振動篩板、篩網、脫水篩

探索振動篩板的功能與應用 了解篩網和脫水篩在物料分離中的作用 另一方面,脫水篩又稱為脫水篩,用於除去濕物料中的水分。它是材料在進一步加工前需要乾燥的行業中的重要工具。脫水篩的工作原理是對濕物料施加高頻振動。這種振動迫使水從材料中分離並通過篩子,留下乾燥的材料。與篩網一樣,它可以定制以滿足特定的工業需求。物料的尺寸和性質、要去除的水量以及物料所需的乾燥程度等因素都會影響脫水篩的設計。篩網首先根據尺寸分離材料,然後脫水篩去除多餘的水。這兩個步驟的過程確保分離後的材料不僅具有合適的尺寸,而且充分乾燥以便進一步加工。它們提供了一種根據尺寸和水分含量分離材料的可靠且有效的方法。透過了解它們的作用和功能,產業可以優化其材料分離過程,從而提高效率和生產力。因此,行業專業人士必須認識到這些工具的重要性,並在選擇篩網或脫水篩時考慮其具體要求。 Understanding the Role of screen mesh and Dewatering Sieve in Material Separation In the realm of material separation, two…

探索振動篩板的功能與應用

了解篩網和脫水篩在物料分離中的作用

Understanding the Role of screen mesh and Dewatering Sieve in Material Separation

In the realm of material separation, two key components play a pivotal role: the screen mesh and the dewatering sieve. These elements, often overlooked, are integral to the process of separating materials of different sizes and densities. They are particularly crucial in industries such as mining, construction, and waste management, where the separation of materials is a routine task.

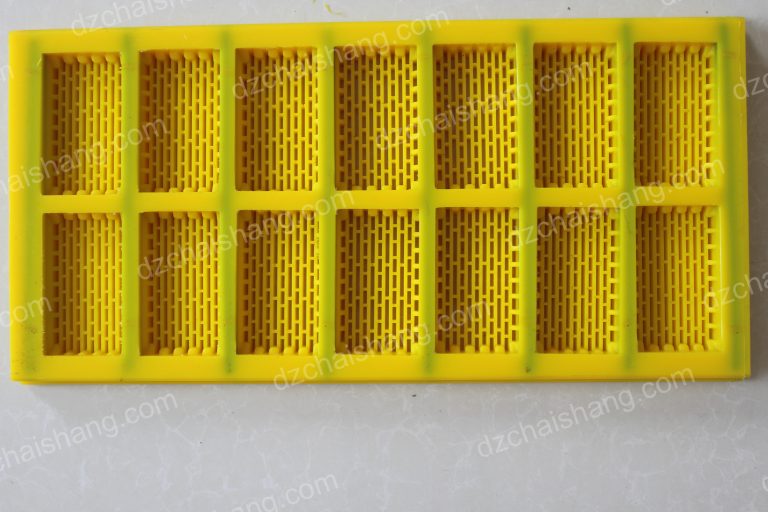

The screen mesh, also known as a vibrator sieve plate, is a metal grid with uniformly sized openings. It is designed to filter materials by size, allowing smaller particles to pass through while retaining larger ones. The size of the openings in the screen mesh can be adjusted according to the specific requirements of the separation process. The screen mesh is typically made of robust materials such as stainless steel or polyurethane to withstand the rigors of industrial use.

The screen mesh’s effectiveness is not solely dependent on the size of its openings. The shape of the openings also plays a significant role. For instance, square openings are ideal for separating materials of similar sizes, while slotted openings are better suited for separating elongated particles. The choice of opening shape is, therefore, dependent on the nature of the materials being separated.

On the other hand, the dewatering sieve, also known as a dewatering screen, is used to remove water from wet materials. It is an essential tool in industries where materials need to be dried before further processing. The dewatering sieve works by applying a high-frequency vibration to the wet material. This vibration forces the water to separate from the material and pass through the sieve, leaving behind the dried material.

The dewatering sieve is not a one-size-fits-all solution. Like the screen mesh, it can be customized to suit specific industrial needs. Factors such as the size and nature of the material, the amount of water to be removed, and the desired dryness level of the material all influence the design of the dewatering sieve.

The combination of the screen mesh and the dewatering sieve provides a comprehensive solution for material separation. The screen mesh first separates the material based on size, after which the dewatering sieve removes any excess water. This two-step process ensures that the separated material is not only of the right size but also sufficiently dry for further processing.

In conclusion, the screen mesh and the dewatering sieve are indispensable tools in the material separation process. They offer a reliable and efficient means of separating materials based on size and moisture content. By understanding their role and functionality, industries can optimize their material separation processes, leading to improved efficiency and productivity. Therefore, it is essential for industry professionals to appreciate the importance of these tools and consider their specific requirements when selecting a screen mesh or a dewatering sieve.