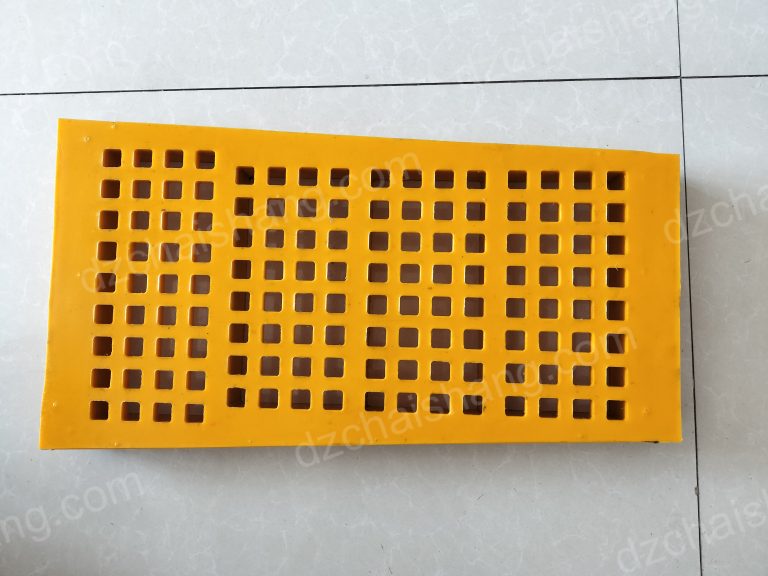

polyurethane mineral screens,polyurethane mine sieve screen mesh,polyurethane mesh screen

Exploring the Advantages of polyurethane mineral screens in mining Operations Polyurethane mineral screens, also known as polyurethane mine sieve screen mesh or…

Exploring the Advantages of polyurethane mineral screens in mining Operations

Polyurethane mineral screens, also known as polyurethane mine sieve screen mesh or polyurethane mesh screen, have become an integral part of modern mining operations. These screens are designed to separate and classify different sizes of materials, such as rocks, ores, and minerals, in the mining industry. The use of polyurethane in these screens offers several advantages that significantly enhance the efficiency and productivity of mining operations. One of the primary advantages of polyurethane mineral screens is their exceptional durability. Polyurethane is a robust material that can withstand the harsh conditions typically encountered in mining operations. It is resistant to abrasion, corrosion, and impact, which are common in the mining environment. This durability translates into longer service life for the screens, reducing the frequency and cost of replacements. In addition to their durability, polyurethane mineral screens also offer superior performance. They have excellent screening efficiency, thanks to their ability to maintain their shape under heavy loads. This characteristic allows them to effectively separate materials of different sizes, ensuring that the mining process is as efficient as possible. Furthermore, polyurethane screens have a low noise level, which contributes to a safer and more comfortable working environment. Another significant advantage of polyurethane mineral screens is their flexibility. Unlike metal screens, which can be rigid and inflexible, polyurethane screens can be manufactured in a wide range of shapes and sizes. This flexibility allows them to be customized to fit the specific needs of a mining operation, enhancing their effectiveness and efficiency. Polyurethane mineral screens also have a lower environmental impact than their metal counterparts. Polyurethane is a recyclable material, which means that when the screens reach the end of their service life, they can be recycled rather than discarded. This feature not only reduces the environmental footprint of mining operations but also contributes to cost savings, as the material can be reused. Moreover, polyurethane screens are lightweight compared to metal screens. This lightness makes them easier to install, handle, and transport, reducing the labor and equipment required for these tasks. Despite their lightness, however, they still offer the strength and durability necessary for effective screening in mining operations. Lastly, polyurethane mineral screens offer excellent cost-effectiveness. While they may have a higher initial cost than metal screens, their longer service life and lower maintenance requirements make them a more cost-effective choice in the long run. They also offer potential savings in terms of reduced noise pollution and environmental impact.

In conclusion, polyurethane mineral screens offer numerous advantages that make them an excellent choice for mining operations. Their durability, performance, flexibility, environmental friendliness, lightness, and cost-effectiveness all contribute to their growing popularity in the mining industry. As mining operations continue to seek ways to improve efficiency and reduce costs, the use of polyurethane mineral screens is likely to become even more widespread.

Lastly, polyurethane mineral screens offer excellent cost-effectiveness. While they may have a higher initial cost than metal screens, their longer service life and lower maintenance requirements make them a more cost-effective choice in the long run. They also offer potential savings in terms of reduced noise pollution and environmental impact.

In conclusion, polyurethane mineral screens offer numerous advantages that make them an excellent choice for mining operations. Their durability, performance, flexibility, environmental friendliness, lightness, and cost-effectiveness all contribute to their growing popularity in the mining industry. As mining operations continue to seek ways to improve efficiency and reduce costs, the use of polyurethane mineral screens is likely to become even more widespread.