廉價張緊聚氨酯篩網,製造商振動張緊聚氨酯板

探索便宜的張緊聚氨酯篩網的優點 了解振動張緊聚氨酯板的製造過程 聚氨酯完全固化後,將螢幕從模具中取出。在此階段,將檢查螢幕是否有任何缺陷或不一致之處。如果發現任何問題,螢幕將被修復或丟棄,這取決於缺陷的嚴重程度。這個品質控制步驟對於確保離開製造工廠的每個螢幕都具有最高品質至關重要。這些掛鉤固定在螢幕邊緣,用於在操作過程中將螢幕固定到位。張力鉤的設計能夠承受高強度的張力,確保螢幕即使在重載下也能保持拉緊和有效。的特性。然而,其結果是產品耐用、高效且具有成本效益。這些篩網是許多行業的必備工具,即使在最苛刻的條件下也能提供可靠的性能。鉤子。每個步驟對於確保最終產品具有最高品質並能夠承受高水平的張力和振動至關重要。透過了解這個過程,人們可以體會到這些螢幕的價值和可靠性,使它們成為任何需要重型篩選解決方案的行業的一項值得投資。 Understanding the manufacturing process of vibrating tensioned urethane plates is crucial for those in industries such as mining, construction,…

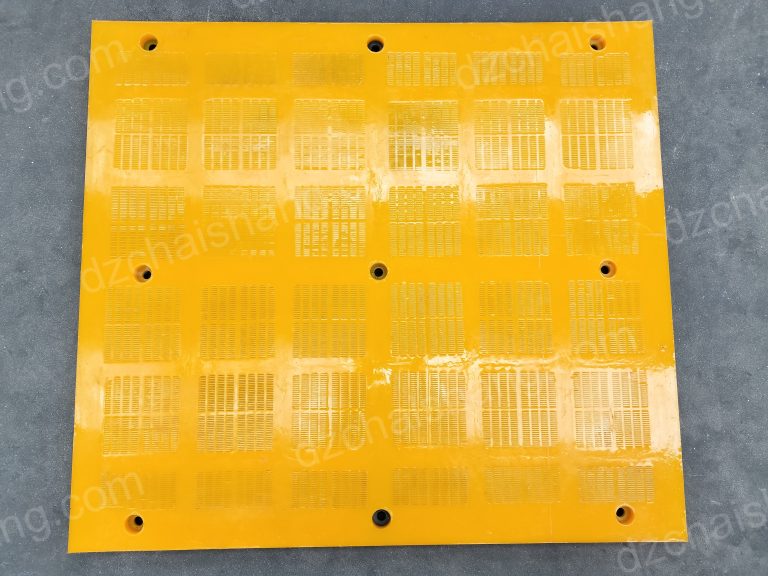

探索便宜的張緊聚氨酯篩網的優點

了解振動張緊聚氨酯板的製造過程

聚氨酯完全固化後,將螢幕從模具中取出。在此階段,將檢查螢幕是否有任何缺陷或不一致之處。如果發現任何問題,螢幕將被修復或丟棄,這取決於缺陷的嚴重程度。這個品質控制步驟對於確保離開製造工廠的每個螢幕都具有最高品質至關重要。這些掛鉤固定在螢幕邊緣,用於在操作過程中將螢幕固定到位。張力鉤的設計能夠承受高強度的張力,確保螢幕即使在重載下也能保持拉緊和有效。的特性。然而,其結果是產品耐用、高效且具有成本效益。這些篩網是許多行業的必備工具,即使在最苛刻的條件下也能提供可靠的性能。鉤子。每個步驟對於確保最終產品具有最高品質並能夠承受高水平的張力和振動至關重要。透過了解這個過程,人們可以體會到這些螢幕的價值和可靠性,使它們成為任何需要重型篩選解決方案的行業的一項值得投資。

Understanding the manufacturing process of vibrating tensioned urethane plates is crucial for those in industries such as mining, construction, and aggregate production. These plates, also known as tensioned urethane screens, are renowned for their durability, efficiency, and cost-effectiveness. They are designed to withstand high levels of tension and vibration, making them ideal for heavy-duty applications.

The manufacturing process of these screens begins with the selection of high-quality urethane. Urethane, a type of polymer, is chosen for its exceptional resistance to wear, tear, and environmental conditions. It is also highly flexible, allowing it to absorb impact and resist deformation. This makes it an excellent material for screens that need to endure constant vibration and tension.

Once the urethane is selected, it is heated until it reaches a liquid state. This liquid urethane is then poured into a mold that has been designed to the exact specifications of the finished screen. The mold is typically made from aluminum or steel and is crafted with precision to ensure the final product meets the required dimensions and performance standards.

After the liquid urethane is poured into the mold, it is left to cool and harden. This process, known as curing, can take several hours to complete. During this time, the urethane transforms from a liquid into a solid, taking on the shape of the mold. The curing process is carefully monitored to ensure the urethane hardens evenly and maintains its shape.

Once the urethane has fully cured, the screen is removed from the mold. At this stage, the screen is inspected for any defects or inconsistencies. If any are found, the screen is either repaired or discarded, depending on the severity of the defect. This quality control step is crucial in ensuring that every screen that leaves the manufacturing facility is of the highest quality.

The final step in the manufacturing process is the addition of tension hooks. These hooks are attached to the edges of the screen and are used to secure the screen in place during operation. The tension hooks are designed to withstand high levels of tension, ensuring the screen remains taut and effective even under heavy loads.

The manufacturing process of vibrating tensioned urethane plates is a complex one, requiring precision, quality control, and a deep understanding of the properties of urethane. However, the result is a product that is durable, efficient, and cost-effective. These screens are an essential tool in many industries, providing reliable performance even in the most demanding conditions.

In conclusion, the manufacturing process of vibrating tensioned urethane plates involves several steps, from the selection of high-quality urethane to the addition of tension hooks. Each step is crucial in ensuring the final product is of the highest quality and capable of withstanding high levels of tension and vibration. By understanding this process, one can appreciate the value and reliability of these screens, making them a worthwhile investment for any industry that requires heavy-duty screening solutions.