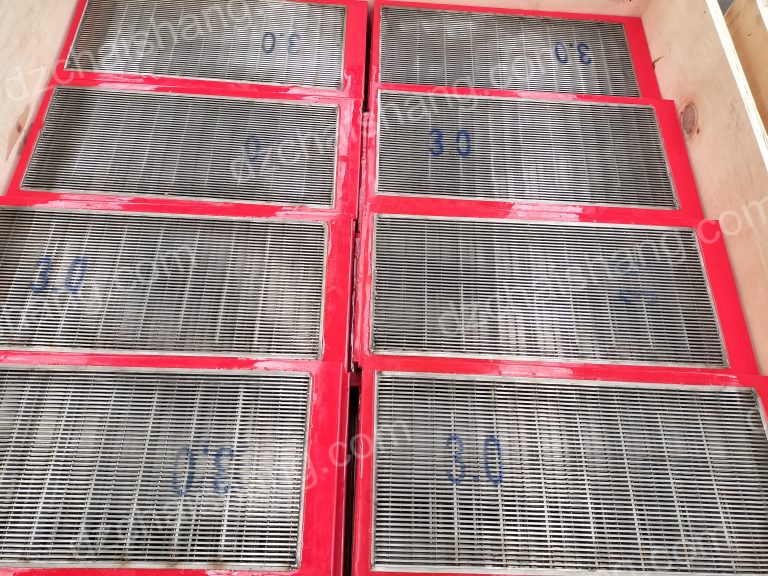

mining screen panels,mining pu polyurethane sizing screen

Exploring the Efficiency of mining screen panels in Mineral Extraction Mining screen panels, particularly those made from polyurethane (PU), have become an…

Exploring the Efficiency of mining screen panels in Mineral Extraction

Mining screen panels, particularly those made from polyurethane (PU), have become an integral part of the mineral extraction industry. These panels play a crucial role in the mining process, contributing significantly to the efficiency and effectiveness of mineral extraction. This article aims to explore the efficiency of mining screen panels in mineral extraction, focusing on the benefits of mining PU polyurethane sizing screens. Mining screen panels are used in the initial stages of mineral extraction. They are designed to separate the extracted material into different sizes, allowing for easier processing and sorting of valuable minerals. The efficiency of these panels is determined by their ability to accurately and quickly sort the extracted material, reducing the time and resources required for mineral extraction. One of the most popular materials used in the production of mining screen panels is polyurethane. This is due to its unique properties that make it ideal for use in the harsh conditions of a mining environment. Polyurethane is a highly durable material, resistant to wear and tear, and can withstand high levels of pressure and temperature. This makes it perfect for use in mining screen panels, as it can handle the heavy loads and harsh conditions that are common in mineral extraction. Mining PU polyurethane sizing screens, in particular, have proven to be highly efficient in mineral extraction. These screens are designed with a specific mesh size, which allows for precise sizing of the extracted material. This ensures that only material of the desired size passes through, reducing the amount of waste and increasing the efficiency of the extraction process. Furthermore, the durability of polyurethane ensures that these screens have a long lifespan, reducing the need for frequent replacements. This not only saves on costs but also reduces downtime, further increasing the efficiency of the mining process. In addition to their durability and efficiency, mining PU polyurethane sizing screens also offer a number of other benefits. For instance, they are lightweight and easy to install, reducing the time and effort required for installation. They also offer excellent noise and vibration reduction, contributing to a safer and more comfortable working environment. Moreover, polyurethane is a flexible material, allowing for the production of mining screen panels in a variety of shapes and sizes. This means that they can be customised to fit any type of mining equipment, further enhancing their efficiency and versatility.

In conclusion, mining screen panels, particularly those made from polyurethane, play a crucial role in the efficiency of mineral extraction. They offer a number of benefits, including durability, precision sizing, and versatility, making them an ideal choice for use in the mining industry. As the demand for minerals continues to grow, the importance of efficient and effective mining processes cannot be overstated. Therefore, the use of mining PU polyurethane sizing screens is likely to continue to grow, contributing to the ongoing development and success of the mineral extraction industry.

Moreover, polyurethane is a flexible material, allowing for the production of mining screen panels in a variety of shapes and sizes. This means that they can be customised to fit any type of mining equipment, further enhancing their efficiency and versatility.

In conclusion, mining screen panels, particularly those made from polyurethane, play a crucial role in the efficiency of mineral extraction. They offer a number of benefits, including durability, precision sizing, and versatility, making them an ideal choice for use in the mining industry. As the demand for minerals continues to grow, the importance of efficient and effective mining processes cannot be overstated. Therefore, the use of mining PU polyurethane sizing screens is likely to continue to grow, contributing to the ongoing development and success of the mineral extraction industry.