脫水篩網、張力篩網、PU塗層絲篩網

探索脫水篩網在工業應用上的效率 張緊篩網介質在增強篩網性能方面的作用 總而言之,所使用的篩選介質類型可以顯著影響篩選過程的效能。脫水篩網、張力篩網介質和 PU 塗層金屬絲篩網介質均具有獨特的功能和優點,可以以不同的方式增強篩分性能。透過了解這些差異並為給定應用選擇最合適的篩選介質類型,業界可以優化其篩選過程並獲得更好的結果。無論是透過脫水篩網提高效率、透過張緊篩網提高精度,或是透過 PU 塗層金屬絲篩網延長使用壽命,正確選擇篩網都會產生顯著的影響。 The role of tensioned screen media in enhancing screening performance is a topic of significant…

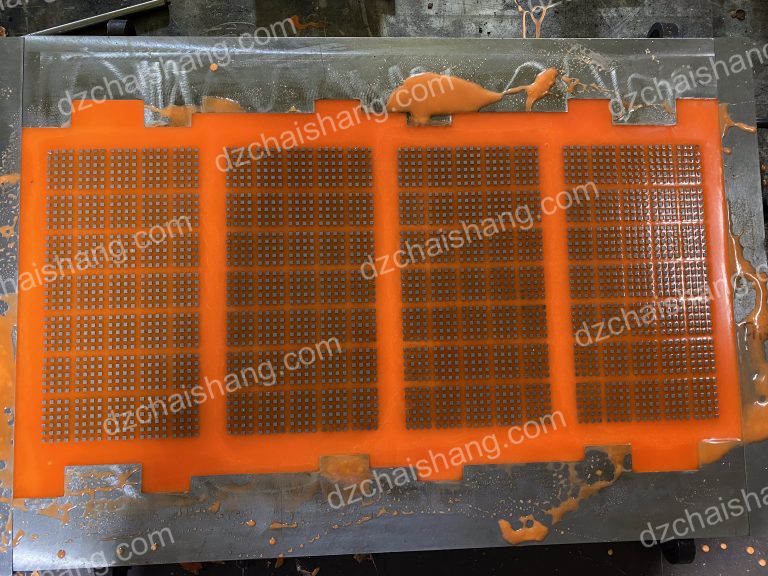

探索脫水篩網在工業應用上的效率

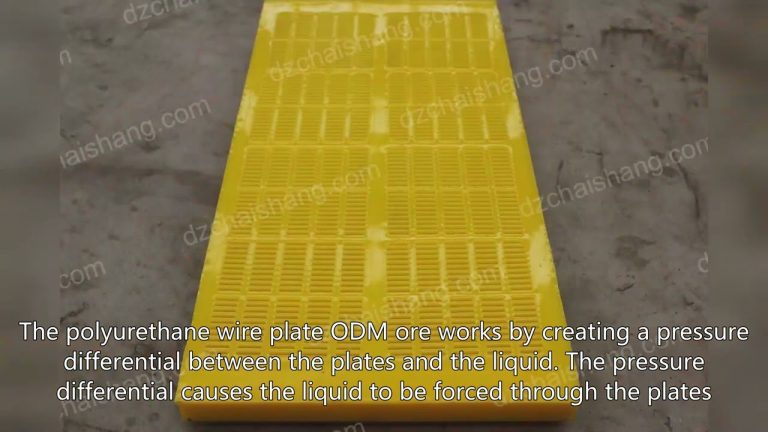

張緊篩網介質在增強篩網性能方面的作用

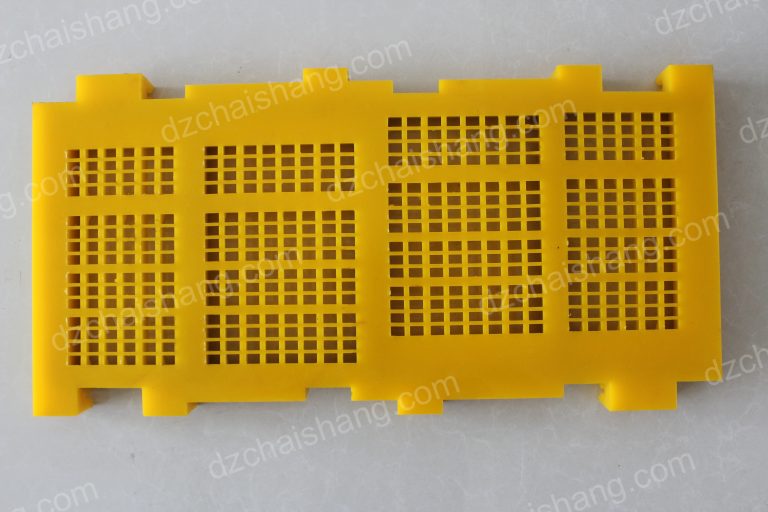

總而言之,所使用的篩選介質類型可以顯著影響篩選過程的效能。脫水篩網、張力篩網介質和 PU 塗層金屬絲篩網介質均具有獨特的功能和優點,可以以不同的方式增強篩分性能。透過了解這些差異並為給定應用選擇最合適的篩選介質類型,業界可以優化其篩選過程並獲得更好的結果。無論是透過脫水篩網提高效率、透過張緊篩網提高精度,或是透過 PU 塗層金屬絲篩網延長使用壽命,正確選擇篩網都會產生顯著的影響。

The role of tensioned screen media in enhancing screening performance is a topic of significant importance in industries such as mining, quarrying, and waste management. These industries rely heavily on screening processes to separate materials of different sizes or characteristics. The efficiency and effectiveness of these processes are largely determined by the type of screen media used. Among the various types of screen media available, dewatering screen mesh, tensioned screen media, and PU coated wire screen media are particularly noteworthy for their unique features and benefits.

Dewatering screen mesh is a type of screen media that is specifically designed to remove water from wet materials. This is achieved through a combination of high-frequency vibrations and a unique screen design that allows water to pass through while retaining the solid particles. The use of dewatering screen mesh can significantly enhance the efficiency of screening processes, particularly in industries where materials are often wet or damp. By removing excess water, dewatering screen mesh not only improves the quality of the screened materials but also reduces the load on downstream equipment, thereby enhancing overall operational efficiency.

Tensioned screen media, on the other hand, is characterized by its tight fit on the screening machine. This is achieved through the use of tensioning hooks or bolts that secure the screen media to the machine. The tensioned fit ensures that the screen media remains flat and taut during operation, thereby preventing any sagging or waving that could compromise the screening performance. Moreover, tensioned screen media is typically made of high-strength materials that resist wear and tear, thereby ensuring long-lasting performance. The use of tensioned screen media can significantly enhance the accuracy and consistency of screening processes, particularly in industries where precision is paramount.

PU coated wire screen media is another type of screen media that offers unique benefits. The PU coating, which stands for polyurethane, provides a protective layer that enhances the durability and longevity of the wire screen. This is particularly beneficial in industries where the screened materials are abrasive or corrosive, as the PU coating can resist such damaging effects. Moreover, the PU coating also provides a smooth surface that reduces friction and prevents material from sticking to the screen, thereby enhancing the flow and efficiency of the screening process. The use of PU coated wire screen media can significantly enhance the performance and lifespan of screening machines, thereby providing a cost-effective solution for industries that rely heavily on screening processes.

In conclusion, the type of screen media used can significantly influence the performance of screening processes. Dewatering screen mesh, tensioned screen media, and PU coated wire screen media each offer unique features and benefits that can enhance screening performance in different ways. By understanding these differences and selecting the most suitable type of screen media for a given application, industries can optimize their screening processes and achieve better results. Whether it’s improving efficiency with dewatering screen mesh, enhancing accuracy with tensioned screen media, or extending lifespan with PU coated wire screen media, the right choice of screen media can make a significant difference.