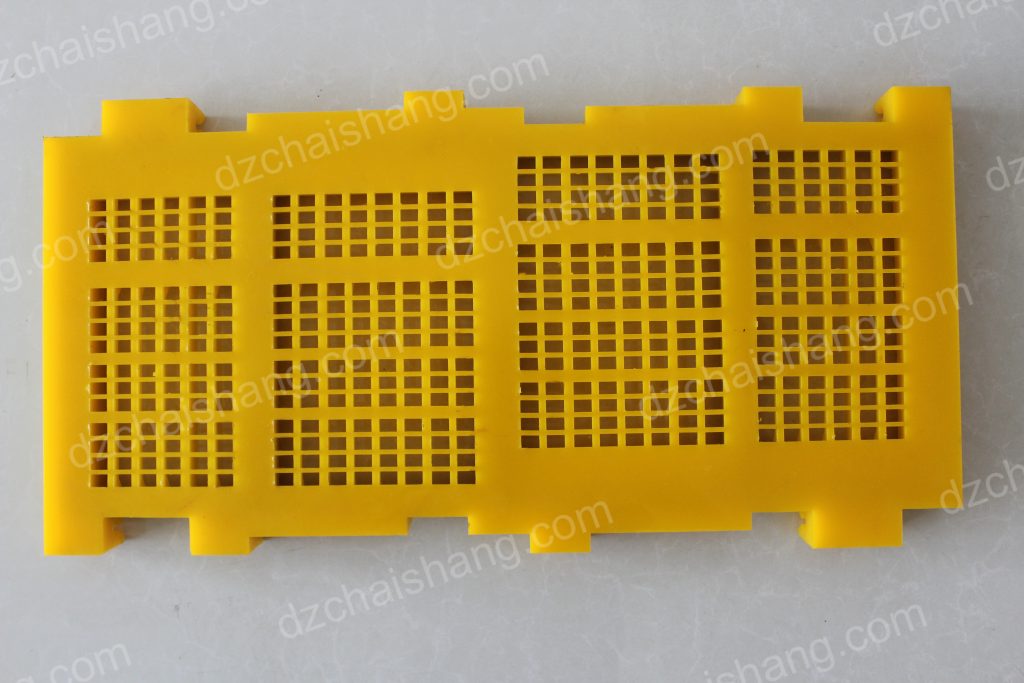

優質振動篩圓形振動聚氨酯板

使用優質振動篩圓形振動聚氨酯板的好處 如何選擇優質的振動篩圓形振動聚氨酯板 在選擇最優質的振動篩圓形振動聚氨酯板時,有幾個因素需要考慮。聚氨酯板通常用於振動篩,根據尺寸分離材料。它們以其耐用性、靈活性和耐磨性而聞名,使其成為採礦、建築和回收等各個行業的理想選擇。高品質聚氨酯板採用優質聚氨酯材料製成,耐磨損。這確保了板在重載條件下使用壽命更長且性能更好。尋找由原始聚氨酯材料製成的板材非常重要,因為回收材料可能無法提供相同等級的耐用性和性能。板上孔徑的形狀和尺寸將決定篩選過程的效率。為所加工的材料選擇孔徑尺寸合適的板子非常重要。孔徑較小的板子非常適合精細材料,而孔徑較大的板子更適合較大的材料。此外,板材的設計應考慮到易於安裝和維護,因為這將有助於延長板材的使用壽命。用鋼或其他材料加固的板更耐用且不易損壞。選擇足夠堅固的板來承受其應用的嚴酷條件非常重要。此外,具有光滑表面光潔度的板材不太可能滯留材料,並且更容易清潔,這有助於提高整體效率。具有生產高品質產品歷史的信譽良好的製造商更有可能提供符合行業標準和規範的印版。對不同製造商進行研究並閱讀其他客戶的評論非常重要,以確保您選擇可靠且信譽良好的供應商。 、設計、構造和製造商。透過花時間研究和比較不同的選擇,您可以確保您投資的印版能夠提供持久的性能和效率。請記住考慮您應用的特定要求,並選擇專為滿足這些需求而量身定制的板子。使用正確的聚氨酯板,您可以提高篩選過程的效率和生產力。 Furthermore, polyurethane plates are easy to install and replace, making maintenance and repairs quick and hassle-free. This means…

使用優質振動篩圓形振動聚氨酯板的好處

如何選擇優質的振動篩圓形振動聚氨酯板

在選擇最優質的振動篩圓形振動聚氨酯板時,有幾個因素需要考慮。聚氨酯板通常用於振動篩,根據尺寸分離材料。它們以其耐用性、靈活性和耐磨性而聞名,使其成為採礦、建築和回收等各個行業的理想選擇。高品質聚氨酯板採用優質聚氨酯材料製成,耐磨損。這確保了板在重載條件下使用壽命更長且性能更好。尋找由原始聚氨酯材料製成的板材非常重要,因為回收材料可能無法提供相同等級的耐用性和性能。板上孔徑的形狀和尺寸將決定篩選過程的效率。為所加工的材料選擇孔徑尺寸合適的板子非常重要。孔徑較小的板子非常適合精細材料,而孔徑較大的板子更適合較大的材料。此外,板材的設計應考慮到易於安裝和維護,因為這將有助於延長板材的使用壽命。用鋼或其他材料加固的板更耐用且不易損壞。選擇足夠堅固的板來承受其應用的嚴酷條件非常重要。此外,具有光滑表面光潔度的板材不太可能滯留材料,並且更容易清潔,這有助於提高整體效率。具有生產高品質產品歷史的信譽良好的製造商更有可能提供符合行業標準和規範的印版。對不同製造商進行研究並閱讀其他客戶的評論非常重要,以確保您選擇可靠且信譽良好的供應商。 、設計、構造和製造商。透過花時間研究和比較不同的選擇,您可以確保您投資的印版能夠提供持久的性能和效率。請記住考慮您應用的特定要求,並選擇專為滿足這些需求而量身定制的板子。使用正確的聚氨酯板,您可以提高篩選過程的效率和生產力。

Furthermore, polyurethane plates are easy to install and replace, making maintenance and repairs quick and hassle-free. This means less downtime for the screening equipment, allowing for continuous operation and increased productivity. The ease of installation also means that operators can quickly switch out worn or damaged plates, ensuring that the screen remains in optimal condition at all times.

In terms of performance, a good quality shaker circular vibrating polyurethane plate offers superior screening efficiency and accuracy. The smooth surface of the polyurethane material allows for efficient material flow and separation, resulting in a higher quality end product. This is essential for industries such as mining, construction, and recycling, where the accuracy of screening results can have a significant impact on overall production and profitability.

Overall, the benefits of using a good quality shaker circular vibrating polyurethane plate are clear. From its durability and flexibility to its resistance to abrasion and noise reduction capabilities, polyurethane plates offer a range of advantages that can improve the efficiency and effectiveness of the screening process. With easy installation and maintenance, as well as superior screening performance, polyurethane plates are a reliable and cost-effective solution for industries that rely on efficient material processing.

How to Choose the Best Good Quality Shaker Circular Vibrating Polyurethane Plate

When it comes to choosing the best quality shaker circular vibrating polyurethane plate, there are several factors to consider. Polyurethane plates are commonly used in vibrating screens to separate materials based on size. They are known for their durability, flexibility, and resistance to abrasion, making them an ideal choice for various industries such as mining, construction, and recycling.

One of the most important factors to consider when choosing a polyurethane plate is the material quality. High-quality polyurethane plates are made from premium-grade polyurethane material that is resistant to wear and tear. This ensures that the plate will last longer and perform better under heavy-duty conditions. It is important to look for plates that are made from virgin polyurethane material, as recycled material may not offer the same level of durability and performance.

Another important factor to consider is the design of the polyurethane plate. The shape and size of the apertures on the plate will determine the efficiency of the screening process. It is important to choose a plate with the right aperture size for the material being processed. Plates with smaller apertures are ideal for fine materials, while plates with larger apertures are better suited for larger materials. Additionally, the design of the plate should allow for easy installation and maintenance, as this will help to prolong the life of the plate.

In addition to material quality and design, it is also important to consider the overall construction of the polyurethane plate. Plates that are reinforced with steel or other materials are more durable and resistant to damage. It is important to choose a plate that is strong enough to withstand the rigors of the application it will be used for. Additionally, plates with a smooth surface finish are less likely to trap material and are easier to clean, which can help to improve overall efficiency.

When choosing a polyurethane plate, it is also important to consider the manufacturer. Reputable manufacturers with a history of producing high-quality products are more likely to provide plates that meet industry standards and specifications. It is important to do research on different manufacturers and read reviews from other customers to ensure that you are choosing a reliable and reputable supplier.

Overall, choosing the best quality shaker circular vibrating polyurethane plate requires careful consideration of material quality, design, construction, and manufacturer. By taking the time to research and compare different options, you can ensure that you are investing in a plate that will provide long-lasting performance and efficiency. Remember to consider the specific requirements of your application and choose a plate that is tailored to meet those needs. With the right polyurethane plate, you can improve the efficiency and productivity of your screening process.