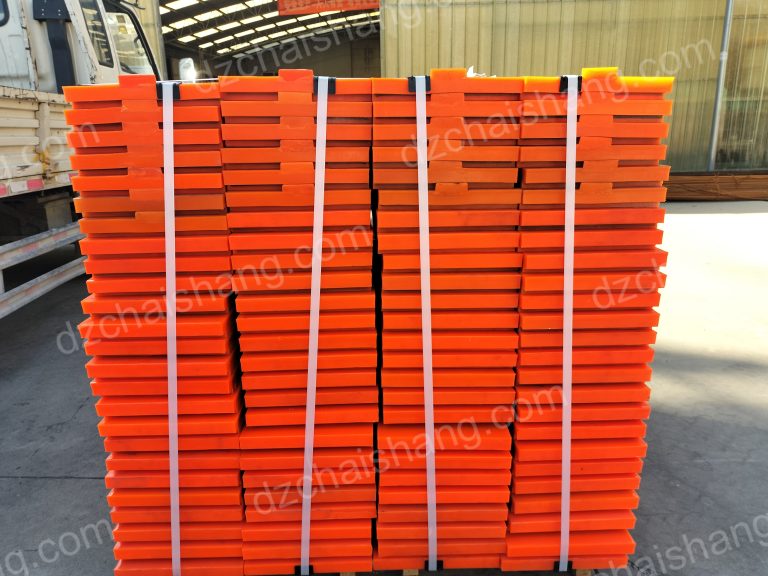

Polturethane screen panel Vibrating Screen Mesh for your customization

Benefits And Applications Of polyurethane screen panels In vibrating screen mesh Customization Polyurethane screen panels are an essential component in the mining…

Benefits And Applications Of polyurethane screen panels In vibrating screen mesh Customization

Polyurethane screen panels are an essential component in the mining and aggregate industries, where they are used in vibrating screen mesh customization. These panels are made from a highly durable material known as polyurethane, which offers several advantages over traditional materials such as steel or rubber. The benefits of using polyurethane screen panels in vibrating screen mesh customization are numerous, making them a popular choice for many industrial applications.One of the primary benefits of polyurethane screen panels is their exceptional durability and wear resistance. Polyurethane is a highly resilient material that can withstand the harsh conditions often encountered in mining and aggregate processing. This includes exposure to abrasive materials, heavy impacts, and corrosive environments. As a result, polyurethane screen panels have a longer lifespan compared to other materials, reducing the need for frequent replacements and lowering maintenance costs. In addition to their durability, polyurethane screen panels also offer superior performance in terms of screening efficiency. The flexibility of polyurethane allows for more effective vibration and movement of the screen, which enhances the screening process. This results in a higher quality of screened material, with fewer fines and contaminants. The improved screening efficiency also leads to increased productivity, as more material can be processed in a shorter amount of time. Another advantage of polyurethane screen panels is their noise reduction capabilities. The material’s inherent properties help to dampen noise and vibrations, creating a quieter working environment. This is particularly beneficial in settings where noise levels are a concern, such as near residential areas or in facilities where workers are exposed to constant noise. Polyurethane screen panels are also highly customizable, allowing them to be tailored to specific applications and requirements. They can be manufactured in various sizes, shapes, and configurations to fit different types of vibrating screens. This level of customization ensures that the panels are optimized for the specific screening process, leading to better performance and efficiency. The applications of polyurethane screen panels in vibrating screen mesh customization are diverse and span across multiple industries. In the mining industry, they are used for the screening of minerals and ores, such as coal, iron ore, and gold. In the aggregate industry, they are employed in the screening of sand, gravel, and crushed stone. Polyurethane screen panels are also used in other industries, such as recycling, where they help to separate recyclable materials from waste. Furthermore, the environmental impact of polyurethane screen panels is relatively low compared to other materials. Polyurethane is a recyclable material, and its long lifespan reduces the frequency of replacements, thereby minimizing waste. Additionally, the improved screening efficiency achieved with polyurethane screen panels can lead to reduced energy consumption, as less power is required to process the same amount of material. In conclusion, polyurethane screen panels offer a range of benefits that make them an ideal choice for vibrating screen mesh customization. Their durability, performance, noise reduction capabilities, and customizability, combined with their applications across various industries, make them a valuable asset in industrial screening processes. As technology continues to advance, it is likely that the use of polyurethane screen panels will become even more widespread, further enhancing their impact on the efficiency and sustainability of industrial operations.

Comparing Polyurethane Screen Panels With Other Materials For Enhanced Vibrating Screen Mesh Performance

Polyurethane screen panels are increasingly becoming the preferred choice for vibrating screen mesh applications due to their exceptional durability and efficiency. When compared to other materials such as wire mesh or rubber, polyurethane offers superior performance in terms of wear resistance, noise reduction, and overall cost-effectiveness. This makes it an ideal solution for industries that require high-quality screening solutions, such as mining, quarrying, and recycling. One of the key advantages of polyurethane screen panels is their exceptional wear resistance. Unlike wire mesh, which can easily become worn and require frequent replacement, polyurethane is highly resistant to abrasion and can withstand harsh conditions for extended periods. This durability not only reduces maintenance costs but also minimizes downtime, ensuring continuous operation and increased productivity. Additionally, polyurethane’s resistance to corrosion and various chemicals further enhances its longevity, making it suitable for use in a wide range of environments. Another significant benefit of polyurethane screen panels is their ability to reduce noise levels during operation. Vibrating screens can generate considerable noise, which can be disruptive and pose health risks to workers. Polyurethane, with its inherent sound-dampening properties, helps to absorb and dissipate sound, creating a quieter and safer working environment. This is particularly important in settings where noise regulations are stringent, and maintaining a low decibel level is crucial. Furthermore, polyurethane screen panels offer superior screening efficiency compared to other materials. The flexibility of polyurethane allows for more effective vibration, which enhances the screening process and improves the quality of the separated materials. This is especially beneficial in applications where precise particle size separation is required. Additionally, Polyurethane Panels can be customized with various aperture shapes and sizes, providing greater versatility and allowing for optimal performance tailored to specific screening needs. Cost-effectiveness is another area where polyurethane screen panels excel. Although the initial investment in polyurethane may be higher than that of wire mesh or rubber, the long-term savings are significant. The extended lifespan of polyurethane panels means fewer replacements are needed, reducing both material and labor costs. Moreover, the improved screening efficiency can lead to higher throughput and better-quality products, further enhancing profitability. In conclusion, when comparing polyurethane screen panels with other materials such as wire mesh or rubber, it is clear that polyurethane offers numerous advantages that can significantly enhance the performance of vibrating screen mesh. Its exceptional wear resistance, noise reduction capabilities, screening efficiency, and cost-effectiveness make it an ideal choice for a wide range of industries. By opting for polyurethane screen panels, businesses can achieve improved operational efficiency, reduced maintenance costs, and a safer working environment, ultimately leading to increased productivity and profitability. As such, polyurethane screen panels are a smart investment for any organization seeking to optimize its vibrating screen mesh applications.