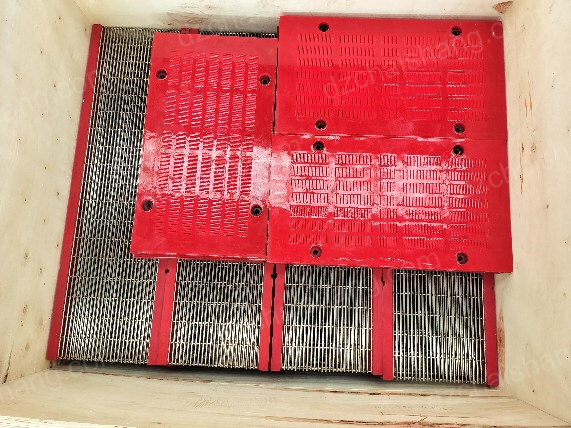

pu screen,pu moulding screen mesh,pu modular screens

Exploring the Benefits of pu screen Technology for Industrial Applications polyurethane (PU) screen technology has emerged as a versatile solution for various…

Exploring the Benefits of pu screen Technology for Industrial Applications

polyurethane (PU) screen technology has emerged as a versatile solution for various industrial applications, offering a range of benefits that contribute to improved efficiency and productivity. From PU screen mesh to pu modular screens, this innovative technology has transformed the landscape of industrial screening processes. In this article, we delve into the key advantages of PU screen technology and its significance in enhancing industrial operations. One of the primary benefits of PU screen technology lies in its durability and resilience. Unlike traditional screening materials, PU screens are highly resistant to abrasion, impact, and wear, ensuring prolonged operational lifespan even in demanding environments. This durability translates to reduced downtime and maintenance costs, making PU screens a cost-effective choice for industrial applications.

Moreover, PU screens offer exceptional flexibility and versatility, allowing for seamless integration into various screening systems. Whether it’s pu moulding screen mesh or PU modular screens, these solutions can be customized to meet specific requirements, including size, shape, and aperture configurations. This adaptability enables precise control over the screening process, enhancing overall efficiency and product quality.

In addition to durability and flexibility, PU screen technology is known for its superior performance characteristics. The inherent properties of polyurethane, such as elasticity and resilience, contribute to efficient particle separation and screening accuracy. As a result, industries ranging from mining and aggregate to recycling and agriculture rely on PU screens to achieve optimal results in particle classification and sizing.

Another notable advantage of PU screen technology is its resistance to clogging and blinding. The unique design of PU screens prevents material buildup and blockages, ensuring continuous operation and consistent throughput. This anti-clogging feature is particularly beneficial in applications where fine particles or sticky materials are present, as it minimizes downtime associated with manual cleaning and maintenance.

Furthermore, PU screens offer significant noise reduction compared to traditional screening materials, creating a quieter and more conducive working environment. This acoustic benefit is particularly relevant in industrial settings where noise levels can impact employee comfort and safety. By attenuating noise emissions, PU screens contribute to a healthier and more sustainable workplace.

The environmental sustainability of PU screen technology is another aspect worth highlighting. As a synthetic material, polyurethane can be recycled and repurposed, reducing the environmental footprint associated with screening operations. Additionally, the longevity of PU screens minimizes the need for frequent replacements, further conserving resources and reducing waste generation.

In summary, PU screen technology offers a myriad of benefits for industrial applications, ranging from durability and flexibility to performance and sustainability. Whether it’s PU screen mesh, PU moulding screen, or PU modular screens, these solutions have revolutionized the way industries approach screening processes. By investing in PU screen technology, businesses can optimize their operations, improve productivity, and achieve long-term cost savings.

One of the primary benefits of PU screen technology lies in its durability and resilience. Unlike traditional screening materials, PU screens are highly resistant to abrasion, impact, and wear, ensuring prolonged operational lifespan even in demanding environments. This durability translates to reduced downtime and maintenance costs, making PU screens a cost-effective choice for industrial applications.

Moreover, PU screens offer exceptional flexibility and versatility, allowing for seamless integration into various screening systems. Whether it’s pu moulding screen mesh or PU modular screens, these solutions can be customized to meet specific requirements, including size, shape, and aperture configurations. This adaptability enables precise control over the screening process, enhancing overall efficiency and product quality.

In addition to durability and flexibility, PU screen technology is known for its superior performance characteristics. The inherent properties of polyurethane, such as elasticity and resilience, contribute to efficient particle separation and screening accuracy. As a result, industries ranging from mining and aggregate to recycling and agriculture rely on PU screens to achieve optimal results in particle classification and sizing.

Another notable advantage of PU screen technology is its resistance to clogging and blinding. The unique design of PU screens prevents material buildup and blockages, ensuring continuous operation and consistent throughput. This anti-clogging feature is particularly beneficial in applications where fine particles or sticky materials are present, as it minimizes downtime associated with manual cleaning and maintenance.

Furthermore, PU screens offer significant noise reduction compared to traditional screening materials, creating a quieter and more conducive working environment. This acoustic benefit is particularly relevant in industrial settings where noise levels can impact employee comfort and safety. By attenuating noise emissions, PU screens contribute to a healthier and more sustainable workplace.

The environmental sustainability of PU screen technology is another aspect worth highlighting. As a synthetic material, polyurethane can be recycled and repurposed, reducing the environmental footprint associated with screening operations. Additionally, the longevity of PU screens minimizes the need for frequent replacements, further conserving resources and reducing waste generation.

In summary, PU screen technology offers a myriad of benefits for industrial applications, ranging from durability and flexibility to performance and sustainability. Whether it’s PU screen mesh, PU moulding screen, or PU modular screens, these solutions have revolutionized the way industries approach screening processes. By investing in PU screen technology, businesses can optimize their operations, improve productivity, and achieve long-term cost savings.