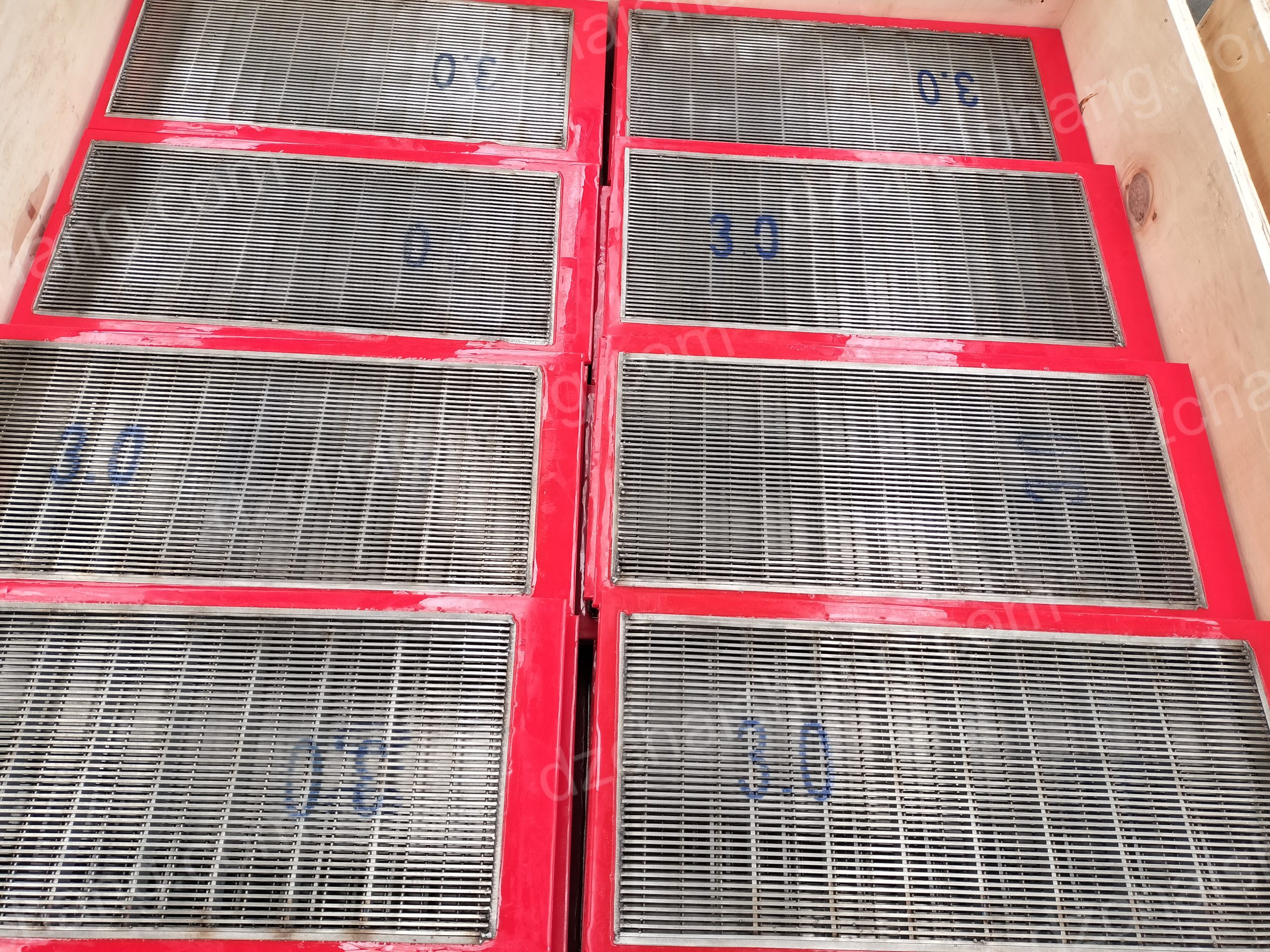

Hot selling vibrating screen panels,wear resistance security screen mesh

Innovations in vibrating screen panels: Enhancing Efficiency and Durability **Title: hot selling vibrating screen panels, Wear Resistance Security screen mesh** Innovations in…

Innovations in vibrating screen panels: Enhancing Efficiency and Durability

**Title: hot selling vibrating screen panels, Wear Resistance Security screen mesh** Innovations in the design and manufacturing of vibrating screen panels have significantly elevated their efficiency and durability, positioning them as pivotal components in various industrial applications. Vibrating screens, essential for the sorting and sizing of materials, now incorporate advanced materials and engineering techniques that not only enhance their performance but also extend their lifespan. The latest developments in vibrating screen technology focus heavily on the use of wear-resistant materials. The introduction of specialized rubber and polyurethane as alternatives to traditional steel screens marks a substantial advancement. These materials are not only highly resistant to abrasion but also offer reduced noise levels and improved safety. This shift is particularly beneficial in industries such as mining and quarrying, where durability and operational efficiency are paramount. Moreover, these innovative materials bring an added advantage of flexibility which allows the screens to absorb impact and reduce the clogging caused by smaller particles. This flexibility ensures a more efficient sieving process and a higher quality of material output. The integration of these materials into screen designs demonstrates how industry requirements drive technological advancement, pushing manufacturers to develop solutions that address specific operational challenges. Transitioning from material innovations, the structure of the screen panels has also seen significant enhancements. The latest designs feature improved fastening systems that simplify the installation and replacement process. These user-friendly configurations not only save valuable time but also minimize downtime, enhancing productivity. Enhanced fastening systems ensure that screen panels remain securely in place, even under high-vibration conditions, thereby preventing premature failures and maintaining consistent performance. Another pivotal innovation in the design of vibrating screen panels is the incorporation of customized aperture configurations and shapes. Modern screens can be tailored to meet unique processing requirements, optimizing the screening process for different materials. The ability to customize the mesh size and shape allows for improved sorting accuracy, which is crucial in industries where material specifications are stringent. Security is another aspect that has received considerable attention in the development of these screens. The wear-resistant security screen mesh now includes additional features to prevent environmental damage and ensure operator safety. For instance, some mesh designs incorporate anti-blinding properties, which not only maintain clear visibility through the screen but also prevent the accumulation of materials that could impede the screening process. The impact of these innovations extends beyond simple functionality. By enhancing the durability and efficiency of vibrating screen panels, manufacturers have also contributed to the sustainability of operations. Longer-lasting materials and improved operational efficiency mean that less energy is consumed and waste is minimized. This not only reduces the operational costs for businesses but also contributes to broader environmental conservation efforts. As industries continue to demand higher performance and durability from their screening equipment, the advancements in vibrating screen panel technology are set to play a crucial role. By focusing on wear resistance, enhanced security features, and operational efficiency, these innovations not only meet the immediate needs of businesses but also pave the way for future developments in industrial screening technology. These continuous improvements are essential for industries looking to optimize their processes and achieve higher throughput with minimal downtime.Exploring Wear Resistance in Security Screen Mesh: Applications and Benefits

**Hot Selling Vibrating Screen Panels, Wear Resistance Security Screen Mesh** In the realm of industrial applications, the durability of materials is paramount, especially for components like vibrating screen panels and security screen mesh. These items are crucial in a variety of settings, from mining and construction to manufacturing and security. The focus on wear resistance in such materials is not merely a matter of durability, but also of efficiency and security, enhancing the operational lifespan and reliability of the machinery and facilities they are part of.Vibrating screen panels are primarily used in sorting and processing operations across different industries. These panels are subjected to continuous vibrations, abrasive materials, and overall harsh environments during their operation. The demand for wear-resistant vibrating screen panels has surged, driven by industries that require reliable and efficient sorting mechanisms. These panels are often made from rubber or polyurethane; materials chosen for their ability to withstand wear and tear much longer than their metal counterparts. This not only reduces the frequency of replacements but also minimizes downtime, a critical factor in maintaining productivity.

Transitioning from the industrial backdrop to security applications, wear resistance plays a similarly crucial role in the composition of security screen mesh. This type of mesh is essential for providing safety and security in residential and commercial spaces. It is designed to resist cuts, tears, and other forms of damage that could compromise a barrier’s integrity. The mesh is commonly composed of stainless steel, which offers a high resistance to corrosion and wear. This durability ensures that the security screen remains effective over a long period, even when exposed to environmental elements such as moisture and UV radiation, which are known to degrade less robust materials. Moreover, the wear resistance of security screen mesh provides additional benefits beyond longevity. It contributes to a screen’s overall strength and makes it difficult for intruders to breach, adding a layer of security that is visually subtle yet highly effective. The robust nature of these screens also means they can provide a clear view from the inside and allow for the passage of light and air, maintaining the aesthetics and comfort of the environment they protect. The benefits of investing in wear-resistant materials for vibrating screen panels and security mesh are manifold. For industries that rely on these components, the cost-effectiveness of investing in durable materials is clear. They not only save on costs related to replacements and repairs but also improve operational efficiency by reducing the downtime associated with maintenance. Additionally, the enhanced security features afforded by high-strength mesh make it an invaluable component in safeguarding premises against unauthorized access. In conclusion, the integration of wear-resistant materials in the design and manufacture of vibrating screen panels and security screen mesh presents significant advantages. Whether in the harsh environment of an industrial plant or securing a home against intruders, these materials stand as pivotal elements in modern machinery and security systems. As technology advances, the development of even more durable materials continues, promising to further enhance the efficiency and security of these essential components. This not only underscores the importance of material science innovation in industrial and security applications but also highlights the ongoing commitment to improving safety and productivity across various sectors.