shaker tension Polyurethane screen Customization Dewatering,tension PU MediaSuppliers

How to Choose the Right Shaker Tension polyurethane screen for Your Application When it comes to selecting the right shaker tension polyurethane…

How to Choose the Right Shaker Tension polyurethane screen for Your Application

When it comes to selecting the right shaker tension polyurethane screen for your application, there are a few key factors to consider. The right screen can help you maximize efficiency and productivity, while the wrong one can lead to costly downtime and repairs. Here are some tips to help you choose the right shaker tension polyurethane screen for your application.

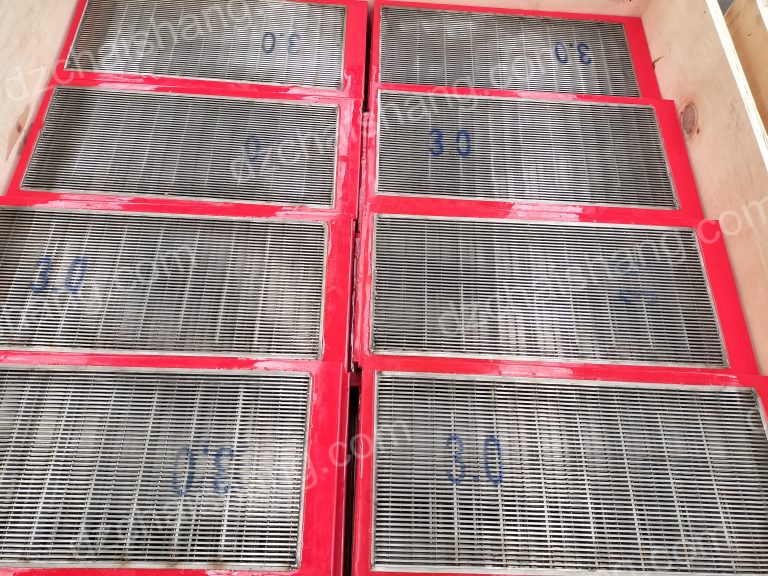

1. Consider the Material: The material of the screen is an important factor to consider. polyurethane screens are available in a variety of materials, including polyester, nylon, and polypropylene. Each material has its own unique properties and benefits, so it’s important to choose the one that best suits your application.

2. Consider the mesh Size: The mesh size of the screen is also an important factor to consider. The mesh size determines the size of the particles that can pass through the screen. If the mesh size is too small, it can lead to clogging and reduced efficiency. On the other hand, if the mesh size is too large, it can lead to a decrease in the quality of the product.

3. Consider the Tension: The tension of the screen is also an important factor to consider. The tension of the screen determines how much force is required to move the particles through the screen. If the tension is too low, it can lead to a decrease in efficiency. On the other hand, if the tension is too high, it can lead to excessive wear and tear on the screen.

4. Consider the Durability: The durability of the screen is also an important factor to consider. Polyurethane screens are designed to be durable and long-lasting, but some materials are more durable than others. It’s important to choose a material that can withstand the wear and tear of your application.

By considering these factors, you can ensure that you choose the right shaker tension polyurethane screen for your application. With the right screen, you can maximize efficiency and productivity, while avoiding costly downtime and repairs.

Benefits of Customizing Your Dewatering Tension PU Media for Maximum Efficiency

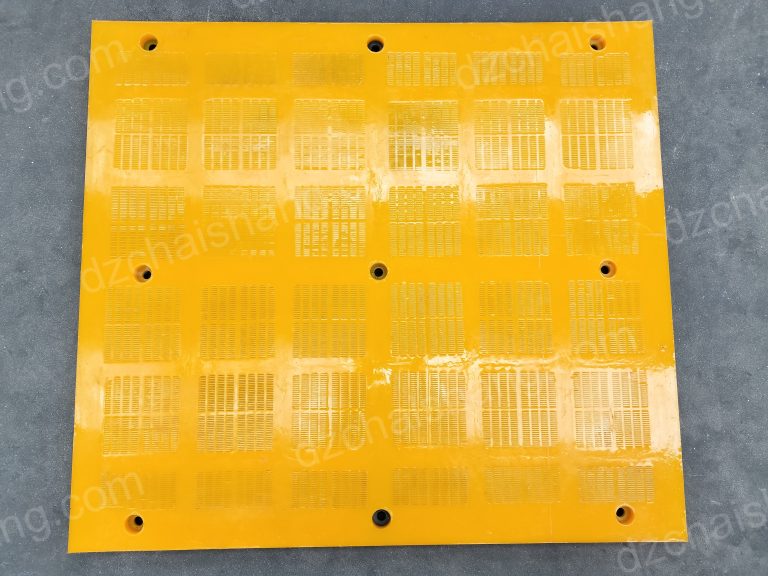

When it comes to dewatering, efficiency is key. Customizing your dewatering tension polyurethane (PU) media can help you maximize efficiency and get the most out of your dewatering process. Here are some of the benefits of customizing your PU media for maximum efficiency.

1. Improved Performance: Customizing your PU media allows you to tailor it to your specific needs. This means that you can optimize the media for your particular application, resulting in improved performance. You can also adjust the tension of the media to ensure that it is working at its best.

2. Reduced Maintenance: Customizing your PU media can help reduce the amount of maintenance required. By optimizing the media for your application, you can reduce the amount of wear and tear on the media, which can help extend its life.

3. Increased Efficiency: Customizing your PU media can help increase the efficiency of your dewatering process. By optimizing the media for your application, you can reduce the amount of energy required to operate the system, resulting in lower energy costs.

4. Improved Safety: Customizing your PU media can help improve safety in your dewatering process. By optimizing the media for your application, you can reduce the risk of accidents and injuries.

Customizing your PU media for maximum efficiency can help you get the most out of your dewatering process. By optimizing the media for your application, you can improve performance, reduce maintenance, increase efficiency, and improve safety. If you’re looking to maximize efficiency in your dewatering process, customizing your PU media is a great way to do it.