脫水篩設計,振動篩網報價

脫水篩設計:最佳性能的關鍵考量 除了尺寸、形狀和傾斜角度之外,振動篩網的設計對於最佳脫水性能也至關重要。應根據所加工材料的尺寸和類型以及所需的脫水等級來選擇篩網。較細的網格將去除更多的水分,但也可能會降低產量,而較粗的網格將允許更高的產量,但可能無法達到所需的脫水水平。選擇正確的篩孔尺寸和類型對於獲得最佳效果至關重要。篩網的振動有助於使材料在篩網表面移動並促進脫水過程。應仔細調整振動的頻率和振幅,以達到最佳的物料運動和脫水效率。必須在振動頻率和振幅之間找到適當的平衡,以最大限度地提高性能。孔,以及振動頻率和振幅。考慮這些因素並在它們之間找到適當的平衡,可以設計出具有最佳性能和效率的脫水篩。透過正確的設計,脫水篩可以有效去除材料中的多餘水分,並提高採礦和骨材作業的整體加工效率。 One of the most important factors to consider when designing a dewatering screen is the size and shape of the…

脫水篩設計:最佳性能的關鍵考量

除了尺寸、形狀和傾斜角度之外,振動篩網的設計對於最佳脫水性能也至關重要。應根據所加工材料的尺寸和類型以及所需的脫水等級來選擇篩網。較細的網格將去除更多的水分,但也可能會降低產量,而較粗的網格將允許更高的產量,但可能無法達到所需的脫水水平。選擇正確的篩孔尺寸和類型對於獲得最佳效果至關重要。篩網的振動有助於使材料在篩網表面移動並促進脫水過程。應仔細調整振動的頻率和振幅,以達到最佳的物料運動和脫水效率。必須在振動頻率和振幅之間找到適當的平衡,以最大限度地提高性能。孔,以及振動頻率和振幅。考慮這些因素並在它們之間找到適當的平衡,可以設計出具有最佳性能和效率的脫水篩。透過正確的設計,脫水篩可以有效去除材料中的多餘水分,並提高採礦和骨材作業的整體加工效率。

One of the most important factors to consider when designing a dewatering screen is the size and shape of the screen openings. The size of the openings will determine the amount of material that can pass through the screen, while the shape of the openings will affect the efficiency of the dewatering process. It is essential to choose the right combination of size and shape to achieve the desired level of dewatering.

Another critical aspect of dewatering screen design is the angle of inclination. The angle at which the screen is inclined will impact the speed at which the material moves across the screen surface and the efficiency of the dewatering process. A steeper angle will result in faster material movement but may also lead to reduced dewatering efficiency. It is important to find the optimal angle of inclination that balances material flow and dewatering performance.

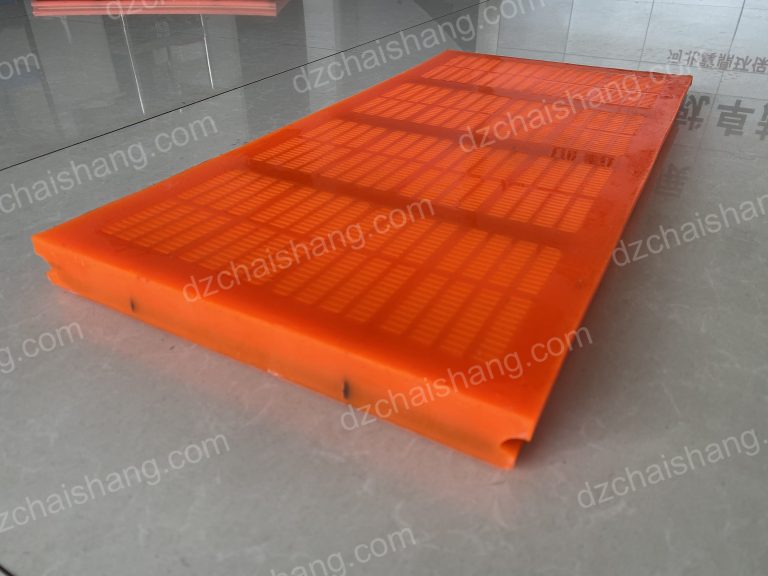

In addition to size, shape, and angle of inclination, the design of the vibrating screen mesh is also crucial for optimal dewatering performance. The mesh should be selected based on the size and type of material being processed, as well as the desired level of dewatering. A finer mesh will remove more moisture but may also reduce throughput, while a coarser mesh will allow for higher throughput but may not achieve the desired level of dewatering. It is essential to choose the right mesh size and type to achieve the best results.

When designing a dewatering screen, it is also important to consider the vibration frequency and amplitude. The vibration of the screen helps to move the material across the screen surface and facilitate the dewatering process. The frequency and amplitude of the vibration should be carefully adjusted to achieve optimal material movement and dewatering efficiency. It is essential to find the right balance between vibration frequency and amplitude to maximize performance.

In conclusion, designing a dewatering screen requires careful consideration of several key factors, including the size and shape of the screen openings, the angle of inclination, the vibrating screen mesh, and the vibration frequency and amplitude. By taking these factors into account and finding the right balance between them, it is possible to design a dewatering screen that delivers optimal performance and efficiency. With the right design, a dewatering screen can effectively remove excess moisture from materials and improve overall processing efficiency in mining and aggregate operations.