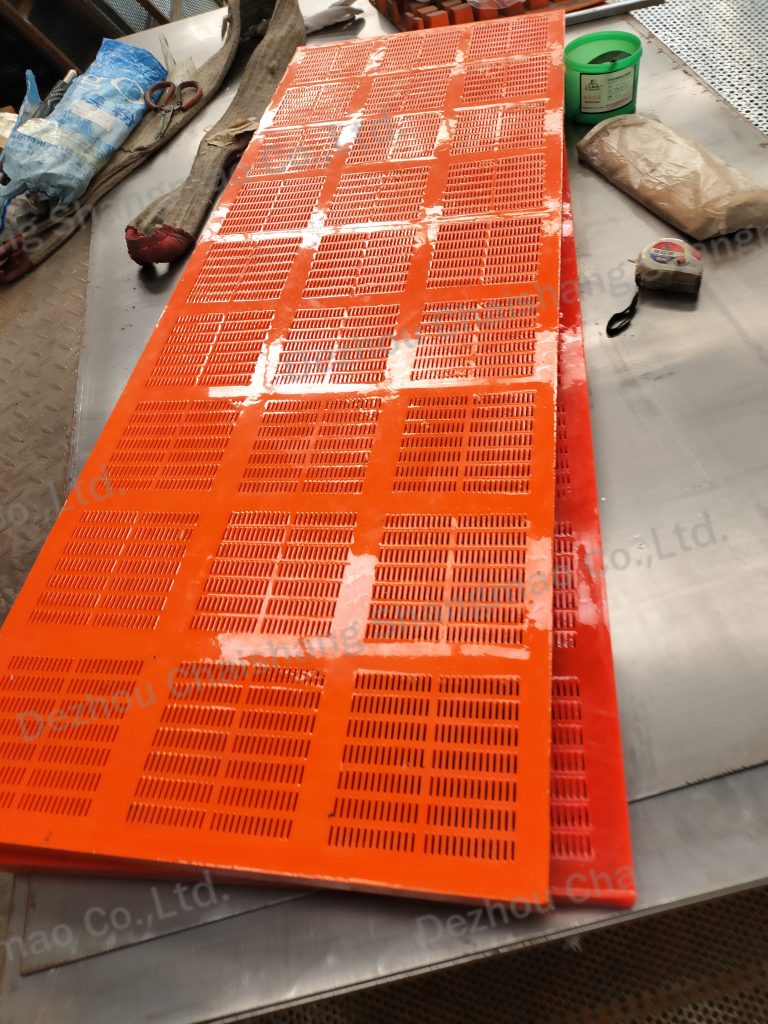

vibrating Urethane mesh,polyurethane screen panel

Benefits of Using Vibrating urethane mesh in Screening Applications Vibrating urethane mesh, also known as polyurethane screen panels, is a popular choice…

Benefits of Using Vibrating urethane mesh in Screening Applications

Vibrating urethane mesh, also known as polyurethane screen panels, is a popular choice for screening applications in various industries. This innovative material offers a range of benefits that make it a superior option compared to traditional metal screens. In this article, we will explore the advantages of using vibrating urethane mesh in screening applications. One of the key benefits of vibrating urethane mesh is its durability. Polyurethane is a highly resilient material that can withstand the wear and tear of constant vibration and screening. Unlike metal screens, which can corrode and degrade over time, urethane mesh maintains its integrity and performance for an extended period. This durability translates to cost savings for businesses, as they do not have to frequently replace worn-out screens. In addition to its durability, vibrating urethane mesh offers excellent abrasion resistance. This is particularly important in industries where abrasive materials are being processed or screened. The polyurethane material can withstand the abrasive forces without wearing down, ensuring a longer lifespan for the screen panels. This resistance to abrasion also contributes to the overall efficiency of the screening process, as the mesh maintains its integrity and effectiveness in separating materials. Another advantage of vibrating urethane mesh is its flexibility. Polyurethane is a versatile material that can be molded into various shapes and sizes to meet specific screening requirements. This flexibility allows for customization of screen panels to fit different screening machines and applications. Whether it is for dewatering, sizing, scalping, or any other screening process, urethane mesh can be tailored to deliver optimal performance. Furthermore, vibrating urethane mesh offers superior screening efficiency. The design of the mesh panels, with their precise apertures and open area, allows for efficient separation of materials. This results in a higher throughput and better quality of screened products. The flexibility of polyurethane also contributes to the efficiency of the screening process, as the panels can be easily installed and replaced as needed. In addition to its durability, abrasion resistance, flexibility, and efficiency, vibrating urethane mesh is also lightweight. This makes handling and installation of the screen panels easier and more convenient. The lightweight nature of polyurethane mesh also reduces the strain on screening machines, leading to improved performance and longevity. Overall, the benefits of using vibrating urethane mesh in screening applications are clear. Its durability, abrasion resistance, flexibility, efficiency, and lightweight nature make it a superior choice for industries that rely on efficient and reliable screening processes. By investing in polyurethane screen panels, businesses can improve their screening operations, reduce maintenance costs, and enhance overall productivity.How to Properly Maintain and Clean Polyurethane Screen Panels

Polyurethane screen panels are a popular choice for many industries due to their durability and efficiency in separating materials. These panels are commonly used in vibrating screens to separate particles by size, making them essential components in various processes such as mining, aggregate production, and recycling. To ensure the longevity and effectiveness of polyurethane screen panels, proper maintenance and cleaning are crucial. One of the key benefits of polyurethane screen panels is their resistance to abrasion and wear, which allows them to withstand the harsh conditions of screening operations. However, regular maintenance is still necessary to prevent premature wear and tear. Inspecting the panels for any signs of damage, such as tears or holes, is essential to ensure that they continue to function properly. Any damaged panels should be replaced promptly to avoid compromising the efficiency of the screening process. In addition to visual inspections, cleaning polyurethane screen panels is also important to maintain their performance. Over time, particles can become trapped in the mesh, reducing the screening efficiency. To clean the panels, it is recommended to use a mild detergent and water solution. Gently scrubbing the panels with a soft brush can help remove any buildup of material and restore their effectiveness.Another method for cleaning polyurethane screen panels is to use a high-pressure washer. This can be particularly effective in removing stubborn debris that may be stuck in the mesh. However, it is important to use caution when using a high-pressure washer, as excessive force can damage the panels. It is recommended to start with a lower pressure setting and gradually increase as needed.

After cleaning the panels, it is important to allow them to dry completely before reinstalling them in the vibrating screen. Moisture trapped in the mesh can lead to mold and mildew growth, which can affect the performance of the panels. Proper drying ensures that the panels are ready for use and helps prevent any potential issues. In addition to regular maintenance and cleaning, proper storage of polyurethane screen panels is also important to prolong their lifespan. Storing the panels in a dry, cool environment away from direct sunlight can help prevent degradation of the material. It is also recommended to store the panels flat or hanging to avoid any bending or warping that can affect their performance. Overall, proper maintenance and cleaning of polyurethane screen panels are essential to ensure their longevity and efficiency in screening operations. By regularly inspecting, cleaning, and storing the panels correctly, you can maximize their performance and minimize downtime. Investing time and effort in maintaining polyurethane screen panels will ultimately result in cost savings and improved productivity in your operations.