聚氨酯篩網的基本介紹

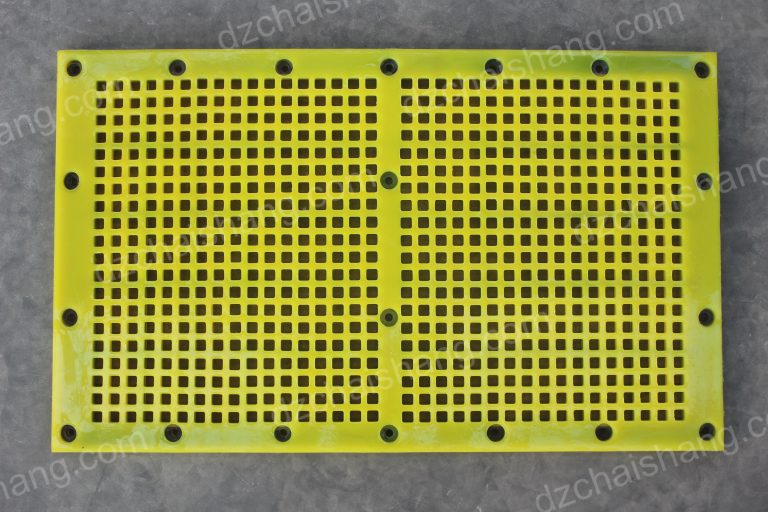

聚氨酯篩網概述 聚氨酯篩網的主要優點之一是其耐用性。與傳統的金屬絲網篩不同,聚氨酯篩網不易破裂或磨損。它們可以承受高衝擊力並且耐腐蝕,適合在惡劣環境中使用。此外,與其他類型的篩網相比,聚氨酯篩網的使用壽命更長,從長遠來看,減少了頻繁更換的需要並節省了成本。性。這些螢幕可以製造成不同程度的硬度,從而可以根據特定的應用要求進行客製化。軟質聚氨酯篩網更適合篩分水分含量高的物料,因為它們可以防止堵塞和堵塞。另一方面,較硬的聚氨酯篩網用於涉及重型篩分的應用,例如採礦和骨材加工。這些篩網的光滑表面減少了摩擦,使物料更自由地流動並防止堵塞。這會帶來更高的吞吐量和更高的生產力。此外,聚氨酯篩網的靈活性使其能夠符合被篩分材料的形狀,確保精確的分離和分類。在採礦業中,這些篩網用於對礦物進行分離和分類,確保高效加工並最大限度地提高產量。在骨材產業中,聚氨酯篩網用於篩分碎石、砂和礫石,從而生產出高品質的骨材。其他受惠於聚氨酯篩網使用的產業包括回收、建築和化學加工。它們採用液體聚氨酯結構,可實現精確的尺寸和複雜的設計,而其耐用性和靈活性使其適合在惡劣環境中使用。聚氨酯篩網還可以提高篩分效率,從而提高吞吐量和生產率。由於聚氨酯篩網在各行業的廣泛應用,已成為許多篩分操作中的重要組成部分。 One of the key advantages of polyurethane screens is their durability. Unlike traditional wire mesh screens, polyurethane screens are not…

聚氨酯篩網概述

聚氨酯篩網的主要優點之一是其耐用性。與傳統的金屬絲網篩不同,聚氨酯篩網不易破裂或磨損。它們可以承受高衝擊力並且耐腐蝕,適合在惡劣環境中使用。此外,與其他類型的篩網相比,聚氨酯篩網的使用壽命更長,從長遠來看,減少了頻繁更換的需要並節省了成本。性。這些螢幕可以製造成不同程度的硬度,從而可以根據特定的應用要求進行客製化。軟質聚氨酯篩網更適合篩分水分含量高的物料,因為它們可以防止堵塞和堵塞。另一方面,較硬的聚氨酯篩網用於涉及重型篩分的應用,例如採礦和骨材加工。這些篩網的光滑表面減少了摩擦,使物料更自由地流動並防止堵塞。這會帶來更高的吞吐量和更高的生產力。此外,聚氨酯篩網的靈活性使其能夠符合被篩分材料的形狀,確保精確的分離和分類。在採礦業中,這些篩網用於對礦物進行分離和分類,確保高效加工並最大限度地提高產量。在骨材產業中,聚氨酯篩網用於篩分碎石、砂和礫石,從而生產出高品質的骨材。其他受惠於聚氨酯篩網使用的產業包括回收、建築和化學加工。它們採用液體聚氨酯結構,可實現精確的尺寸和複雜的設計,而其耐用性和靈活性使其適合在惡劣環境中使用。聚氨酯篩網還可以提高篩分效率,從而提高吞吐量和生產率。由於聚氨酯篩網在各行業的廣泛應用,已成為許多篩分操作中的重要組成部分。

One of the key advantages of polyurethane screens is their durability. Unlike traditional wire mesh screens, polyurethane screens are not prone to breakage or wear. They can withstand high impact forces and are resistant to corrosion, making them suitable for use in harsh environments. Additionally, polyurethane screens have a longer lifespan compared to other types of screening media, reducing the need for frequent replacements and saving costs in the long run.

Another notable advantage of polyurethane screens is their flexibility. These screens can be manufactured with varying degrees of hardness, allowing for customization based on specific application requirements. Soft polyurethane screens are more suitable for screening materials with high moisture content, as they prevent blinding and clogging. On the other hand, harder polyurethane screens are used for applications that involve heavy-duty screening, such as mining and aggregate processing.

Polyurethane screens also offer improved screening efficiency. The smooth surface of these screens reduces friction, allowing materials to flow more freely and preventing blockages. This results in higher throughput and increased productivity. Additionally, the flexibility of polyurethane screens enables them to conform to the shape of the material being screened, ensuring accurate separation and classification.

The applications of polyurethane screens are diverse and span across various industries. In the mining industry, these screens are used for separating and classifying minerals, ensuring efficient processing and maximizing yield. In the aggregate industry, polyurethane screens are employed in the screening of crushed stone, sand, and gravel, enabling the production of high-quality aggregates. Other industries that benefit from the use of polyurethane screens include recycling, construction, and chemical processing.

In conclusion, polyurethane screens are a versatile and durable screening media that offer numerous advantages over traditional wire mesh screens. Their construction using liquid polyurethane allows for precise dimensions and intricate designs, while their durability and flexibility make them suitable for use in harsh environments. Polyurethane screens also provide improved screening efficiency, resulting in higher throughput and increased productivity. With their wide range of applications across various industries, polyurethane screens have become an essential component in many screening operations.