材料,從而實現更精細的分離。這對於洗煤和尾礦脫水尤其重要,其中超細顆粒的去除至關重要。高頻振動導致顆粒分層,這意味著較小的顆粒更接近篩網表面並被更快地去除,從而改善脫水並降低最終廢物中的水分含量。非致盲機制。傳統的篩分解決方案可能會出現篩網堵塞問題,即顆粒堵塞篩孔,嚴重降低效率。聚氨酯篩板採用特定的錐度和槽配置設計,有助於防止此問題,保持高運作效率並減少清潔和維護的停機時間。了尾礦所含的水量。由於多種原因,這種減少至關重要。首先,它最大限度地減少了尾礦壩的尺寸和結構要求,尾礦壩用於儲存採礦過程中的廢棄物。較小的水壩可以降低災難性故障的風險,災難性故障在歷史上曾導致嚴重的環境破壞和傷亡。其次,尾礦中的水較少意味著當地水道污染的可能性較小,這是保護周圍生態系統的關鍵因素。透過將回收的水再循環回採礦過程中,公司可以減少淡水的攝取量,這在缺水地區尤其重要。這不僅有助於保護天然水資源,而且也符合全球為實現更永續和環保的採礦作業而做出的努力。它們能夠有效分離細顆粒並降低尾礦中的水含量,從而提高營運效率和環境永續性。隨著採礦業繼續面臨對其環境影響的嚴格審查,採用此類創新技術對於在保持經濟活力的同時實現全球永續發展目標至關重要。

Innovations In Tailing Dewatering With High Frequency Polyurethane Screen Panels

High Frequency Dewatering polyurethane screen panel for Coal Washing and Tailing Dewatering

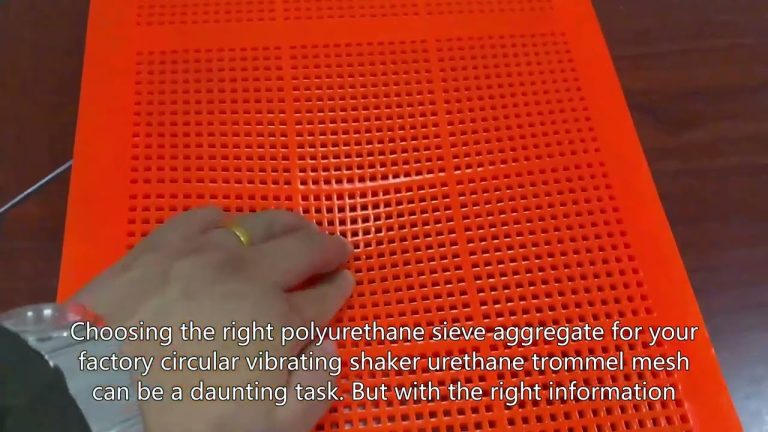

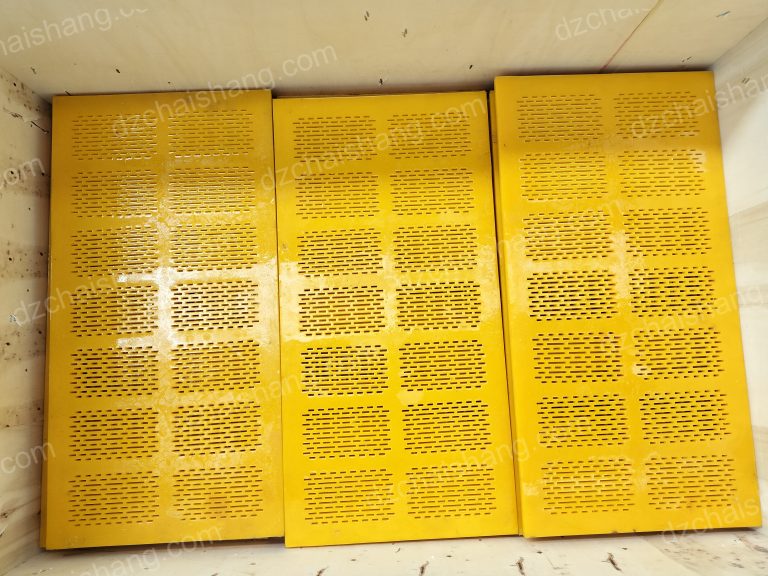

In the realm of mineral processing, managing tailings efficiently and sustainably is a critical challenge. The introduction of high frequency dewatering polyurethane screen panels marks a significant advancement in the field, particularly in the processes of coal washing and tailings dewatering. These innovative screen panels are engineered to enhance the separation and removal of water from mined materials, thereby facilitating better waste management and reducing environmental impact.

Polyurethane, known for its exceptional durability and resistance to abrasion, wear, and tear, is an ideal material for the harsh environments of mining operations. The use of polyurethane in screen panels significantly extends their lifespan compared to traditional materials like metal or rubber. Moreover, the flexibility of polyurethane allows for the design of screens that can effectively handle varying feed materials and conditions, which is crucial in the dynamic environment of mineral processing.

The high frequency aspect of these screen panels is particularly beneficial in fine particle separation. By increasing the frequency of vibrations, these screens can process materials more quickly and efficiently, resulting in finer separations. This is especially important in coal washing and tailings dewatering where the removal of ultra-fine particles is essential. The high frequency vibrations cause the particles to stratify, which means the smaller particles come closer to the screen surface and are removed faster, leading to improved dewatering and reduced moisture content in the final waste product.

Furthermore, the design of these screen panels often includes a non-blinding mechanism. Traditional screening solutions can suffer from screen blinding — where particles clog the screen openings — which severely reduces efficiency. Polyurethane screen panels are designed with specific tapering and slot configurations that help prevent this issue, maintaining high operational efficiency and reducing downtime for cleaning and maintenance.

Transitioning to the environmental benefits, the improved dewatering capability of high frequency polyurethane screen panels significantly reduces the volume of water contained in tailings. This reduction is crucial for several reasons. Firstly, it minimizes the size and structural requirements of tailings dams, which are used to store the waste materials from mining processes. Smaller dams reduce the risk of catastrophic failures, which have historically led to severe environmental damage and loss of life. Secondly, less water in the tailings means less potential for contamination of local waterways, a critical factor in preserving the surrounding ecosystems.

Moreover, the reduction in water usage is a step towards more sustainable mining practices. By recirculating the recovered water back into the mining process, companies can decrease their freshwater intake, which is particularly important in water-scarce regions. This not only helps in conserving natural water resources but also aligns with global efforts towards achieving more sustainable and environmentally friendly mining operations.

In conclusion, high frequency dewatering polyurethane screen panels represent a transformative development in the mining industry. Their ability to efficiently separate fine particles and reduce water content in tailings enhances both operational efficiency and environmental sustainability. As the mining sector continues to face intense scrutiny over its environmental impact, adopting such innovative technologies will be crucial in aligning with global sustainability goals while maintaining economic viability.