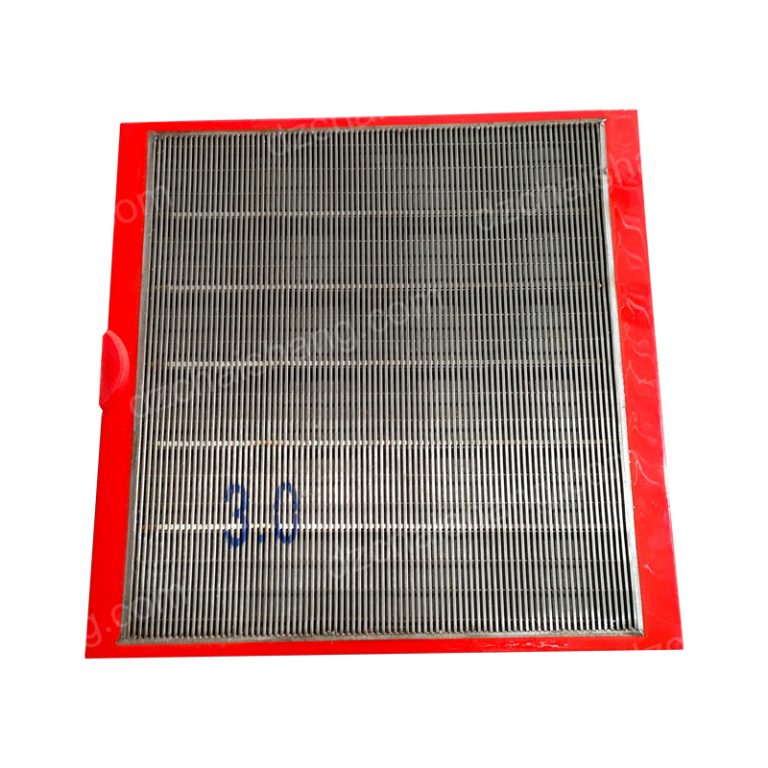

sieve iron ore pu vibrating linear screen mesh,vibrating mesh

Exploring the Efficiency of Sieve Iron Ore PU Vibrating linear screen mesh in Mineral Processing The mineral processing industry is a critical…

Exploring the Efficiency of Sieve Iron Ore PU Vibrating linear screen mesh in Mineral Processing

The mineral processing industry is a critical sector that significantly contributes to the global economy. One of the key components in this industry is the sieve iron ore PU vibrating linear screen mesh, also known as Vibrating Mesh. This innovative technology has revolutionized the way mineral processing is conducted, enhancing efficiency and productivity. The sieve iron ore PU vibrating linear screen mesh is a type of screening equipment that uses polyurethane (PU) as its primary material. Polyurethane is a versatile material known for its exceptional durability, flexibility, and resistance to abrasion, making it an ideal choice for screening applications. The pu screen mesh is designed to vibrate in a linear motion, effectively separating different sizes of particles in the mineral processing procedure. Moreover, the durability of the polyurethane material ensures that the vibrating mesh can withstand the harsh conditions often encountered in mineral processing. This includes exposure to abrasive materials and high temperatures. The resilience of the PU screen mesh translates to less downtime for maintenance and replacement, further boosting productivity.

The sieve iron ore PU vibrating linear screen mesh also offers excellent precision in mineral separation. The mesh can be customized to have different sizes of openings, allowing for the accurate separation of minerals according to their sizes. This precision is crucial in mineral processing as it ensures that the final product is of the highest quality.

Furthermore, the vibrating mesh is environmentally friendly. The use of polyurethane, a recyclable material, reduces the environmental impact of the mineral processing industry. Additionally, the high efficiency of the vibrating mesh means less energy is required for the screening process, contributing to a reduction in carbon emissions.

In conclusion, the sieve iron ore PU vibrating linear screen mesh is a game-changer in the mineral processing industry. Its high efficiency, durability, precision, and environmental friendliness make it an indispensable tool in the separation and processing of minerals. As the demand for minerals continues to grow, the role of innovative technologies like the vibrating mesh in enhancing productivity and sustainability becomes increasingly important.

Moreover, the durability of the polyurethane material ensures that the vibrating mesh can withstand the harsh conditions often encountered in mineral processing. This includes exposure to abrasive materials and high temperatures. The resilience of the PU screen mesh translates to less downtime for maintenance and replacement, further boosting productivity.

The sieve iron ore PU vibrating linear screen mesh also offers excellent precision in mineral separation. The mesh can be customized to have different sizes of openings, allowing for the accurate separation of minerals according to their sizes. This precision is crucial in mineral processing as it ensures that the final product is of the highest quality.

Furthermore, the vibrating mesh is environmentally friendly. The use of polyurethane, a recyclable material, reduces the environmental impact of the mineral processing industry. Additionally, the high efficiency of the vibrating mesh means less energy is required for the screening process, contributing to a reduction in carbon emissions.

In conclusion, the sieve iron ore PU vibrating linear screen mesh is a game-changer in the mineral processing industry. Its high efficiency, durability, precision, and environmental friendliness make it an indispensable tool in the separation and processing of minerals. As the demand for minerals continues to grow, the role of innovative technologies like the vibrating mesh in enhancing productivity and sustainability becomes increasingly important.